‘Normal’ is not on the agenda

The disruptions to supply chains over the past two years will take at least another twelve months to correct. The rapid increase in cases associated with the latest COVID variant shows that the virus has not finished. And supply chain disruptions influenced by the pandemic could continue; some of them an unexpected surprise.

Suppliers of components (intermediate goods) are aware that the current high demands from customers will fade as consumer demand slows; with demand and supply hopefully becoming more balanced over the next two years. Also, suppliers could be reluctant to invest in new facilities, considering other influences:

- China production expansion, which kept prices of goods low for the past 20 years, has mostly run its course. This may affect sources of supply

- Ocean container sector continues to consolidate. The top five shipping companies currently account for about 65 percent of container capacity; this could be about 80 percent by 2025, which may affect port call schedules

- Businesses in developed countries are experiencing demographic-driven labour shortages, wage increases, higher costs for intermediate products and for capital expenditures e.g. warehouse properties

- Residential B2C deliveries have capacity constraints in some countries, leading to increased transport surcharges for businesses providing ‘free’ delivery. This service may be charged or restricted in the future

- Businesses have raised prices – not all of them justified. Profit margins for the largest US based companies are at their highest

- Geopolitical forces have visibility that can change relationships between countries

- Climate change induced changes that may affect supply chains

Experiences over the past two years have shown that cost optimization approaches are no longer sufficient conditions for products to be available in the ‘rights’ – quantity, place and time:

- outsourcing functions;

- contract manufacturing in low-cost countries;

- consolidation of suppliers and

- available production and transport capacity to provide goods ‘just-in-time’

For supply chain professionals, inbound, internal and outbound supply chains are unlikely to operate through the ‘same old way’ in the future.

Thinking about supply chains

Success of a business is usually discussed as competing successfully against other business in end user markets. But, as shown through the COVID19 experiences, supply should be considered before demand. The real key to success in business is the capability to own, control or influence resources through the supply chains. And these resources are best when not easily copied or adapted.

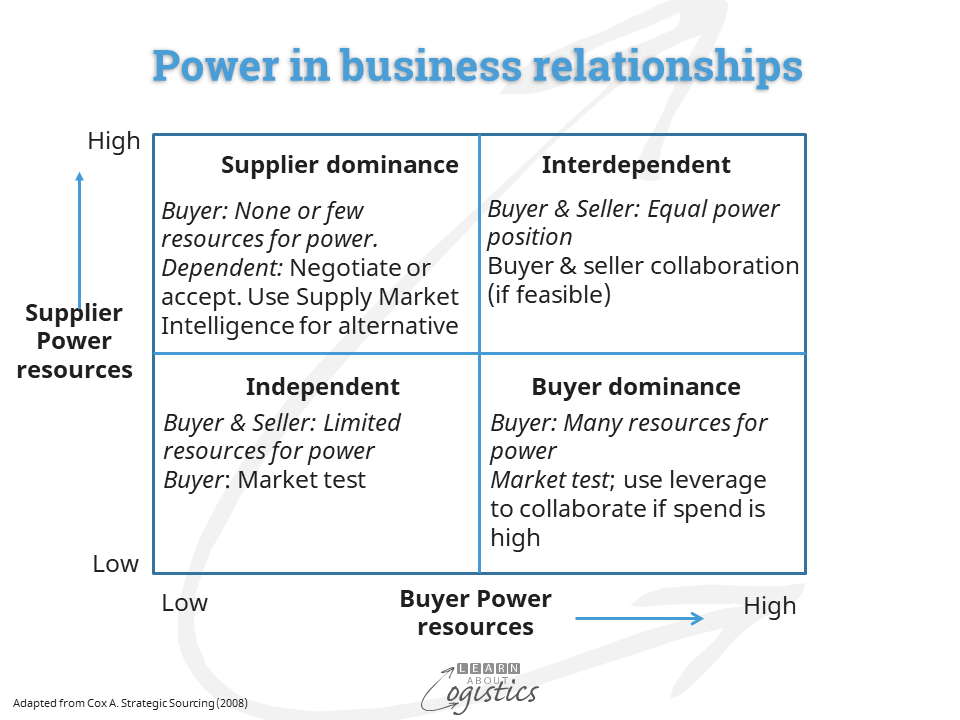

It is therefore essential to develop new ways of thinking about the criticality of assets and resources in your supply chains. The diagram illustrates an approach to identify how Power in business relationships can be used to leverage critical supply chain assets.

Examples of how Power can be used at a supplier to own, control or influence critical assets are::

Availability of an item:

- Licence to operate and supply provided to the supplier by a government

- Spread of customers – supplier reduces their dependency on large and powerful buyers; progressively adopt a policy of low percentage of total sales conducted with any one customer

- Supply for an item that is difficult to obtain – controlled or constrained by the supplier

Capability in the business:

- Specialised knowledge that restricts the number of potential suppliers

- Focused product – incorporate value added services into the product, which cannot be easily duplicated

- R&D investment – regularly provide new products and services that address customer needs

- Technology leadership – hold patents, copyright and intellectual property (IP)

- Reputation and prestige – is known as the ‘best’ supplier for a product or service range

- Systems and processes implemented by the organisation that allow provision of superior customer service

- Potential impact of technological and regulatory changes on current supply chain resources and assets are closely monitored and acted upon

As your organisation’s Supply Chains have unique properties that require specific and appropriate treatment. Understand when it is appropriate to use a particular approach, practice or process; not just copying other companies.

As examples, businesses do not ‘partner’ with suppliers – relationships are governed by commercial contracts in which an agreed behaviour between parties is documented. Nor do businesses exist to ‘delight’ customers. Companies exist to acquire and accumulate value from customers, suppliers, competitors and employees through effective (not ‘cost down’) management – that is, to make a profit. For example, the first objective of Hewlett Packard, when controlled by the founders was: To achieve sufficient profit to finance our company growth and to provide the resources we need to achieve our other corporate objectives

Supply Chains thinking for your organisation

- For a business to grow, it cannot just rely on ‘core competencies’, cost reductions and reducing headcount through outsourcing – you cannot shrink to glory!

- Identify which of the assets and resources in a supply chain are critical, complementary or of residual importance

- Evaluate which existing and future resources in supply chains should be owned, controlled or influenced for value to be gained

- Understand which assets should be pursued in order to control the acquiring and accumulation of value in supply chains

- Add value to your supply chains by using valued people to evaluate the supply chains for new end user markets. Identify how specific supply chain resources can become critical assets, which may provide a permanent or temporary monopoly for the business

- Recognise the importance of material scarcity, monopoly power and leverage of Intellectual Property (IP) in supply chains

- If unable to own or control assets, or to create effective barriers to entry in supply chains, a business will experience a competitive market, based on copying and adapting products and processes

- If competitors are pursuing aggressive competition and products can be easily imitated, then increasing amounts of value in the supply chains are passed to customers and consumers

- In a competitive market, where a business does not have critical supply chain assets, the objective is to seek a relatively superior competence to competitors

Given the difficulty to know what supply chain assets should be acquired, owned, controlled or influenced requires individuals that are willing to take calculated risks from the uncertainties. Does this approach to thinking about supply chains apply to you?

This blogpost is the last for 2021. As it is summer in Australia, the beach calls. The first blogpost for 2022 will be published on Tuesday January 25. Thank you for reading Learn About Logistics and stay safe.