Your organisation’s Supply Network

Changes to global and regional supply chains are currently occurring through actions by national governments rather than market forces. This could influence how supply chain professionals approach their understanding of an organisation’s extended supply chains and decisions to modify or change business relationships.

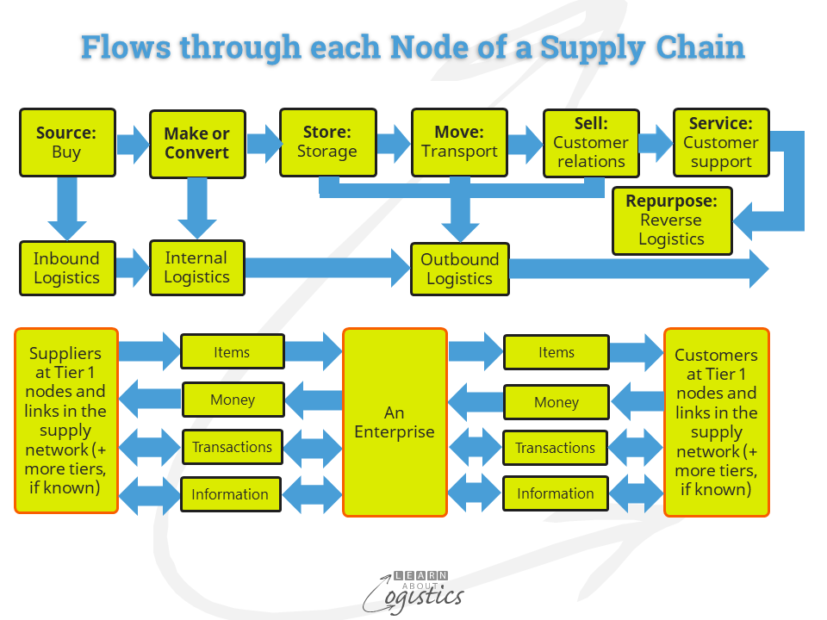

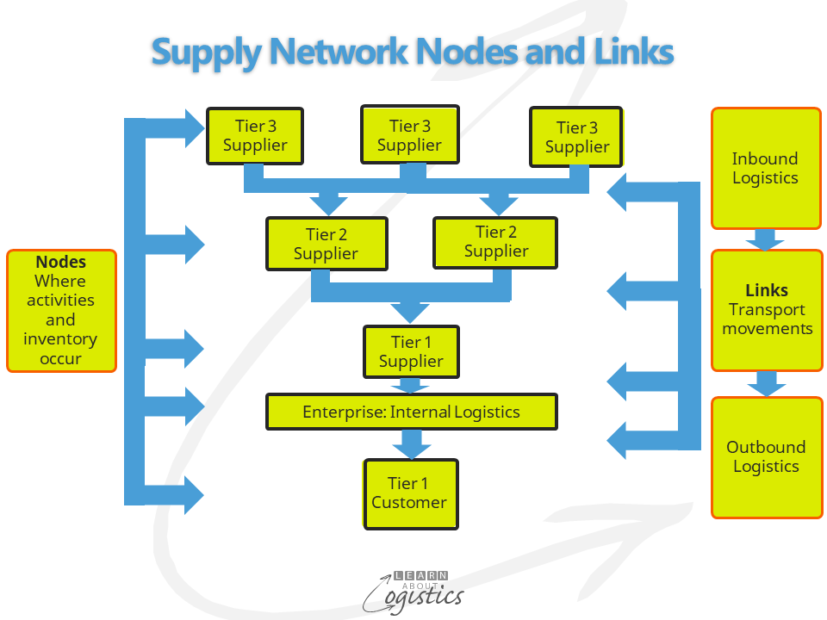

Your organisation’s Supply Network reflects the political, business and physical environment in which the business operates. As shown in the diagrams, a network has individual Supply Chains which allow the flows of items, money, transaction data and information through nodes (which have variables, such as changing values) and links.

