One Plan process for your organisation

Tactical planning that assists the future profitability of a business needs to be a core feature of your organisation. This is whether, under the business environment after COVID, the driver of your business is to be efficient, responsive or agile, as discussed in the previous blogpost.

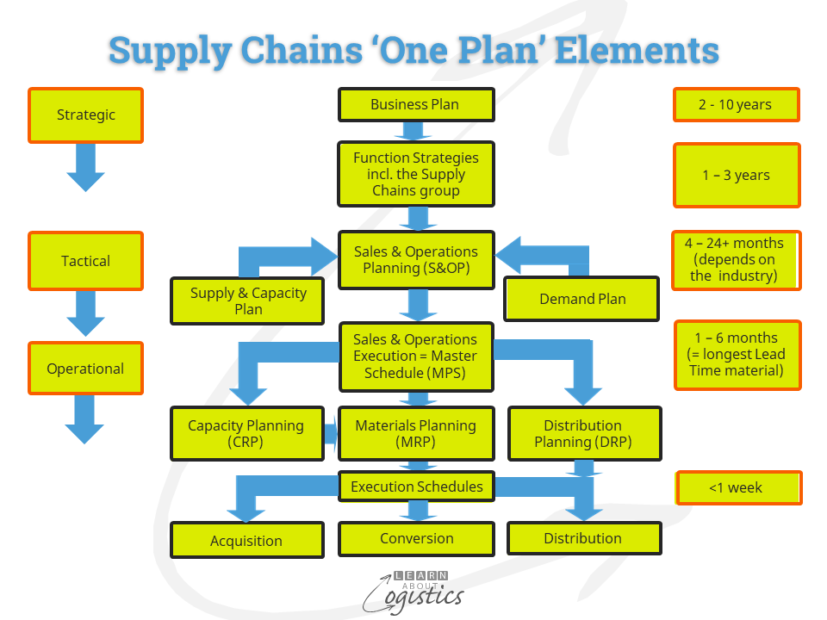

Sales & Operations Planning (S&OP) is the tactical planning part of the process, illustrated in the diagram below as an integral to the totality of planning. It is the heart of your business; positioned between the strategic head and operational veins.

However, it is a process in its own right, that should not be mixed with either strategy or operations. The objective of S&OP is to provide availability of items for delivery, where there are capacity constraints in purchased, leased or owned assets.

Although associated with manufacturing, S&OP can be successfully used in any organisation that requires a structured process for balancing ‘demand driven’ sales with ‘supply supported’ resources (items, people, equipment and suppliers). This can be in sales focussed organisations that outsource all manufacturing and distribution to 3rd parties; those that import products; sell logistics services or need to plan logistics activities such as a loading terminal for commodities or operating a shipping container park.

Having identified what S&OP is, understand what S&OP is not:

- The strategic business plan: S&OP is a structured tactical process for planning over the medium-term (4 -24+ months, depending on the type of business, but typically 18-24 months)

- A budget review: S&OP is based on current inputs concerning demand and supply. Budgets are an annual positioning exercise. S&OP must not be constrained by budgets, but the output from S&OP can be used as an input to budget updates

- A weekly or bi-weekly operations meeting. This is the role of the Sales and Operations Execution process (see diagram above)

Who is involved

To be clear about terminology, the terms:

- ‘Sales’ includes the groups and departments on the demand side of an enterprise. This includes: sales, marketing, product development and demand planning

- ‘Operations’ includes the functions that work to supply products and services for sale. They include: Procurement, Operations Planning and Logistics (the supply chain group); production/operations and technical/engineering

But S&OP is an inclusive planning process, therefore other functions involved in the process are:

- Finance, which evaluates the proposed plans on the basis of cash flow, financial management and profitability. However, S&OP is a planning tool for the organisation, not a finance department budget routine

- HR/Personnel and

- IT

The chairperson for the S&OP Executive meeting is the P&L responsible manager (division, country, site etc.), with the role to have the executive group arrive at an achievable plan. As the focus of individual functions differs, the chairperson must ensure a balance between the opinions, perceived power and status of the disciplines. To facilitate the total S&OP process is a role for the senior planner, who is typically located within Operations Planning.

