Supply Chain is a concept

The term ‘supply chain’ was introduced in an article of the early 1980s and its use in businesses began about ten years later, but supply chains have existed since people commenced making and trading items. The publicity concerning international disruption to trade has helped the term enter general conversations, but it is used with limited understanding of the meaning and scope.

The term ‘Supply Chain’ refers to a concept concerning the structure of entities required for delivery of product to a customer and the supply of products, intermediate assemblies, components and materials into a supplying business. There are more than one supply chains for a business, depending on the needs of customers, the type of products and the range of inputs required, so using the singular term ‘supply chain’ to describe all the supply chains of a business is incorrect.

When discussing supply chains, there is not a standard book of definitions. So, ensure that all agree with the definitions being used. Learn About Logistics definitions are used in this blogpost.

Supply Chains: The effective flow of items, money, information and data from the sales channels through to the supplier’s suppliers, that provides value for end users at the lowest total cost.

An organisation’s customers and suppliers are identified by their Tier, from immediate customers and suppliers (Tier 1) out to end users and material suppliers at mines and farms (Tier n). As each Tier of customers and suppliers have their own range of customers and suppliers, the Supply Chains concept expands to become an organisation’s ‘Supply Chains Network’.

Supply Chains Network: The multiple supply chains that comprise an organisation’s network of independent, but potentially interdependent and connected, customers and suppliers.

Complex is the immediate impression of a Supply Chains Network. And this is correct, to the extent that a Supply Chains Network is a Complex Adaptive System. This refers to a system that adapts and organizes itself without a single entity managing or controlling and whose form therefore emerges over time. There are so many interacting parts that it is near impossible to predict the behaviour of the system.

Structure of supply chains

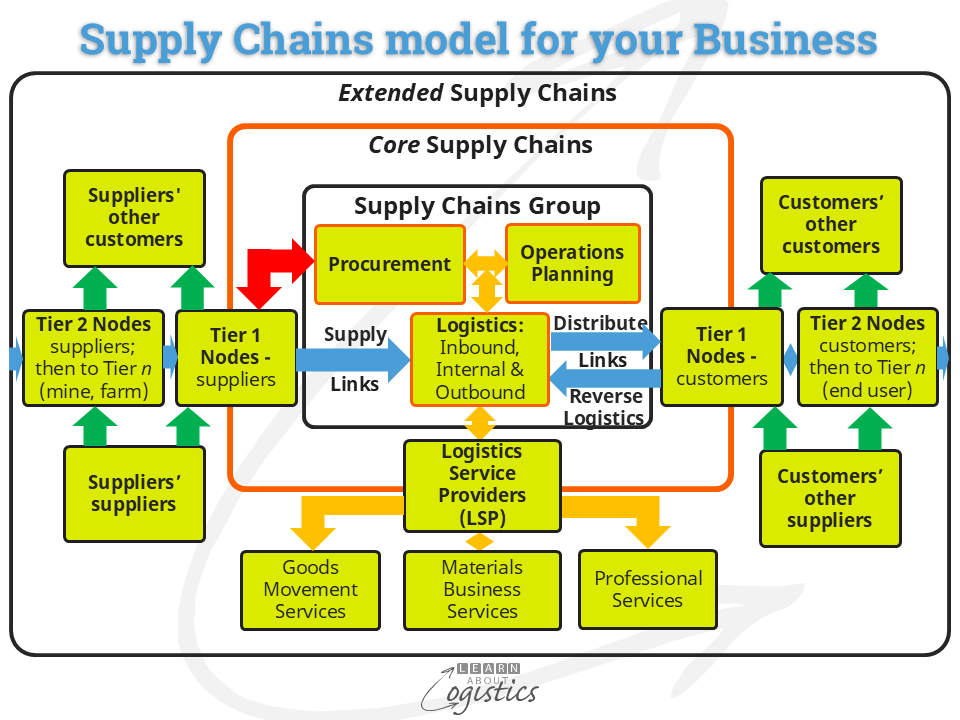

There is not a ‘best’ way to structure your organisation’s supply chains and they are unlikely to be the same as your competitors, because the businesses are different. However, the fundamental parts within a supply chain are the same. The diagram below illustrates the model for your organisation’s supply chains:

There are two designations for the locations of entities at each Tier of a supply chain. They are either:

- Nodes – which hold material, intermediate items, products or money

- