Procurement and Availability

The role of the Supply Chains group (Procurement, Operations Planning and Logistics) is to provide Availability of finished products that satisfies customers’ demand. The lead role of Procurement is to enhance that capability through providing Availability of input items.

When asked about the role of Procurement (or Purchasing), most people will answer ‘buys things’. But, no matter the buy cost, every material, ingredient, intermediate good and item purchased for resale must be available as required. When not available, even a low cost item will have a much higher value to the business, in terms of sales revenue that has been lost.

To better ensure Availability of input items is likely to be achieved and so protect the gross margins, the need is to understand and reduce the external risks to the business. This activity is within the scope of Sourcing inputs for the business and managing the many relationships and links of Procurement.

Quantify Risks

With many uncertainties influencing responses in a connected world, Procurement must identify, understand and quantify these uncertainties as risks attached to the supply of input items and services. This is especially important for inputs from a single source supplier, country or geographical cluster. Global supply risks can also exist within domestic sourced items, as they will often contain materials and intermediate goods that are manufactured internationally, but sold domestically by agents and importers.

To understand and mitigate risks requires Procurement professionals to have a thorough understanding of the organisation’s supply markets and the climate zones they operate within. This is formalised by the Supply Chains group through development of the Supply Chains Network Design Map. Inputs by Procurement to the Map include:

- Information concerning each supplier, their risks and dependencies at Nodes and Links in the supply network

- ‘Revenue at Risk’, which identifies the revenue value of Procurement risks on future sales

- Supply Markets Intelligence, which highlights potential future influences, and therefore risks, in the supply markets which affect the organisation

- Climate and Environment, Social and Governance (ESG) regulations and risks, which may influence the Procurement of items. Examples are: Scope 3 emissions liability; requirement to design for reuse, repair and refurbish; a ‘right to repair’ for products and ‘Return and Earn’ schemes for consumers

A myth of globalisation has been that low production labour costs means the cost of the finished product is also low. However, the costs of accommodating Complexity, Variability and Constraints in global supply chains means that the ‘total cost of ownership’ (TCO) can be high.

Identifying the Uncertainties, then calculating the risks for a business should influence a change in Procurement’s approach to Tier 1 suppliers. But, a few recent surveys have identified a return by some businesses in developed countries to traditional Procurement methods of ‘cost down’ and ‘lowest unit price’. But these factors should receive a reduced emphasis and instead, there needs to be an increased emphasis on the TCO.

In addition to the purchase price, TCO will include the costs associated with: location risks (of the supply facility), low reliability of delivery (responsive or flexible), limited visibility (through the extended supply chain) and lack of sustainability. An aspect of reducing the TCO is to develop a more collaborative relationship with suppliers that have a high risk factor.

Understanding the factors built into the Map of your organisation’s supply markets enable an assessment of the vulnerability and resilience to supply for the Supply Chains Network. This is an integral part of the Procurement Strategy, which positions supplier relationships as a core business strength.

However, organisations are likely to not be as knowledgeable about their Supply Chains Network as they may imagine; in particular, the risks associated with countries, locations and third-party production and distribution. A task may be contracted or a function outsourced, but the risks are not.

