Planning and Uncertainty

In response to supply chain uncertainties, articles and podcasts have advised businesses about actions to take. Popular advice is to expand the network of suppliers, source items from suppliers located geographically closer and accelerate the implementation of automation. An action that is rarely mentioned is to improve the planning and scheduling process within a business.

Planning at the tactical level has the greatest value for a business, because it requires collaboration between the affected parties. To be successful concerning the deployment of assets, they must have agreed definitions and use the same data to provide a range of outcomes against which decisions are made. But as the horizon lengthens, the outlook becomes more uncertain, so outcomes are indicative and not required to be ‘correct’, but that does not make Planning less important.

Planning is thinking into the future regarding the activities required to achieve a desired goal, which is to have achievable outcomes to serve customers. That is, to be Effective.

Effective then Efficient Operations

In the previous blogpost, the term ‘over the wall’ management was used to describe a business that operates as a collection of silos, each throwing data and information to other silos on an ad-hoc basis. Variations of this style exist across industries, with the primary measurement being ‘efficiency’ and the response to events being a ‘can do’ attitude of ‘putting out fires’. Being ‘efficient’ through using the minimum of resources in a process looks good, but can be ineffective and an expensive way to operate, because being efficient does not automatically correspond with being effective.

Planning to be ‘effective’ has its main focus on achievable outcomes that include safety margins of time, inventory and working capital. Activities within the business are aligned with the objective to provide improved value for customers and also adapt to changing circumstances as they arise. A competitive advantage can be gained from understanding how to address disruptions more effectively than competitors. “In a crisis, half the impact arises from the crisis itself, while the other half, good or bad, is determined by the response” (McKinsey).

Most companies have a role or group called ‘planning’, but that does not mean there is effective planning. Using an ERP system to run the Operations level materials plan (MRP), but without input and guidance from the Tactical level, via the Sales & Operations Plan (S&OP), is not planning. At best it is scheduling deliveries and operational work for the next few weeks, which requires the ‘planners’ to be in continual reactive mode, expediting resources to overcome the latest emergency. Instead, an effective organisation includes the following attributes:

- Communication of goals and expectations by the profit centre manager concerning improved value for customers

- Alignment of objectives between operational groups and functions

- Cooperation and collaboration in operations planning and scheduling between groups and functions, including the identification of activities and data flows for improvement

- Groups and functions able to adapt to changes and revise their strategies

- Regular assessment of progress against goals, expectations and outcomes, recognising that we behave how we are measured

‘One Plan’ data flow

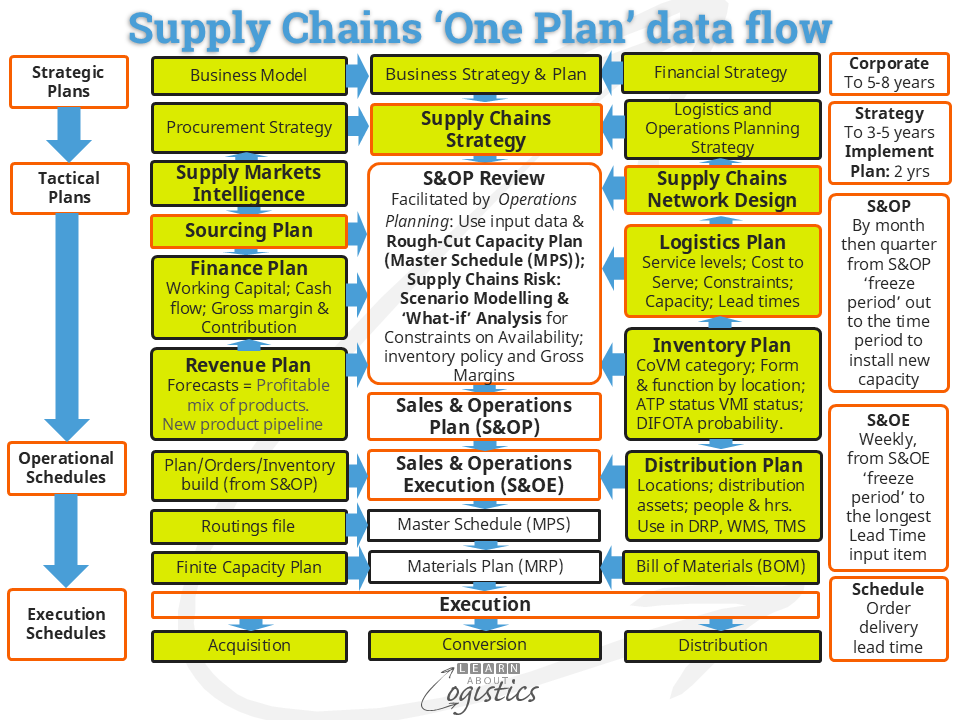

To be effective requires that applicable data and information is available on a ‘need to know’ basis. The diagram below illustrates the ‘One Plan’ flow of internal data, with the time horizons for elements shown on the right of the diagram. This data model identifies the interoperability required between different applications to assist collaboration in decisions. It links the strategic, tactical, operational and execution stages of a business; utilizing the same data sets, but with different levels of granularity.

The diagram shows the Sales & Operations Planning (S&OP) process as the ‘hub’ of the business. The profit centre manager is chair of the S&OP Executive meeting, so a ‘One Plan’ data flow model is best implemented at each profit centre location of a business. Because responsibility and authority reside with the profit centre manager, they have a greater incentive to successfully implement the data flow process. Audits across profit centres can be done to ensure harmonisation of the base data where applicable, noting that Bills of Materials (BOM) differ depending on the customer country’s regulations concerning food additives and equipment safety.

Within the ‘One Plan’ diagram, the elements in white show the flow of Planning and Scheduling; the supporting data and information are shown in green. Each of the elements in the ‘One Plan’ will be discussed in future blogposts. Steps in the Planning and Scheduling data flow are:

- Business Strategy and Business Plan direct the future of the business. They are ‘owned’ by the corporate management team and the main role of profit centre managers is to implement the Business Plan

- The consolidated Supply Chains Network strategy, constructed from the individual function strategies of Procurement, Operations Planning and Logistics

- Sales & Operations Plan (S&OP): requires collaboration to balance the forecast demand for products with the available supply, resources and capacity. The S&OP output is ‘owned’ by the senior management team at the profit centre, but the process is managed by the Supply Chains group and facilitated by Operations Planning

- Sales & Operations Execution (S&OE): takes output from the S&OP to schedule stock keeping units (SKU) that ensures Availability of product for customers. The process is the responsibility of the Supply Chains group and managed by Operations Planning

- Execution Schedules: defines the order in which the operational activities will occur concerning materials acquisition, materials conversion and product distribution. Execution Schedules can be performed as part of a contract manufacturing or 3PL service agreement, but the S&OP and S&OE process should remain as intellectual property (IP) within your organisation. This part of the scheduling process is the responsibility of the Supply Chains group and managed by Operations Planning, but the process and physical activity may be done within operational departments e.g. distribution

The diagram shows S&OE IT applications used in a manufacturing business – the Master Schedule, Materials Requirements Plan (MRP), Capacity Requirements Plan (CRP) and Distribution Requirements Plan (DRP). While each organisation’s planning requirements have similar needs – inputs, capacity available, products/materials available and distribution, the software applications used may have different names.

Developing a ‘One Plan’ approach to the profit centres of your business is the first step in building a culture of planning and scheduling. This has the aim of developing a process that incorporates flexibility for providing a plan at the tactical level which contains sufficient direction for action.