Planning is a macro view

Planning roles have always been analytical, but there is now an increasing emphasis on working with system applications and tools to assist the integration of transaction data with annual budgets or ERP outputs. With the increasing ease of re-running Operational models, the objective of Planning appears to be output that is accurate and fast. But this is an incorrect view of Planning.

An additional hurdle for Planning is the current scope, identified in too many articles, of planning an organisation’s ‘end-to-end’ supply chains. But ‘end-to-end’ is not defined. Is it the Core supply chains between Tier 1 customers, the organisation and Tier 1 suppliers? Or is it the Core plus Extended supply chains between the end user and the farms and mines from where materials originate? But recognise, that unless Tier 1 suppliers (and their suppliers) and Tier 1 customers are owned, controlled or strongly influenced by the organisation being planned, the second option is an unlikely possibility.

A sales objective for technology businesses is to sell high in a customer’s organisation, therefore the outcome can be ‘solutions’ imposed by senior management. This can lead to an unnecessary use of technologies, rather than commencing with a consideration of what customers require from the supply chains of their suppliers.

This is the macro approach of Planning – to consider the broader picture. Planning requires collaboration between stakeholders to gain a consensus plan from the macro level data, options and probabilities presented. The plan is then expanded when scheduling Operations – the level where SKU data is analysed using computing applications. To differentiate between the two, the activity should be titled Operations Planning & Scheduling.

Planning process

As a business grows nationally or internationally, it will likely become more complex, with additional constraints through supply, manufacturing and distribution. As noted in previous blogposts, Planning is thinking into the future regarding the activities required to achieve a desired goal. The goal is to be Effective in serving the customers. This does not require an assumption of complexity that requires lots of computer applications to overcome.

In the Planning process, the current Plan is for future periods that commence after the designated ‘freeze’ period. Inputs to planning are assumptions about the future, which can change due to unexpected events. Each period, the Plan is updated to reflect the new assumptions and more current inputs. This shows the importance of collaboration between affected groups (stakeholders) to better understood the inputs and influences, which enable agreement on the Plan. The process of planning is therefore more important than the accuracy of the Plan.

The process by which the Plan is produced is called Sales & Operations Planning (S&OP). The critical role for Operations Planning is to facilitate this tactical planning process. It establishes the future direction for Operations and the Plan becomes an input for Scheduling Operations.

Importantly, S&OP is a collaboration process, NOT a software driven process. However, the process can be improved by using specialist software that assists with analytics, building scenarios and answering ‘what if’ questions. It is important to recognise that S&OP is not:

- The strategic business plan

- A budget review. S&OP is a planning process, while budgets are an annual financial positioning exercise. S&OP must not be constrained by the budget; however, decisions from S&OP can be an input to budget updates

- A weekly or bi-weekly Operations Scheduling meeting concerning performance

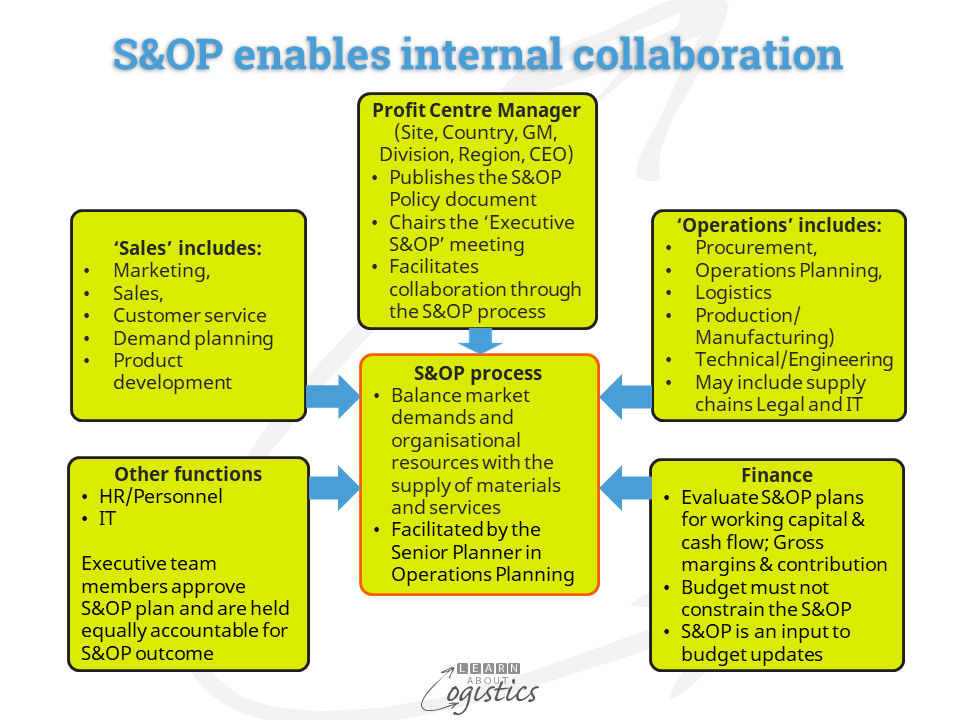

The groups that collaborate through the S&OP process are shown in the diagram below.

The senior planner in Operations Planning is the facilitator of the S&OP collaboration process. Within each month, or four week planning period, each of the review meetings and the final Executive S&OP meetings are short – with practice, they become limited to one hour, because attendees know the format and the data required to be discussed. The role of the Operations Planning facilitator is to gain an understanding from the participants of the possible trade-offs between conflicting approaches, so the focus of each meeting is on the important.

The objective of S&OP is to enable a balance between expected future demands for the organisation’s products and services, the organisation’s internal resources and the supply of purchased or intra-company provided items. Also, that decisions from the S&OP process can be financed.

Drive the S&OP outcome

The important elements that will govern the S&OP outcome are: customer demand; constraints; margins; and the building blocks for scheduling the flow of items – capacity; inventory and lead times.

Giving Operations Planning the responsibility for balancing capacity, inventory and lead times is the first step in changing an organisation from function (or silo) thinking to thinking about flows – of items, money, data and information. The Capacity, Inventory and Lead Time Plans are re-evaluated within each period S&OP process.

This step allows Operations Planning to quantify the trade-offs and demonstrate how the interconnection and interactions of capacity, inventory and lead times influences reliable, on-time delivery of products to customers. This is also important for understanding the possible constraints imposed by outsourcing production to contract manufacturers and obtaining production volume and component supply from low-cost countries.

Capacity needs in a business can change depending on the: product mix, demand levels, volatility of demand, order priorities, production efficiency, distribution effectiveness. and order-to-delivery lead times. Capacity requirements can also be influenced by:

- the time required to change (or flex) capacity

- demand uncertainty, requiring probability ranges to be incorporated into sales forecasts

- capacity requirements against inventory form and function decisions (for both raw materials and finished goods) and

- in-transit inventories that may affect inbound/outbound order-to-delivery lead times

The S&OP process is also informed by the macro operational performance:

- Future delivery performance. Measured by the probability of ‘delivery in full, on time, with accuracy’ – DIFOTA;

- Provide Availability for customers. Achieving the Plan – S&OP, S&OE and Execution Schedules;

- Minimise Uncertainty through the identification and management of risk, including functions that are outsourced

Too often, Tactical Planning is not done as a formal process, as a business relies on the budget or the ERP Master Schedule to be the guide for production and distribution schedules. In these circumstances, the role of a group called Operations Planning (or similar) is only concerned with scheduling operations. However, to serve customers effectively requires implementing Tactical Planning via S&OP, so that teams are aligned with outcomes, which enables a unified approach to serving customers.