Supply Chains in your business

Supply Chains are not new; they have existed since people commenced trading items for barter or money; but Supply Chains cannot be managed. Instead, consider them as a description of the environment in which the activities of Procurement, Operations Planning and Logistics (your Supply Chain group) are required to operate.

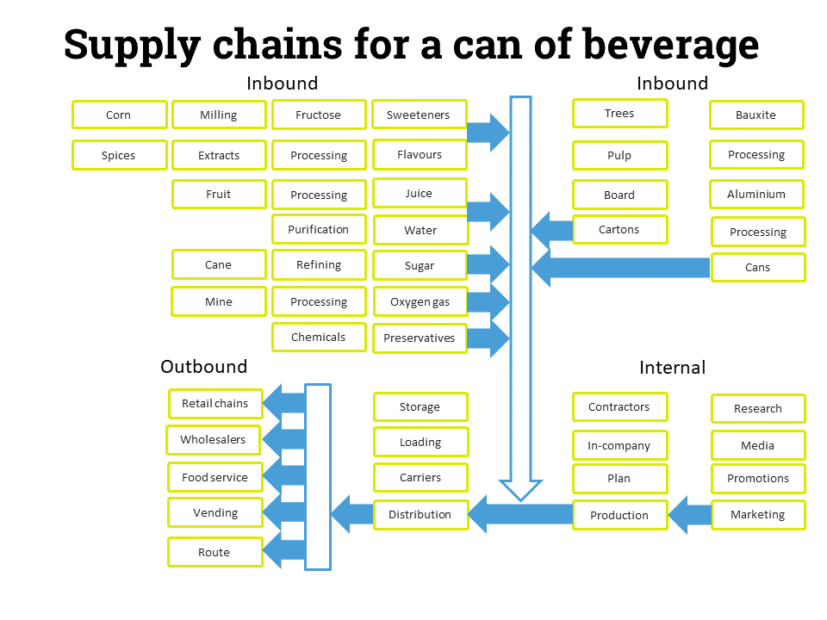

A supply chain is identified by similarities in the production and distribution process for a group of items. A business, industry and economy will have multiple supply chains.. The diagram below illustrates that a business selling a beverage in cans has seven inbound supply chains and five outbound supply chains. But, it is common in the media (and academic papers) of referring multiple supply chains in a business or industry as ‘the supply chain’. This is incorrect.

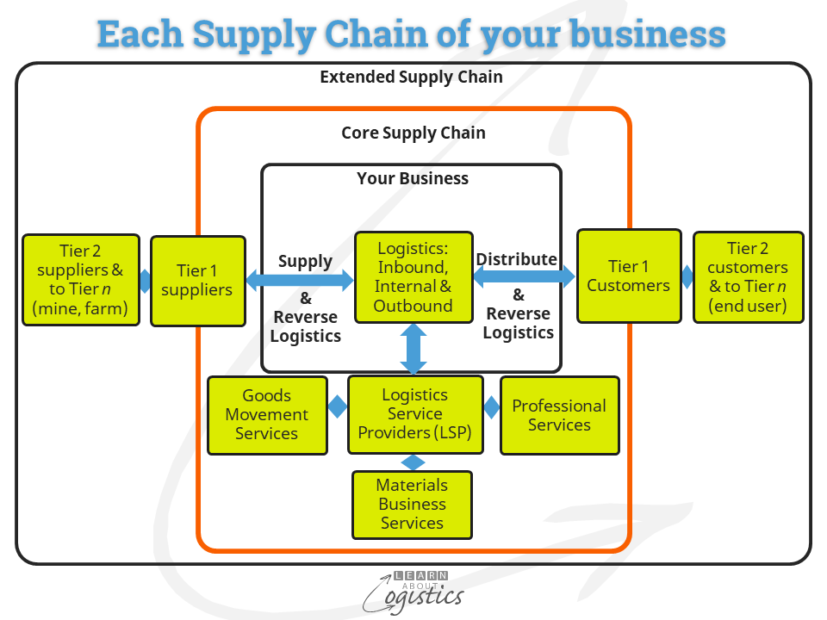

Each Supply Chain has two parts – the Core and Extended, shown in the diagram below.

- Core Supply Chains are from Tier 1 suppliers, through your organisation to Tier 1 customers. It comprises the flows of items, money, transactions and information, facilitated by the Procurement, Operations Planning and Logistics functions

- Extended Supply Chains are the flows of items, money, transactions and information from your Tier 1 suppliers and customers to Tier 2 and beyond

The term ‘Supply Chain Management’ is regularly used, but what is actually being managed? Within your organisation, the Core supply chains have plans, schedules and associated IT systems that can be managed. The above diagram shows that Tier 1 suppliers and customers are only partly within the Core. They are independent of your business and so contract with other organisations (customers and suppliers); these are either not known to you, nor fully understood for the effects their actions may have on your business. So, only your relationships with Tier 1 suppliers and customers can be managed.

