Procurement in supply chains.

Procurement is still evolving from basic buying – getting the lowest price for items, to being an integral part of an organisation’s supply chains structure. This structure includes the core operational functions of: Procurement, Operations Planning and Logistics; however, they can have many titles, depending on the organisation and location.

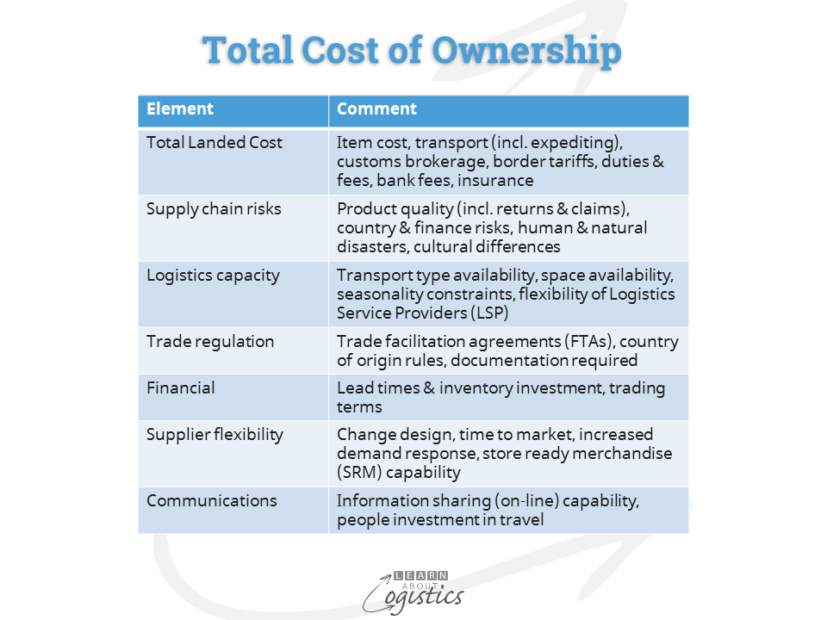

Within your supply network, the objective of Procurement should be to achieve the lowest ‘total cost of ownership’ (TCO) for the business. This takes account of all the cost drivers in the supply chains, which should be a major consideration when developing sourcing strategies. For each cost element, there are cost drivers, with the most common used in TCO calculations identified in the Comment column:

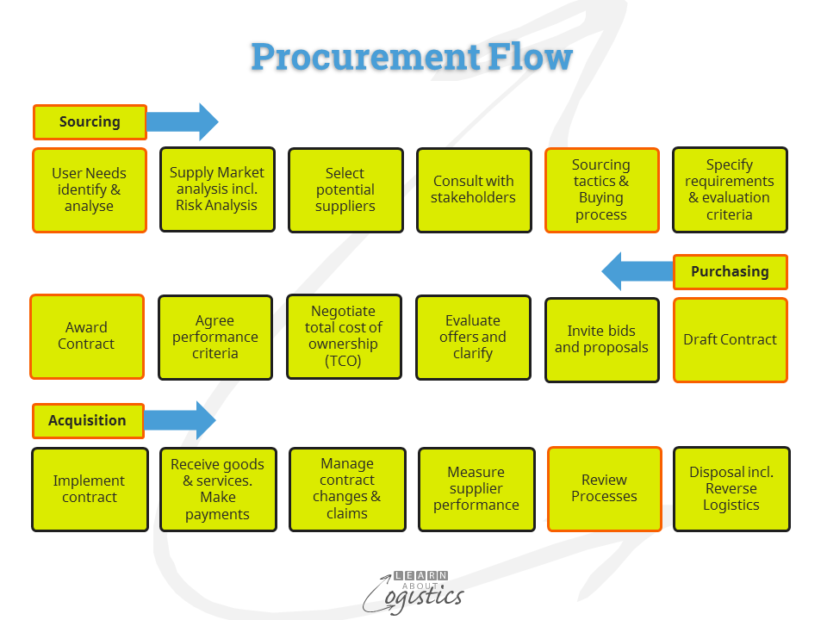

The ongoing sustainability (viability) of your organisation can be impacted by the effectiveness of Procurement because of its governance role. That is, defining requirements/scope of work (SOW), agreements, contracts and purchase orders. So, an additional skill set that is gaining attention as part of TCO, is applying sustainability principles throughout the Procurement flow. The Procurement Flow diagram consists of stages through the buying process, from ‘identifying a business need’ to ‘disposal after use’, with the red blocks indicating the stages likely for review and approval.