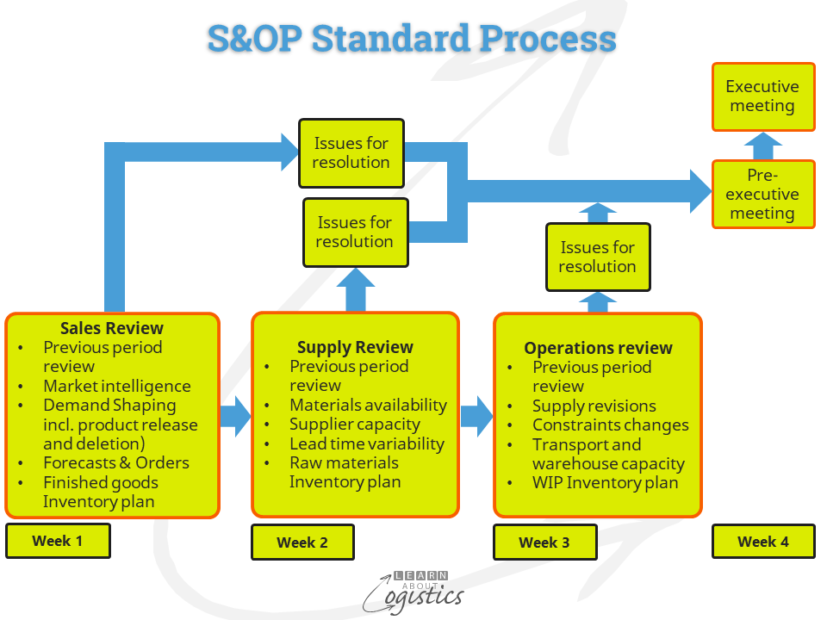

Any process that has a structure, can be accused of being rigid in design and not responsive to evolving economic and business situations. The diagram below illustrates that S&OP has a standard review process prior to the monthly S&OP Executive meeting. However, this is more of a guide, which can be modified to suit individual business requirements.

S&OP is a planning process

S&OP is not part of scheduling product lines, therefore to ensure meetings do not become focused on individual products nor ‘bogged down’ by data, the S&OP process must use aggregated data, based on product ‘families’ and their processes:

- The number of families varies between 5 and 15 (preferably in a range of 6–12)

- ‘Families’ are based on the capacity utilisation at ‘bottleneck’ resources within ‘Operations’. In some circumstances, families may reflect the few brands or models of major customers, such as when supplying to automotive assemblers

- Sales forecasts by product group are linked to the S&OP families. Forecasts are summarised by market segment/territory and SBU/division totals. Within the analysis of product families, allow a sales variance of (say) +/- 5 percent from the weighted forecast

- Inventory for each family at nodes in the supply chain is identified by form and function

- For each product line, structure the Bill of Materials (BOM) within the ERP system to ‘roll-up’ into their ‘family’

- ‘Operations’ capacities are expressed as a standard unit of measure e.g. tonnes, shippers (the carton size shipped to customers), litres, hours, pallets etc.

- S&OP reviews are by product family, using the standard unit of measure. This provides a consistent communication base across all functions and entities

- The S&OP by each ‘family’ becomes an input to the Sales & Operation Execution (S&OE) process, that commences with the Master Schedule (or similar term) in the ERP system (refer to the first diagram above)

- The ideal situation to increase certainty in supply chains, is for an organisation’s Master Schedule to become an input to the suppliers’ S&OP process and those suppliers do the same for their suppliers

Using a medium-term planning view, using aggregate data, assists the management group to:

- discuss and agree on the output capabilities of the organisation (based on known constraints);

- assess the value of new product releases and market expansion and

- recognise potential risks, for both output and finances

S&OP is not a software driven process. However, to be effective, the S&OP process requires accurate and timely input data, with the means to use the data in simulations and scenario building. Very quickly, it will be evident that IT assistance beyond spreadsheets and emails is required.

As many S&OP applications are sold by US based firms and few appear to be cloud based, there may be limited choice in particular countries. However, do not allow that to delay implementation; recognise the limitations of spreadsheets and concentrate on people and process, which Supply Chain Insights has estimated as 90 percent of the challenge in making your S&OP effective.