Your supplier’s motivation.

Buying decisions can be subjective, with buyers possibly having inbuilt bias towards a particular supplier. But one of the challenging aspects of Procurement is to consider which supplier is the ‘best’ for an item or service and is the ‘best’ the right supplier?

Suppliers exist in business to sell you their offer. Potential suppliers can present very compelling proposals for their products or services. Their approach to sales is most likely based on one or more of three ‘values’:

- price (value perception)

- technology (design, engineering, planning and scheduling applications) or

- services (additional added value to provide a ‘package’ of deliverables)

Incumbent suppliers will also be selling, but this can be hidden in the appearance of a ‘partnership’ (a very overused and incorrect term), which can hide a situation where the supplier:

- has become too familiar with the internal politics of the buying organisation and therefore knows how to ‘play the system’

- has influenced the customer organisation to become accustomed to a ‘cosy’ relationship that can breed complacency

- has lost the motivation to bring innovative ideas to the business relationship

With subjective buying decisions and suppliers selling, it is critical that a process is in place which removes as much subjectivity as possible from the buying decision. Therefore, one element of Procurement to be implemented should be an ongoing system that documents the capability of each current and potential supplier – this is the Capability Statement.

Implement the Capability Statement for your suppliers

To better understand the supply market for an item, Procurement needs to engage in a two-step research process. The first step is to research the supply market for a category (identified as a supply industry or a process technology). The second step is to complete the Supplier Capability statement. This is the result of research into the supply base for sub-categories that are purchased by the organisation. However, the actual number of potential suppliers (the supply base) to be researched may be limited by the size and complexity of the factors stipulated in the user requirements.

For ease of comparison, the Capability Statement for each supplier will follow a standard approach for data entry. The buyer or analyst collects the base information about potential and incumbent suppliers through accessing company data and web searches for additional business and product information.

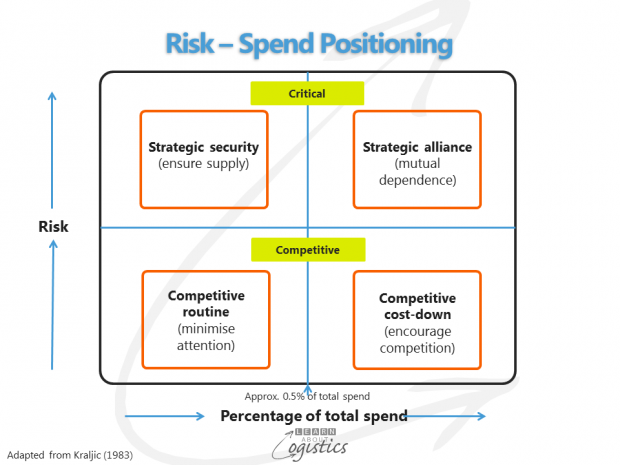

Items with a high risk factor and a purchase value of more than 0.5 percent of the total buy (the Critical quartile in the risk-spend positioning matrix), should have mandatory visits from the buying team to assess the actual situation.

Visits that are to enquire of potential suppliers or to evaluate poor performance by incumbent suppliers will focus on planning and scheduling capability, quality issues, labour practices, equipment maintenance and pre and post-sales support.

If the visit is to a factory, remember three actions:

- Look over the back fence before entering the foyer – this inspection provides current information about operational attitudes at the supplier

- Ask to visit the meeting rooms – even when all data resides in computers, companies like to have good news stories concerning output and quality posted on the wall – but look how current is the information

- Ask for the factory tour to be done in reverse – from dispatch to incoming materials. This makes it easier to pose cost and volume questions (some in ambiguous ways) while viewing the flow

Additional factors that must be considered in the Supplier Capability statement are:

- The share of the supplier’s total business to be taken by the proposed contract

Some are multinational businesses (MNC) will not exceed (say) 5% of sales with any one customer on a global basis; therefore potential customers in a country or region may not be supplied. In countries with a concentration of large retailers, small suppliers may have one customer that provides more than 50% of the supplier’s income. The risk is that other customers may suffer if the large supply contract is cancelled.

- Has the supplier has the financial strength to deliver on the contract.

You can read extensively about analysis of financial accounts; however, it is only in countries that have a strong financial reporting code and legal recourse that financial accounts of companies are available and possibly believable. In other countries, the risk of financial default increases. This is due to the buyer’s lack of knowledge about a supplier’s financial situation, not whether a supplier will fail. Given the additional risk, the buying organisation should have a process to minimise the consequences if a supplier fails to deliver from a country with lower transparency of financial accounts.

Supplier Capability statements are one of the inputs to the Purchasing Strategy for an item. Identifying the supplier capability in a supply market is one aspect of building Supply Market Intelligence (discussed in last week’s blog) that your organisation should be using. The use of supply chain knowledge, based on credible data and information will increasingly differentiate the ‘best’ organisations operating in competitive supply chains.