A Supply Chains Network

When considering an individual supply chain in a business, it appears that each step identifies where inputs are consumed and value is added to the eventual finished product. But this picture is not complete. Commentators incorrectly discuss ‘the supply chain’ for a business, which appears to assume that all inputs and outputs for a business behave in the same way, therefore they only need one ‘solution’.

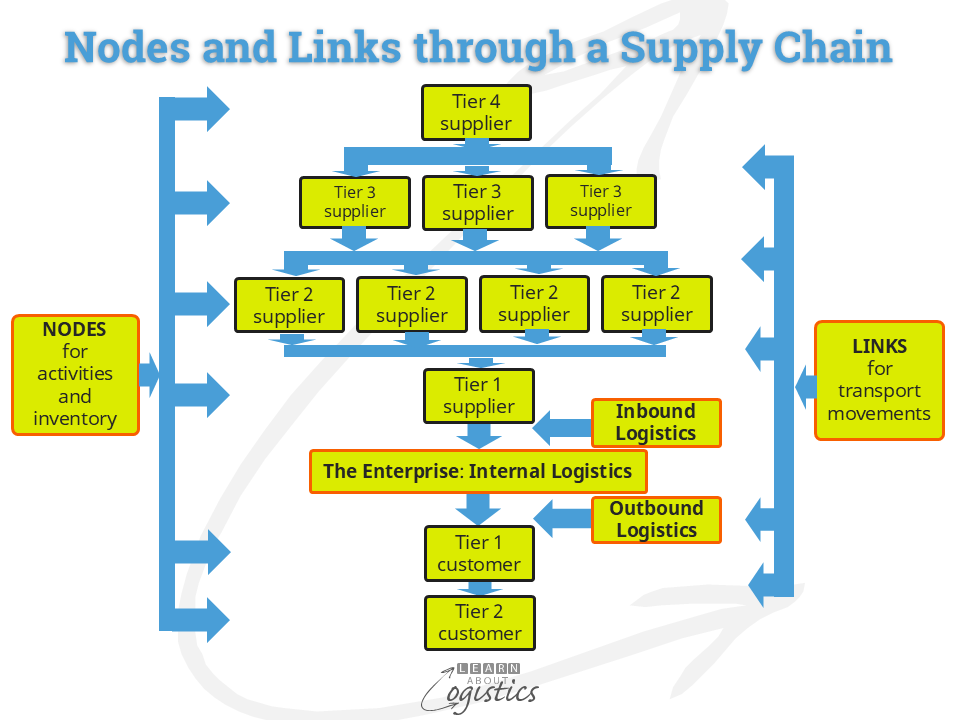

Your business and most other businesses, has supply chains identified as inbound, internal and outbound, within which the individual supply chains are identified by criteria. In addition, through the inbound supply chains, suppliers have their suppliers, which have their suppliers and this pattern continues upstream to the mines and farms for raw materials. Some of these suppliers could also be suppliers to your organisation’s competitors.

This structure becomes the Supply Chains Network for a business, defined by Learn About Logistics as the multiple supply chains that comprise an organisation’s network of interdependent, but connected, suppliers and customers, through each supply chain, operating as a ‘non-linear and complex’ system.

Your organisation’s Complex System

A System is a group of elements that becomes a whole. A Complex System has so many interacting elements that it is difficult, if not impossible, to predict their behaviours in the system. The individual elements of a complex system, such as a Supply Chains Network, are entities that can be interdependent, independent, or dependent, but each can change their behaviour. The degree of complexity in the system is governed by the business relationships within the network, based on the influences of power and dependency and between the system and its environment.

This means that similar events, which have their initial situation known and defined, can produce different outcomes, which are difficult to predict. As conditions change, entities at lower Tiers in supply chains can modify their relationship with other entities, so that a small event in one part of a supply chain can generate multiple events. However, your business is unlikely to be aware of these impending changes, so that performance measures calculated by your business could be misleading, which can then influence computer models.

As your organisation’s Supply Chains cannot be ‘managed’, the Network must be analysed and understood by Supply Chain professionals to provide knowledge. This is gained through gathering supply market intelligence, applying analytics and evaluating risks. Knowledge recognises that behaviour in supply chains is non-linear, that is, there are many ‘ifs and thens’ as in a Decision Tree diagram.

A Supply Chains Network belongs to the type of complex system called a Complex Adaptive System (CAS). Adaptive behaviours Emerge and can be Cumulative as a result of interactions by entities in a system, that respond based on their own interests, which could include a higher level of Operations complexity. Instability for an enterprise can therefore be the result, if too much responsiveness is required from their supply chains.

A CAS is initially described by identifying Nodes and Links, which are the known customers, suppliers and transports in your organisation’s Supply Chains Network. These elements of the system are shown in the diagram, which is the basis for development of your organisation’s Supply Chains Network Design Map.

- Nodes identify suppliers’ manufacturing and distribution facility locations (including outsourced), noting their capability, including capacity and responsiveness and costs (even if estimated) in the core supply chains (Tier 1) and extended supply chains (Tier 2 and below). Also the customers’ warehouse and distribution facility locations. Identify movement Nodes, such as sea and airports, transport hubs and intermodal terminals, noting load capacity constraints and container/pack size limitations

- Variables: identify factors that can change the physical or financial values of items and money at a Node. Examples are changing specific gravity for chemicals and changing interest rates for money

- Links: identify each movement for materials, items and products between Nodes, by mode of transport. Note lead times; cross-border requirements; potential bottlenecks and wait times at country borders and organisations (especially LSPs) that either own, control or influence critical Links. For outbound supply chains, identify customer demand patterns, especially seasonal.

- Time to Recover (TTR) that is expected if transport Links or critical supplier Nodes become unavailable for whatever reason

Complex systems can generate Uncertainty

Uncertainty indicates the lack of predictability concerning the cause and effect of events. The factors that help to provide Uncertainty in supply chains are:

- Complexity relates to the internal systems and processes of a business, often directed or approved by management. Also complicated rules and regulations that are externally imposed, which add time and resources to supply chain processes

- Variability exists at steps through each supply chain: demand, supply, production and shipping movements. Lead times are not static and can quickly change

- Constraints state that the total throughput of a process in supply, production and distribution is governed by a constraint, called the capacity constrained resource (CCR), which is the step in the process that has the lowest throughput

These factors can interact dependently, independently and inter-dependently, which may affect outcomes that increase Uncertainty. The elements are amplified by the level of acceptance in an organisation’s business strategy concerning the:

- Distance (and therefore lead times) from the organisation to its suppliers and customers

- Focus within the organisation’s operations on speed and efficiency rather than being effective

- Safety Allowance that are low when planning time, inventory and working capital

Uncertainty is the basis for Risk Management. All the pressures and influences on your supply chains can be summarised as risks, therefore management of risks through your organisation’s supply chains must be a core capability of the Supply Chains group.

Planning of supply chain processes ideally requires them to be Reliable and Consistent. But to move towards this ideal state requires that groups and functions within an organisation are connected and working together through co-operation and co-ordination. These steps underpin the Collaboration required in an organisation for effective planning.

In summary, the network of your organisation’s supply chains must be recognised as a system, which to be understood requires knowledge. With a confidence from knowledge, the Supply Chains group has more flexibility to recommend changes in the design of supply chains in response to change in geopolitical and business environments.