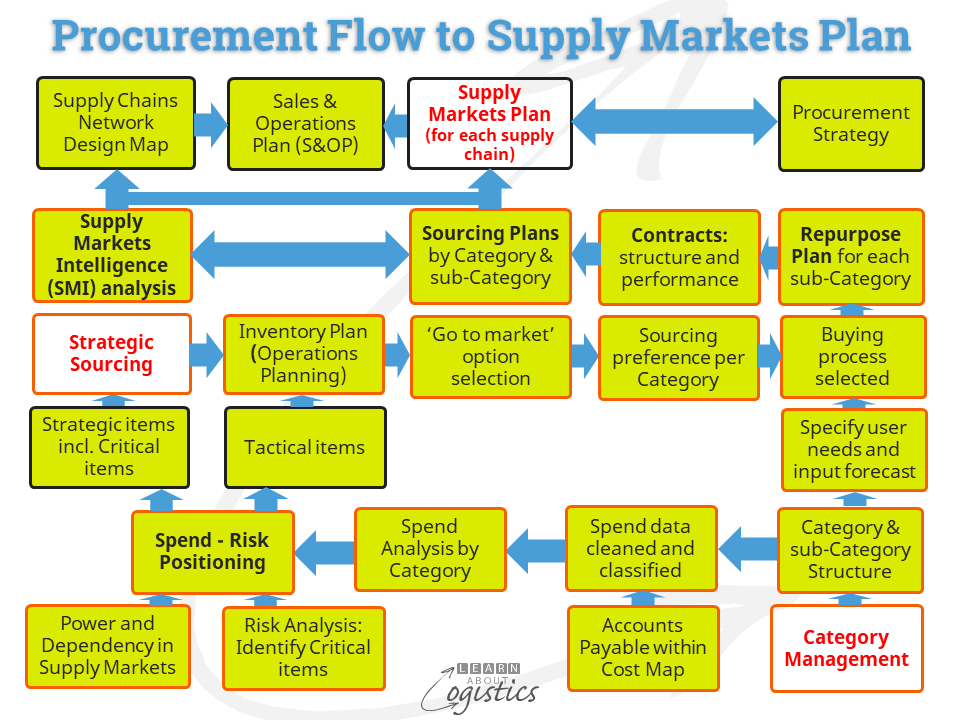

The diagram illustrates the Sourcing process. This is the flow through Procurement to the Supply Markets Plan, which is input to the Sales & Operation Plan (S&OP). The Buying and Contracts stage of Procurement follow acceptance of the S&OP.

Knowledge and Skills

If, as argued in this blogpost, the role of Procurement is the management of external risks and that ‘buying things’ is an outcome from risk management, what are the knowledge and skills required of Procurement professionals? An indication of the range is:

People skills

- Management of relationships with suppliers and internal customers (including supplier development)

- Communication and interpersonal skills that influence peoples’ behaviour for effective performance

- Collaborative problem-solving (which involves creative thinking). Respond to the challenges of uncertain supply markets and the digitalization of supply businesses

Analytical skills

- Finance: Cash flow and working capital requirements of supply chains through the buying cycle; Financing of supply chains; Cost Accounting; Budgets; Commodity Futures markets and structure a Business Case

- Risk Management

- Use digital tools at a competent user level (digital fluency). Use at an advanced user level for Procurement Analysts working at the tactical level of Buying and Contracts

Procurement skills

- Outsourcing and Offshoring analysis and implementation, including the effects of ‘free trade’ agreements (FTAs), also called ‘preferential’ trade agreements

- Category Management (including Spend Analysis)

- Sourcing Research and Analysis

- Procurement professionals should not be an ‘expert’ in a Category (such as IT). When negotiating to buy items, a competent user can ask more probing questions of a seller, whereas an ‘expert’ it less willing to ask the ‘dumb’ questions, because they are assumed to know the answer

- Cost drivers in supplier industries, especially those that are fragmented, consolidating, oligopolies or regulated

- Forecast industry trends and potential influences on strategic supplier relationships

- Legislative and Policy understanding. Procurement outcomes are consistent with relevant international and domestic legislative, probity and policy requirements, such as those relating to ESG (environment, social and governance)

- Negotiating purchase agreements

- Procurement Contracts: Legal Issues; Contract Writing. Contracts skills have ‘whole-of-life’ contract planning capability extended to include Project Management (scoping a project, setting goals and execution)

A Procurement Manager is unlikely to possess all the skills required at the professional level. However, a good leader knows the skills required and builds the Procurement team around those requirements, while encouraging all staff to upgrade their knowledge and capabilities.