The Extended supply chains become complex as each supplier and customer (and their suppliers and customers) throughout your supply chains has their own supply chains. This becomes your organisation’s Supply Chains Network, for which the Learn About Logistics definition is ‘the multiple supply chains that comprise an organisation’s core and extended network of independent, but connected, suppliers and customers.

A Supply Chain Network is a system which contains three elements:

- Nodes – each location that conducts activities concerning items or money. Identify the ownership and control of critical Nodes

- Variables – changes to the physical or financial values at a Node

- Links – transport movements of items between Nodes. Identify the ownership and control of critical Links

- Flows – the transfer of items, money, transaction data and information between Nodes and Links along each supply chain

From these elements, the objective of supply chains is established. The Learn About Logistics definition is: ‘to promote the effective flows of items, money, transactions and information between supplier and customer enterprises, through ‘activity nodes’ and ‘movement links’ at each stage of the core and extended supply chains, to provide value for end users at the lowest total cost’.

The Supply Chain group

To achieve the objective of your organisation’s supply chains requires functions that have responsibility for parts of the supply chains to work co-operatively. The three essential functions are Procurement, Operation Planning and Logistics. In addition to the management of their respective function, a role of Supply Chain professionals to understand how the current and potential Supply Chains Network operate. This knowledge is gained through gathering and analysing data and information for Supply Markets Intelligence and from the three elements of supply chains; especially concerned with inventory and capacity.

Procurement is ‘the processes by which an organisation understands its supply markets, manages relationships with current and potential suppliers and contracts with suppliers to obtain goods and services required to fulfil the ongoing needs of the organisation in a timely manner and at lowest total cost‘.

The role of Operations Planning is ‘to co-ordinate processes in the Core supply chains, to ensure Availability of the required items and satisfy customer demands‘. In the book The Goal by Goldratt & Cox (1984), it was stated that “What you do takes time and costs money. Time is a competitive measure. The more time it takes, the more it costs. Inventory is the shadow of time.”

The objective of Logistics is ‘to satisfy customer needs by providing Availability of goods and services, through the time-related positioning of internal and external resources, at the lowest total cost’. Availability comprises:

- Physical Availability (place, time and quantity)

- Operational and Infrastructure Availability (Operations Support – planning the maintainability and supportability of equipment and facilities)

How well Availability is provided will be influenced by the attributes that your business emphasises – speed, quality of the process, flexibility, dependability or cost. These attributes are, in turn, influenced by location decisions for adding value and holding inventory based on:

- the ‘volume to weight’ and ‘value to weight’ ratios of items

- inventory ‘form and function’ location decisions

- lead times and

- security requirements of items

In the changing environment for supply chains, focusing on functional performance and improvement is not the path to customer satisfaction and effective supply chains. Instead, the functions operating within the ‘supply chain group’, need an umbrella vision under which they can work together and that can be Availability.

Measurement of Supply Chains

A challenge for the ‘supply chain group’ is that the concept of supply chains cuts across the functional structures in an organisation. And people in their functions have a functional view of how things are done – if they concentrate on achieving their function’s performance objectives, then (mistakenly) the supply chains are expected to also perform.

Rather than trying to optimise individual functions, view your Supply Chains Network as a system. This requires a change of mindset; but the adaptability and performance of your supply chains will depend on how well people can work together within the system. Unfortunately, there is a (normal) reluctance to change, even by senior management.

To emphasise the approach of ‘working together in a Supply Chains Network’, performance measures are required for which the supply chain functions share responsibility. The measure of Availability is the calculated capability of an organisation to deliver items and associated services:

- In Full, On Time with Accuracy (DIFOTA), to meet customer requirements, based on an effective

- Sales & Operations Plan (S&OP), with

- inventory turns in the top quartile for the industry

Financial measures for the supply chains group (download Supply Chains Operating Performance) are;

- Supply Chains Working Capital

- Cash to Cash cycle time

- Supply Chains Value Added (VA)

- Supply Chains Return on Invested Capital (SC-ROIC)

Future disruptions caused by climate change, pandemics and disasters will increase, requiring changes to how supply chains are structured and operate. This blogpost provides an explanation of supply chains – using a common base allows rational discussions concerning the future structure and operations of your organisation’s supply chains.