The objective of a supply network is ‘…the time-related positioning of internal and external resources to provide Availability of goods and services for customers…’.

Availability is influenced by the attributes that your business emphasises – speed, quality of the process, flexibility, dependability or cost. These attributes are, in turn, influenced by location decisions for adding value and holding inventory based on:

- the volume to weight and value to weight ratios of items

- inventory ‘form and function’ decisions

- lead times and

- security requirements of items

To increase the likelihood of providing Availability, there is a need to reduce risks in the supply chains. Professionals in Procurement, Operations Planning (also called Core Supply Chains Planning – that is between tier 1 suppliers and tier 1 customers) and Logistics, should identify and wherever possible, reduce Uncertainty (caused by complexity, variability and constraints). Uncertainties are converted to measurable Risks by evaluating the likelihood and consequences of events that may affect the organisation and identifying a preferable course of action to reduce or eliminate the risk.

Examples of network risks to be considered:

- How power is exercised in your supply chains by supplier and customer organisations and

- The extent and effects of dependency on your organisation’s supply chains by some supplier and customer organisations

Added to this list are supply chain challenges triggered by new geopolitical actions; evaluating their influence on supply chains and the sustainability of supply for various items.

What are the potential effects on your organisation’s supply network strategy and plans concerning the flows of items, money, transactions data and information through each supply chain?

Focus on Supply Chains

Your organisation’s supply network works as a system. It is a ‘complex adaptable system’ that has emerging responses to events, based on decisions made by different organisations in each supply chain – and your organisation is unlikely to influence the outcomes. However, your supply chain group needs to understand the actual and possible events and responses by affected organisations. This helps to structure your organisation’s response.

In the changing environment for supply chains, focusing on functional performance and improvement is not the path to having effective supply chains. Instead, the functions understood in your organisation to be operating within the ‘supply chain’ heading, need an umbrella vision under which they can work together (such as Availability).

The major challenge to this approach is that the concept of supply chains cuts across the functional structures in an organisation. And people in their functions have a functional view of how things are done – if they concentrate on achieving their function’s performance objectives then (mistakenly) the supply chains are expected to also perform.

This requires a change of mindset; to view your supply network and its supply chains as a system, rather than trying to optimise individual functions. The adaptability and performance of your supply chains will depend on how well people work together within the system, but there is a (normal) reluctance to change, even by senior management.

To emphasise the ‘working together in a supply network’ approach, about five to seven group performance measures are required, for which the supply chain functions will share responsibility. Examples that indicate the cross-function and core supply chains responsibilities are: customer service through ‘delivery in full, on time, with accuracy’ (DIFOTA); Sales and Operations Planning (S&OP) performance; Inventory turns; Return on Invested Capital (ROIC), new product launch and revenue generation and Added Value (if measured).

Additional attributes of Supply Chain professionals

In the past few years, many articles have promoted the view that supply chain professionals will rely on technology solutions to improve the performance of supply chains. However, to address the challenges to supply chains discussed in this blogpost require human knowledge and skills:

- Communicate effectively through different media and styles; writing, speaking and presentation skills to sell an organisation’s objectives and ideas

- Collaborate effectively with others from diverse backgrounds and build relationships

- Empathy with people

- Manage change through: identifying impacts on stakeholders, selling change to senior management and managing implementation

- Problem solving – develop creative solutions through being aware of people’s needs

The changing situation in global supply networks emphases the need for supply chain professionals to enhance their skills in Critical and Creative thinking. This requires the ability to analyse complex supply chain problems, using appropriate numerical skills and techniques; but also to be creative in identifying the paths available to address a problem.

Then, generate wide ranging ideas; evaluating and improving those ideas, by thinking in more holistic ways which remove the boundaries defining functions and disciplines. Of course, this requires an ability to reconcile the tensions and trade-offs associated with diverse perspectives and interests in your organisation. But, remember that technologies reduce costs and people add value.

Even though evaluating patterns and trends in the flows of items, money, transaction data and information will become a critical feature of supply chains in the future, human skills will continue to rank above systems and process skills.