A different structure

When will the next major disruption to your organisation’s supply chains occur? And what will be the cause – climate, conflict, pandemic, financial? For each of these questions there is not an answer, although many predictions. But if supply chain professionals wait until a disruption occurs before responding, then it may be too late for the business.

Responses to surveys show that few businesses have considered, let alone implemented, a comprehensive approach to the challenges of the next major disruption. Is this because senior management is generally unwilling to give away the centralisation of power and what they consider as control?

But with global supply chains, disruptions will be defined by their interplay with other disruptions and consequences that are unknown. Reacting to each separate disruption through central control will be less of an option. Instead, a more decentralised and flexible response mechanism is required. Having supply chains and workplaces enabled for decentralised decisions, with access to current data and risk and scenario analysis outcomes.

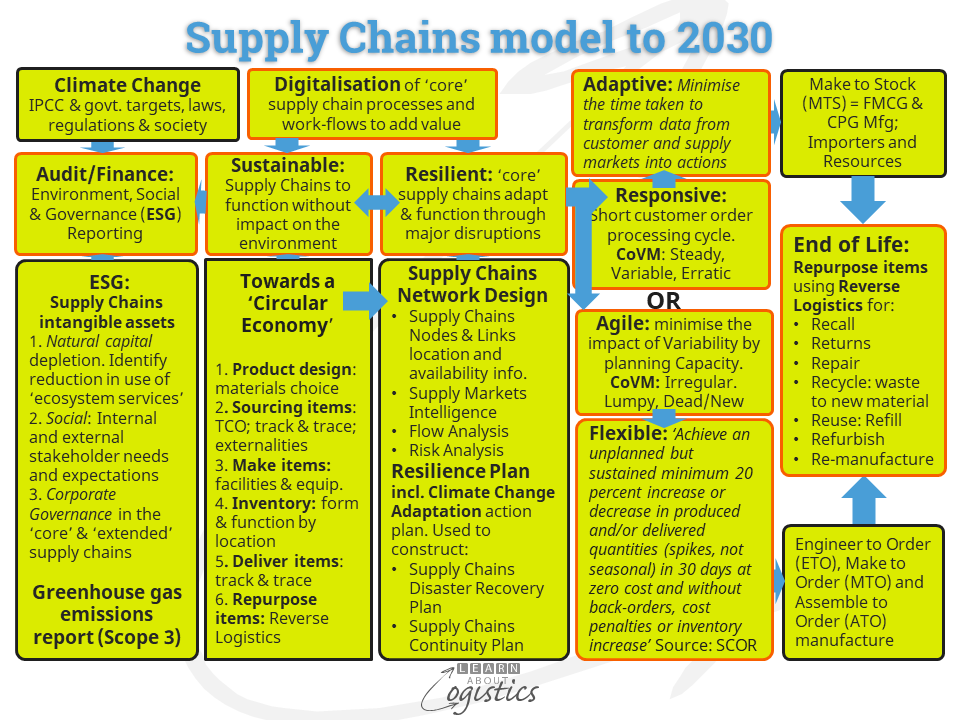

The diagram illustrates the LAL model for supply chains to 2030. For businesses considering something similar, a minimum period of about five years can be expected for implementation, but only if the same senior management team remain to champion the successes. After 2030, as Climate Change gathers momentum, the model is unknown, but at least organisations will be better prepared.

Design the Resilience Plan

The centre of the diagram shows that ‘Sustainable’ and ‘Resilient’ are a key requirement of businesses into the future. Across a business, resilience must be implemented to include: the business model, finance, supply chains, operations, technology, and the organisation. However, this blogpost concerns how the ‘Core’ supply chains (between a business and its Tier 1 suppliers and customers) can adapt and function through major disruptions. Ideally, this need should extend through the supply chains to the lower tier suppliers and customers, but that is unlikely to happen for most businesses.

To have resilient supply chains, the diagram highlights the Supply Chains Network Design (also called the Supply Chains Map). This is the depositary of all information concerning the Nodes and Links of inbound and outbound supply chains. Included is a risk analysis of each Node and Link supply, which is accessed by the Resilience Plan.

The Supply Chains Resilience Plan can be based on achieving risk avoidance, mainly through building buffers of inventory or capacity at the Order Decoupling Points between demand and supply. Because major disruptions can be both multiple and cumulative, a risk avoidance approach through prevention may not be sufficient. Instead, the approach should be to ‘prepare for disruptive events’, considering the potential scope and interconnectedness of disruptions.

This Plan is used as the basis to construct the Supply Chains Disaster Recovery Plan and the Supply Chains Continuity Plan. These identify the capability and processes required for the immediate response and short-term actions required to recover from and then continue supply chain operations following a major disruption. When the business is able to continue operating, a review will highlight deficiencies and opportunities for improvement in the plans. However, these plans address the essentials for recovery from a disruption; they are not a business growth project – that belongs to the next section in the diagram.

Design of the Supply Chains Resilience Plan includes several elements which may add to costs for the business:

- Map aspects of Climate Change (e.g. heat, storms) and geopolitical threats in both sales and supply markets. This identifies the ‘where’ of possible disruptions and potential impacts on the supply chains

- Develop increasingly disruptive scenarios across a wider circle from the previous step

- To establish the ‘what’ and ‘when’ of disruptions, identify the data and speed of access required

- Identify the ‘reactive workflow’ required when a disruption occurs. This includes detecting disruptions, predicting the impact, and confirming the supply situation for critical inputs. Assess the ability of the Supply Chains group to collaborate in real-time with Tier 1 suppliers and potentially across all tiers. Asses the accuracy of data and speed of data transfer.

- Use the specific Segmentation approach to identify the effect of a disruption for customers, suppliers and products

- Scope supply chains resilience requirements from the perspective of impacts on the business and demand and supply markets. Where required, redesign the planning and scheduling processes and Tier 1 supplier relationships

- Identify the Visibility and communication requirements across supplier and customer tiers

- Measure resilience requirement based on a ‘sales at risk’ approach

- Identify resilience capabilities in the supply chains and Supply Chains group (Procurement, Operations Planning and Logistics)

- Scope authority and responsibility for resilience actions within the Supply Chains group

- Define a portfolio of resilience investments e.g.:

- ‘Just-in-Case’ inventory holding of critical inbound items and outbound products; production design for Postponement where possible

- Expand the supply base, including alternative supply regions and trade routes;

- Redesign the operating model concerning location; vertical integration; decentralisation and outsourcing/insourcing decisions

To cover for unknown eventualities, businesses need to plan for cumulative situations. That is, the initial impact of the disruption(s), then, as found through the COVID pandemic, the second and third level of effects. These could be a delayed effect which quickly gathers momentum or an effect which slowly gathers momentum, until a tipping point is reached, requiring drastic action.

From Resilient to Responsive or Agile

The work to build resilient supply chains addresses the immediate and short-term horizon for considering the response by the Supply Chains group of your organisation to a major disruption. But what about the longer term? Here, the business model is the driver, which identifies how the business intends its customers to be serviced.

A business can be broadly structured as supplying customers from an inventory of finished goods or expecting customers to contact with the question “how much will the order cost and when will I get it”? The first requires a business to be Responsive in supplying the order, through having a short order processing cycle. The second requires a business to be Agile through planning of capacity.

But it is through Segmentation that the business can be structured to respond to customer demands with service levels that meet their needs and are profitable. This will be discussed in the next blogpost.