Strategy and Tactics

It is assumed by commentators that few businesses have developed a Supply Chains Network strategy. This may be due to the continuing perception that all elements of supply chains are cost based and therefore, the main role of managers employed in the area is to reduce or eliminate costs.

The opposite view is that a business exists to add value to purchased items, such that customers and consumers perceive value from the price they are prepared to pay. This approach requires managers to identify and work with the most effective flows and processes to achieve value. It also requires a business to develop its strategy for the purchase, movement and storage of materials and products. However, in businesses there can be confusion between strategy and tactics, with the term ‘strategy’ too often used when referring to current plans.

Strategy is about developing the best plan for achieving the long-term objectives and goals of an organisation. Therefore, a strategy can remain the same for a reasonably long period into the future (e.g. 5-8 years). It is the responsibility of senior level management to create the corporate strategy based on approved functional strategies developed from the Business Plan.

Tactics are the response of the organisation for implementing the strategy and to changes in the external environment and conditions – economic, geopolitical and business markets (both sales and supply). Typically, middle-level management have responsibility for implementing and achieving the tactics.

Supply Chains and Network

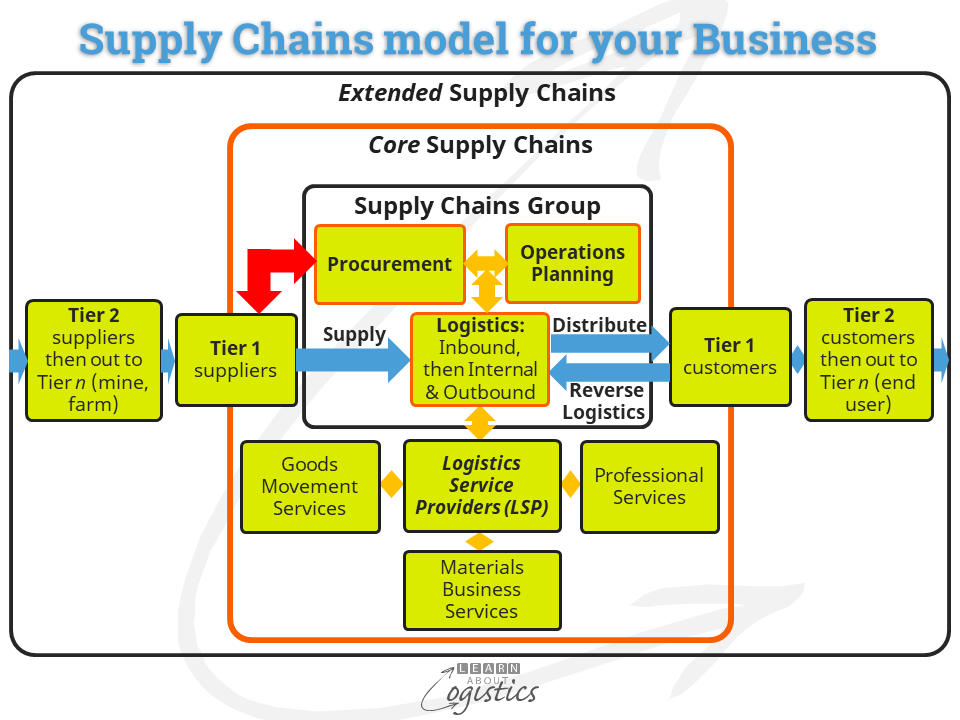

Now that the term ‘Supply Chain’ is more often used in the media, it requires a definition. That used by LAL (adapted from Supply Chain Insights) is: Effective flows of items, money, information and data which aligns the organisation to serve its customers’ customers, through the design of processes from the sales channel to the suppliers’ suppliers, providing value for end users at the lowest total cost. An organisation can have a number of inbound and outbound supply chains based on the model shown below.

Supply Chains Network: The multiple supply chains that comprise an organisation’s network of interdependent, but potentially connected, suppliers and customers.

The pressures and influences on your organisation’s supply chains form a hierarchy of Uncertainty This can be modelled to identify the range of Risks, which is a core capability within an organisation’s Supply Chains group.

