Technology adoption by LSP and shippers

As countries emerge from COVID-19 lock-downs, questions are asked in the media concerned with implementing a different business models and adjustments to the supply chains of businesses. Commentators have also expressed opinions that these actions will increase the use of ‘new’ technologies through supply chains.

This opinion is more likely to be correct for Logistics Service Providers (LSP), which provide goods movement services such as:

- Third party logistics (3PL) – goods movement and storage services

- Transport services (sea, air, road and rail)

- Logistics infrastructure providers (sea & air ports, container parks)

- Logistics Services multi-modal cluster providers – logistics hub, inland ports, freight village

These businesses are focused on customer service for immediate clients and reduction of operating costs. When justifying implementation of additional hardware in their operations they could be more inclined to invest in ‘new’ technologies.

However, what of shippers’ supply chains, which are primarily driven by analysis, planning and scheduling software? As shown by studies over the years, the implementation of ERP systems has not led to improved profitability or return on investment (ROI), while improved customer service and reduced inventory have questionable improvements. Instead, the ‘savings’ for businesses has been in improved planning decisions, which are difficult to measure.

So, for software purchases, the buying decision is more an ‘act of faith’ that it will assist the business. But, is too much faith being placed on ‘new’ technologies that could be at their ‘peak of inflated expectations’ (located within the ‘Gartner hype cycle’ for new software products)?

New software technologies

The ‘new’ software technologies for use in supply chains are (typically aided by the acceptance within business of cloud computing and remote storage):

- Artificial Intelligence, including Machine Learning (the better term to use in relation to supply chains). This is also called Cognitive Computing:

- decision-making enabled by computers ‘learning’ in real-time from data patterns, behaviours and feedback provided by other digital technologies and human interfaces, rather than being pre-programmed to follow a fixed set of rules

- Analytics (analysing ‘big data’ from within and between connected devices):

- Descriptive – explanation for success or failure in the past

- Predictive – using statistics techniques to analyse current and historical data to make predictions about the future and

- Prescriptive – using scenarios to identify the best course of action based on the available data

- Optimisation tools for inventory

- Distributed ledger applications (also called Blockchain) for critical ‘track and trace’ requirements

Whatever the timeline for adoption and implementation, these technologies will eventually become a standard feature in supply chains. However, as always, the challenge of selecting and implementing the software technologies are not technical. They require an understanding of your organisation’s business challenges and capabilities. Examples for these technologies are:

Machine Learning (ML)/(Artificial Intelligence (AI)):

- ML is not magic. Algorithms are designed by people

- If you cannot analyse the solution to the problem using supply chain principles, AI will not work it out

- How to identify mistakes and bias in algorithms? The base algorithms are quickly superseded by the enhancements generated through the learning process

- Algorithm performance and relevance over time. The control process and ‘cleanliness’ of data as it accesses and analyses additional numbers

- Users have visibility to the ML decision criteria and impact of data input volumes. Users monitor and provide input that can override ML decisions

- Security concerning ‘any time’ access to models and simulations of a company’s commercially sensitive supply chain data

Analytics – identifying what is valuable data for the business; accessing the data; poor structure of the data and an inability to understand the data

Optimisation tools for inventory – integration with installed systems

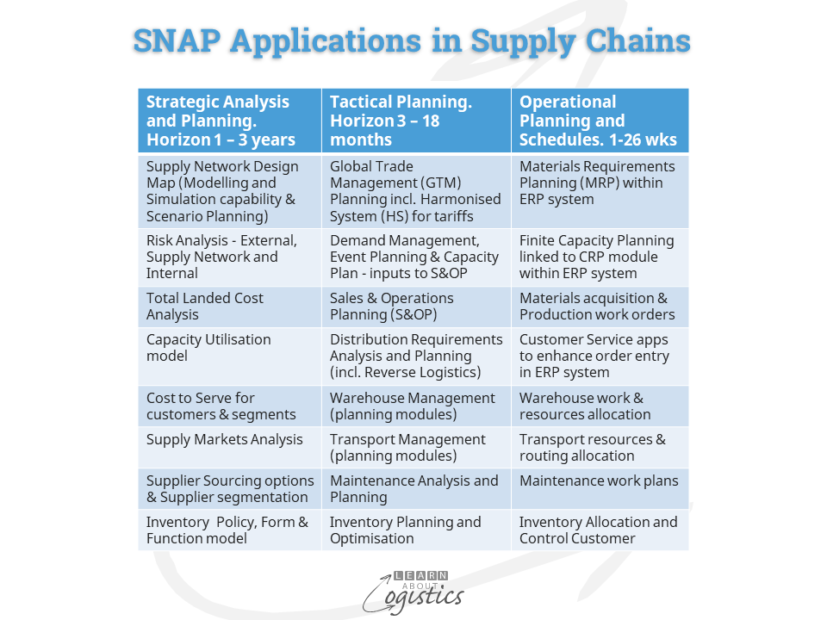

Future releases of Supply Network Analysis and Planning (SNAP) applications will include the new technologies. This will improve access and interrogation of data from markets, distribution channels and sensors that monitor movements of items through supply chains. Then, applying analytics that establish patterns in large data sets.

Skills gap in Supply Chains

As software applications, technologies and tools become an expected feature within supply chain organisations, professionals will increasingly be required to have an understanding of the capabilities and limitations of software technology ‘solutions’.

This does not require supply chain professionals to become analysts – the skill base is very different. As an illustration, the course contents within two free online Artificial Intelligence introductory units are shown at edX and Udacity. However, there will be a need by supply chain professionals to ‘talk the language’, so an understanding of quantitative analysis and modelling applied to supply chains will be required, Additionally, an understanding of Machine Learning and the foundations of object-orientated language programming would assist in discussions with technologists.

Locating learning material by searching the Web can eat up many hours; however, to get started here are a few resources:

The AIMMS Optimization Modelling book provides a no cost introduction to modelling, with worked examples. It is aimed at users who are new to modelling.

A Gentle Guide to Machine Learning provides an overview of the topic

LucidChart allows you to diagram a supply network using templates – value stream maps and process maps are provided.

David Cobby in Recent Comments has recommended the following software apps to better understand supply chain modelling:

ModelRisk a free Monte Carlo simulation Excel add-in that allows probability distribution functions to describe uncertainty about values. Monte Carlo simulation is then used to generate possible scenarios.

What’sBest! is an Excel add-in that allows you to build optimisation models in a free form layout within a spreadsheet.

ExtendSim provides a range of tools for any type of simulation.

As supply chains continue to evolve, so your learning about them must continue, so understanding the fundamentals of supply chains is necessary. Learn About Logistics has free eBooks and downloads, plus the weekly blog. Some consultancy web sites have articles of value, but few Logistics Service Providers have information that assists people to learn about business operations. It is therefore good to see that Allyn International Services Inc. offers four online introductory training courses as a free resource.

If you know of Web sites that feature learning about Supply Chains, please send a Comment.

The supply chain professionals at each node of a Supply Network must understand and respond to Uncertainty in Supply Chain. The COVID-19 pandemic has highlighted Uncertainty in supply chains (with unknown outcomes, costs and time-frames) as a major challenge and which technologies have only just begun to address. This is now your opportunity to master Uncertainty – an increasingly important feature of supply chains.