S&OP in your business.

Planning sits at the heart of your Supply Chains and is one of the three objective measures of the Aim, discussed in the blog Developing a strategy to change your supply chains. The blog of June 20 discussed the objective measure of DIFOTA – delivery in full, on time, with accuracy. This blog introduces the planning process to provide Availability, which is Sales & Operations Planning (S&OP).

S&OP is a rolling monthly process that determines whether future demands can be met with the expected supply in such a way that customer service levels and financial objectives are met. The key word in S&OP is Planning; to provide a view into the future, so that an organisation can:

- prevent issues from becoming potential bigger problems

- have time to address potential problems and

- take proactive, corrective action to address potential problems

To be effective, the S&OP process needs a planning horizon into the future that provides adequate time to make the required changes. Typically, this will be in the range of 12 – 24 months, but will differ depending on the specific circumstances of an enterprise. So the process is not ‘bogged down’ by numbers, the process relies on aggregated data, based on product ‘families’ and their processes.

S&OP as a business planning process implies its use by organisations that make and distribute products. However, the principles and process of S&OP are applicable to any business through a supply chain, including those that import products, contract out their operations or sell logistics services. It is also applicable for planning activities such as a loading terminal for commodities or a shipping container park.

S&OP entered the language of supply chains more than thirty years ago, yet for all its obvious benefits, has failed to gain traction in many organisations. Even though S&OP is a process to address planning for the whole business, senior management are generally unaware of its value because:

- business courses at universities and colleges rarely include the study of S&OP

- consultants have tended to discuss S&OP as a supply chain process, therefore management expect executives associated with supply chains to champion the adoption of S&OP. This requires that executives understand the process and therefore can sell the benefits to the P&L responsible manager – the site manager, general manager, country manager or region manager

- consultants have attempted to ‘own’ the process by renaming S&OP as ‘Integrated Business Planning’; ‘Sales, Operations and Inventory Planning’ and ‘Sales and Inventory Optimisation Planning’. However, the underlying principles and processes do not change. This adds some confusion concerning what is S&OP

- Software suppliers have not invested sufficiently in the development of S&OP applications. The market is seen to be limited, because of the previous bullet points and that the process is not software driven. However, while not software driven, S&OP is software assisted and higher levels of adoption would increase demand for applications

Towards internal collaboration

As a process, S&OP is not difficult to follow (this will be discussed in the next blog) – the challenge is to make it happen; because implementation will commence the journey towards internal collaboration. The journey begins with improvements to co-operation and co-ordination between functions, which should start to appear about six months into the implementation, but to achieve real collaboration may take up to three years, to become the ‘way we operate’. The challenge is that in these days of ‘instant’ improvement, are you and your colleagues willing to work at improving a process (and results) for this length of time?

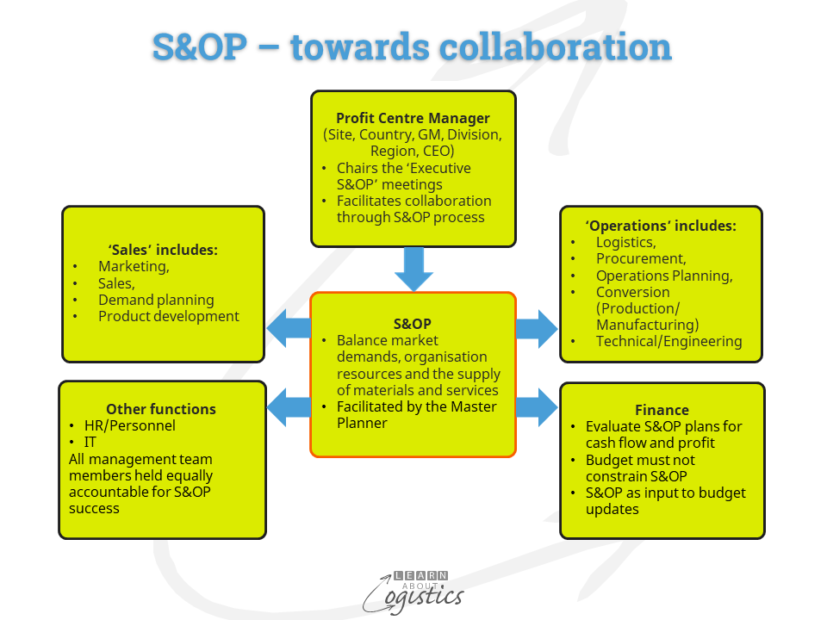

Working towards collaboration is inherent in the terminology. As shown in the diagram, ‘Sales’ includes all departments or groups working in the demand side of an enterprise. ‘Operations’ includes the functions that work to supply products and services for sale. In addition are functions which are also part of the S&OP process:

- Finance, which has a core role to evaluate the proposed plans, considering cash flow and profitability. But, S&OP is a business planning technique, not a finance department budget activity. However, the output from S&OP should be a part of the monthly update to the budget

- HR/Personnel and

- IT

The P&L responsible manager is a critical element within S&OP. Their buy-in to implement S&OP includes gaining support of the management group. This requires addressing the likely lack of understanding about S&OP and its role in the business, plus addressing issues concerned with perceived power and status by managers in the organisation. In the early days of implementation, the P&L manager needs to ensure a balance between ‘sales’ and ‘operations’ and other functions as they learn about what collaboration entails.

While functions have competing priorities, these must become secondary to achieving the S&OP output plan, which should be viewed as the ‘hub of the business’. To achieve this objective, the senior management team are held equally responsible for the success of S&OP, forcing all managers and their staff to jointly resolve problems and improve the S&OP process. Hopefully, this should reduce ‘finger pointing’, whereby problems are other people’s fault, but not mine!

To be successful with S&OP may require a change in attitudes at all levels of management about working in teams and therefore how ‘success’ is measured. It takes time to change the culture in an organisation – revised processes are implemented, new performance measurements (metrics) developed, used and understood and IT applications proposed, tested, purchased and implemented. When internal collaboration has been achieved, it can be replicated with selected customers and suppliers. S&OP is not a ‘quickie’ improvement initiative, but a long term project.