Definition or measure of achievement.

Agile, like Lean before it, is a concept that has existed for decades. It contains much merit, but commentators have tended to promote both concepts as vital to business survival, have minimal ‘steps to success’ and by themselves will solve an organisation’s problems. So, like the introduction of new technologies, we go through the “Hype Cycle” of inflated expectations followed by disillusionment.

Elements of lean and agile concepts have been implemented within production operations, but few published examples (outside of automotive and electronics) illustrate implementation through an organisation’s ‘core’ supply chains (from tier 1 suppliers to tier 1 customers) and I am not aware of any in a wider supply network.

Of more importance than a definition of Agile is a measure of achievement and one that appeals is from the SCOR Framework. Mixing the metrics for flexibility and adaptability provides a measure of Availability (the role of Logistics): “To achieve an unplanned but sustained minimum 20 percent increase or decrease in produced and delivered quantities (spikes, not seasonal) in 30 days at zero cost and without back-orders, cost penalties or inventory increase”.

This metric could be applicable for organisations (and their tier 1 and 2 suppliers) providing goods to the retail Fast Moving Consumer Goods and Consumer Packaged Goods (controlled through ‘use-by’ dates) sectors. Here, expectations of customers appear to be that additional and deleted SKUs will provide a high product mix of lower volume products; these must share limited production assets. Also that changes in volumes and reduction in lead times are an acceptable condition of business, which results in a more volatile demand pattern. So, using the metric as a basis of providing Availability, how should a business in these circumstances respond?

Three steps in response

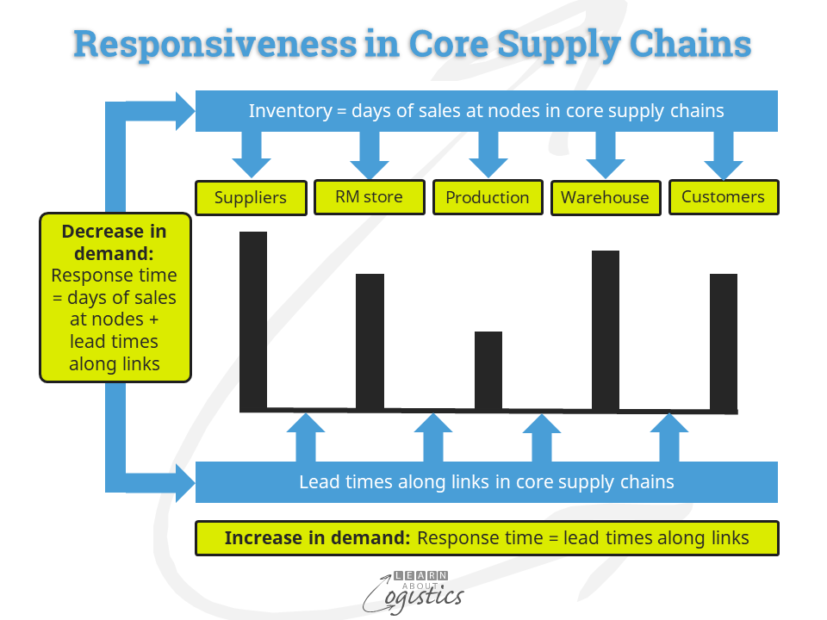

The first step is to measure the scope of the challenge. Within your organisation’s Supply Network Design, incorporate the diagram below, which identifies the responsiveness of ‘core’ supply chains, through identifying the time equivalent of inventory at nodes and the lead times through links. A similar diagram for the ‘extended’ supply chains can be done following success in the ‘core’. The figures enable the calculation of days required to address an increase or decrease in demand. The total days to respond will likely be higher than expected, but the diagram will identify where the ‘quick wins’ for reduction in inventory and lead times exist.

The majority of businesses operating in the FMCG and CPG sectors are ‘make to stock’ (MTS) that build inventory to satisfy forecasts of sales. However, as shown in the diagram, inventory reduces the flexibility an organisation in responding to market changes. To substantially reduce inventory requires that products are held in inventory at lower ‘value-added’ levels, but can be finished quickly to meet customer needs. This second step is the process called Postponement.

Form Postponement or Delayed Configuration is based on the concept of product lines that have a common platform of modules, components and materials. The product customisation or final assembly occurs when the customer requirement and/or market destination is known. The types of product that can incorporate Postponement are Make to Order (MTO) and Assemble to order (ATO).

MTO provides a design and manufacture service for options applied to a base product – it is the adaptation of pre-designed products. The base item could be produced in advance of orders, depending on:

- the expected (by customers) delivery lead time for the finished item

- the variability of demand for the base item

- the inventory value of base item

- the range and complexity of options

ATO applies to discrete or ‘mix and stir’ (non-discrete process) materials assembled to order. The specific orders for catalogue or recipe products are received from customers or the sales department. An ATO business will make or buy materials, components, sub-assemblies, packaging and options to:

- Immediately assemble the items into finished goods and deliver, using a ‘just in time’/lean flow manufacturing process

- Assemble and deliver both directly purchased or previously produced and stocked discrete sub-assemblies or ‘mix and stir’ process ingredients

Moving from a MTS to a MTO or ATO model will affect all elements of a business and therefore will not be accepted by all who could benefit. Postponement is more applicable in businesses that are less capital intensive and more reliant on their human capital. Also, as a business model, Postponement does not have an automatic lower cost structure; it requires more changes to be successful.

The third step is implementation of Sales & Operations Planning (S&OP); the structure for bringing together the Demand and Supply Plans. With good intentions, the senior executives and the management team can be working from one plan in about six months. However, to get from success for the initial stage to acceptance that S&OP is the ‘way we do business’ can take up to three years. It takes times to change the culture in an organisation.

In this time period, there is learning for all affected staff, both current and replacement. Revised processes are implemented. Data collection and cleaning to provide improved Analytics. New performance measurements (metrics) developed, used and understood and IT applications proposed, tested, purchased and implemented.

Meaningful measures of performance that provide a basis for improvement is a more valuable approach than just picking on a new term or technology. The challenge is structuring the measurement(s) that best reflect the market requirement and operational response.