Sourcing becomes strategic

Sourcing is a key success factor for any organisation that buys goods and services from suppliers. The objective of strategic sourcing is to pull together the capabilities of the various supply markets to obtain a lower TCO. The elements of strategic Sourcing are:

- User needs: Working with user groups to identify and analyse the actual needs for new physical or service items. Also, where there is a change of corporate policy for an established item (i.e. change of packaging materials to bio-degradable)

- Supply Market: understand the overall market and its economic drivers. Use Risk Analysis to define uncertainties surrounding a supply market. To evaluate current and potential suppliers, develop a standardised supplier capability statement

- Sourcing tactics and the Buying process: Consider off-shoring, near-shoring or on-shoring; exploit inter-dependencies in the market; extent of using eProcurement or eSourcing applications

- Requirements and evaluation criteria: Use of Functional (technical) specifications or Performance (outcomes) requirements

Through these elements, a sustainability focus can be incorporated into the overall Procurement business decisions. To assist with company initiatives, the International Standards Organisation (ISO) has published the International Standard for Sustainable Procurement (ISO 20400: 2017). Because the Standard is a guidance document (not a compliance document), the assortment of good practices can be implemented in any type and size of organisation, to suit its circumstances.

The Standard takes an holistic view of sustainability, considering all aspects of the relationship between an organisations and its suppliers. So, while addressing that purchased products and services are sustainable, it recognises this incorporates many social and economic issues at suppliers and within their wider communities.

Good practices from the Standard can be incorporated into the Sourcing elements, which then flow into the operational elements of Purchasing and Acquisition. Examples of the practices identified in the Standard are:

Internal within Procurement and the organisation: fair operating practices; consumer issues, governance issues; risk management processes; accountability, transparency, ethical behaviour; cultural differences, different definitions and regulations at supplier countries; due diligence processes; avoiding complicity and exercising influence

External at suppliers: labour issues (including discrimination and gender inequality) and human rights; community involvement and development; reporting grievance issues and disputes; accountability; transparency; ethical behaviour

The overview of the Standard proposes that, prior to an organisation incorporating sustainability elements into its Procurement Flow, four actions are required :

- Review your ‘buying culture’: internal and external relations, the extent of analysis undertaken and the strategic value of Procurement to the organisation

- Know your supply chains financial value to the organisation: the percentage of revenue used to pay suppliers and the TCO

- Think strategically: the risks and opportunities of working more closely with your main suppliers – across the whole life cycle

- Get buy-in from top management: benefits are sold to key decision makers and influencers; the opportunities and possible consequences of implementing sustainable procurement into your organisation

These actions read well and are necessary, but to happen they require Procurement to already have credibility and be viewed as a strategic part of the business. For Procurement to be viewed as strategic, it must have four incorporated elements in its structure:

- Participate in the business strategy review – identify business needs and the capacity and capability to engage with external sources

- Lead the category and spend reviews of the business, to understand where the organisation’s income is spent, within categories of items

- Develop and implement the Procurement Strategy

- Manage the Sourcing process and have corporate responsibility for the Purchasing, Acquisition and Disposal flow processes (which may be physically performed by operating groups within the organisation)

This range of responsibilities requires a team of professionals, able to develop and sell proposals; interact across all areas of the organisation and represent the organisation to external parties. The ISO document will assist Procurement groups that are recognised as strategic to the organisation, but for many businesses, there is work to be done implementing the four elements to make Procurement strategic.