In addition to Uncertainty, an organisation must recognise that its Supply Chains Network is a complex, non-linear system that adapts to changes, interruptions and disasters without a centre of control. The outcomes are both Emergent and Cumulative, over which an organisation’s management has little control. Therefore, the Network can only be marginally improved by a focus on optimizing activities and reducing costs in an organisation’s operating functions.

Consolidate individual Strategies

There are three core functions that together form the Supply Chain group. Each have their own strategy, which are consolidated to form an organisation’s Supply Chains Network strategy:

- Procurement strategy addresses the corporate and external factors that influence commercial relationships with suppliers. Also, the factors that potentially affect the availability of supply through the extended supply chains

- Operations Planning strategy addresses how to effectively add value to the purchased materials, whether internal, at contract producers or test and pack facilities within 3PL warehouses. This is to provide Availability of goods and services that meet customer and end user demands at the lowest total cost

- Logistics strategy considers the objective to provide Availability of items (and associated services) through the Core inbound, internal and outbound supply chains.

Procurement, Operations Planning and Logistics are what an organisation does, with Availability as its objective. A Supply Chain is the environment that influences how items are purchased, planned, moved and stored. Supply Chains cannot be managed, only the relationships within them.

Given the Supply Chains Network strategy is a consolidated document, it requires an overview that identifies emerging market dynamics and the extent to how the strategy will support the business strategy. It will incorporate a multi-year timeline of events for building capabilities to implement the strategy. Examples of the elements to consider are:

- Climate change and its possible influence of trade lanes;

- Geopolitics and its possible influence on trading relationships and the supply of ‘critical’ materials

- Potential changes to the balance of power and dependency through the Supply Chains Network

- Potential changes to the structure of supply chains that could affect organisation

- Changes in technologies and processes and their potential influence on the organisation’s Supply Chains group and its supply chains

Availability through Supply Chains

The above elements are considered under the overall objective of the Supply Chains group, which is to provide ‘Competitive Availability’. The definition of Availability within supply chains is: the time-related positioning of internal and external resources to provide goods and services for customers at the lowest total cost. This addresses products on a supermarket shelf, a boring machine for an underground tunnel, or spare parts for a vehicle; all of which require Availability across three areas:

- Physical Availability: refers to ‘items on the shelf’ – the right product at the right place at the right time

- Operational Availability refers to the availability of assets; say a machine to enable production of a product. This is Logistics Support. Should the machine not work, it may need parts, which relies on planning the physical availability of service parts

- Continuous Availability is concerned with demands for the use of logistics infrastructure; for example, energy infrastructure, transport infrastructure and Cloud IT availability

Availability can be influenced and affected by Uncertainty in sales and supply markets; at customers; internally; at contractors and at suppliers. The level of Uncertainty is influenced by the amount of:

- Complexity of administrative and physical processes at customers, internally, contractors and suppliers

- Constraints that limit achievement of the Availability objectives through supply chains. Examples are:

- location decisions based on volume to weight and value to weight ratios of products and materials,

- location decisions based on inventory form and function

- throughput limitations due to equipment specifications

- product security requirements

- Variability in demand, markets, and lead times

A matrix approach

An approach to identifying the needs within a Supply Chains Network strategy is based on a matrix that was developed within Hewlett Packard. On the y axis, identify your selection of (say) four attributes that best describe the Availability objectives of your organisation. For example, Slack et al (2004) defined the attributes as speed, quality of the process, flexibility, dependability and cost. However, the attributes of Availability (or time and place) can be constrained by:

- Where in a supply chain the business is located i.e. primary industry; producer, converter; fabricator; assembler; retailer (or other end use sales outlets)

- Limitations on the handling and storage of products and materials

- The qualifiers required prior to the sales or supply process

- The factor(s) on which sales and supply orders are awarded

Then, on the x axis, place the main elements for developing your supply chains, such as:

- Improving business relations with customers and suppliers

- Capacity availability in the Supply Chains Network

- Organisation structure to address supply chain resources and capabilities

- Develop people who work in the organisation’s supply chain functions

- Acquiring or developing supply chain information technologies and processes

Complete the matrix; however, not all cells need to be completed, nor are all cells of equal importance – they can be colour coded.

In summary, your organisation’s Supply Chains Network strategy is a consolidation of strategies pinned together by an holistic view of demand, product availability and supply processes; with an emphasis on sales and supply market dynamics and changes in potential changes in the power and dependency within business relationships.