Selling technology solutions

A LAL blogpost written one year ago discussed the potential uncertainties of developing and using artificial intelligence (AI) within your supply chains. As the rate of promotional activities has not slowed, think about the steps to take before AI.

In competitive technology situations, there are products to sell and concepts for potential buyers to get excited about. This requires promotion by marketing departments, but it also can include surveys and reports, provided by consultants. These can help to improve credibility with potential clients, through endorsement of a technology and its potential.

Much promotion for technology products uses the ‘fear, uncertainty and doubt’ (FUD) sales technique, to enhance the ‘fear of missing out’ (FOMO), among potential customers and clients. For AI, the FUD is that your competitors will have AI before you, therefore your business will lose.

This was the approach used many years ago to sell MRP and ERP systems. However, for all the claims of big savings and return on investment (ROI), studies have shown that installing an ERP system did not lead to improved profitability or ROI. The lack of expected results “lies not with the technologies themselves, but with a lack of effective implementation planning by companies” stated one report. There may have been improved planning decisions, but these are difficult to measure.

The Gartner Hype Cycle for Supply Chains report in 2020 noted that AI was at the first of five stages in its hype cycle (i.e. the Innovation Trigger). By 2024, has AI reached Stage 2 – the Peak of Inflated Expectations? There are a further three stages in the cycle before AI could achieve general acceptance. Gartner expects this to be around 2030, when climate change is likely to be grabbing all the headlines.

As an example of inflated expectations, the 2024 MHI report notes that “In 2019, 79 percent of survey respondents believed that AI would be a core competency by the end of 2022. Yet, according to the 2024 survey, only 27 percent of participating supply chain organizations are currently using AI in any form. of these, the majority could be using AI built into purchased software applications, where the customer had no control over the design of algorithms.

The main challenge when selecting and implementing software technologies is not technical. Instead, it is understanding your organisation’s supply chain challenges and capabilities and how the software application or tool will address them. The skill required of supply chain professionals is therefore to ask questions concerning how a particular software can respond to the challenges in your complex supply chains. So, when hearing or reading about the benefits of AI, evaluate how the claims apply to your business by asking ‘why’ five times about each benefit being promoted.

Simplify Supply Chains Planning

An element of the FUD sales approach is to convince prospective buyers that AI can solve complex problems, which can lead to inflated expectations. But, if AI is purchased to solve complexities, is there also a risk of more complexity? Instead, with the thorough job done of understanding your organisation’s challenges and capabilities, why not work to simplify the planning of your organisation’s supply chains and scheduling of Operations. Following simplification, you can better consider if and where AI can be of benefit.

To improve the functioning of your Supply Chains group, focus on structure, data, workflow, processes and people.

Structure: The form that information and data is gathered and presented through its flow. The core document is the organisation’s Supply Chains Network Design Map. This identifies the interactions between Nodes and Links in the Network, including instances of Power and Dependency in relationships. The Map provides information for the Demand, Sourcing, Inventory and Logistics Plans.

Data: The emphasis must be data that is clean, accurate, reliable and timely. Implement a process to remove the ROT of ‘redundant, obsolete and trivial’. Input data which is not controlled by Operations Planning is a continuing challenge, including data that is missing, not considered, inaccurate and mismatched from various sources. Forty years ago, as a vital part of implementing MRP/ERP systems, APICS presented a course on managing data accuracy, including a checklist and audit process. The need is no less today, but current articles indicate that the situation has not improved.

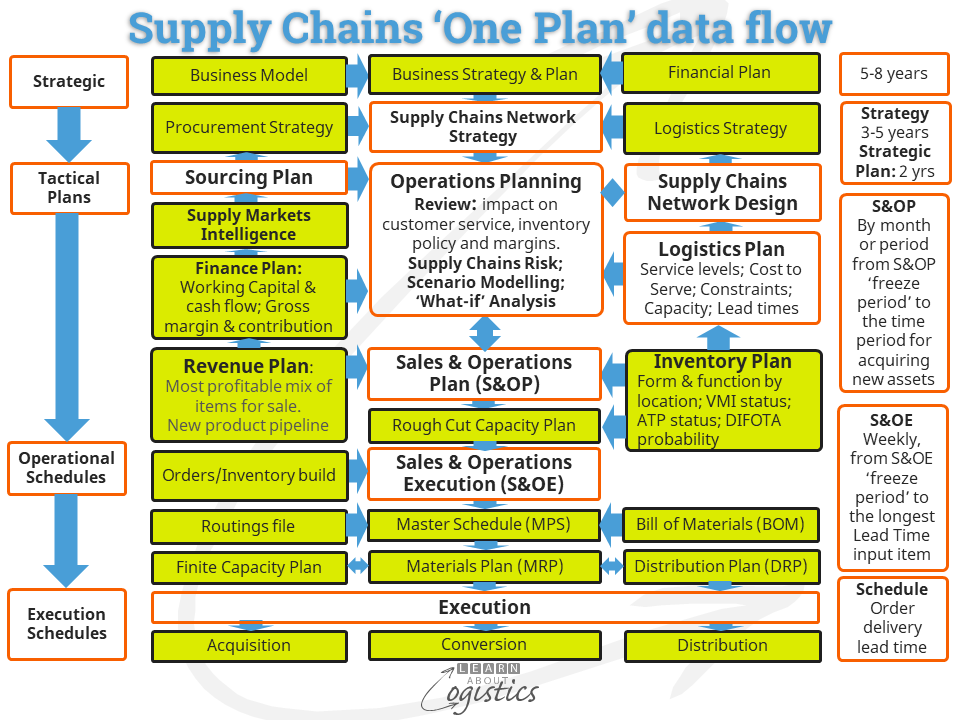

Workflow: The Supply Chains ‘One Plan’ Data Flow diagram below illustrates how the data and information flows through a business. Without this Network view of an organisation’s supply chains, there can be a lack of alignment between functions that interact with the Supply Chains group. There is also the potential for less visibility across the complex network, which can be geographically dispersed.

Processes: ‘The way we do things’. To simplify planning and scheduling, there are initiatives that can be taken:

- Implement segmentation of customers, suppliers and inventory to better balance needs and responses

- Implement Available to Promise process between Operations Planning and Customer Service

- Forecasts to use the probability of a level of sales, indicating optimistic and pessimistic volumes. This translates to Operations planned within a range of probability, which enables better acquisition of items.

- Recognise that increased SKUs and a high asset utilisation objective can result in more lumpy demand and potentially longer lead times

- Consider Postponement as a planning action for more responsive/agile supply chains

- Recognise that high Variability in activities provides increased uncertainty, therefore a ‘Just in Case’ approach to planning

- Identify the organisation’s supply chains and manage inventory using Coefficient of Variability (CoV)

- Identify where buffers of inventory and capacity can be held through the supply chains

- Work on a program for standardisation of materials, components and parts

- Identify where there is a lack of interface between application processes e.g. Transport Management System (TMS) and Distribution Requirements Planning (DRP)

People: Collaboration is the word that should govern supply chain relationships. However, functional organisation structures hinder this, because ‘we behave how we are measured’ and collaboration does not have numbers attached. In addition, people in the Supply Chains group require a common understanding of definitions and planning logic in supply chains.

These supply chain planning challenges influence how planning applications are structured and implemented. This discussion has illustrated the many activities required to improve your organisation’s supply chains before entertaining ideas of implementing AI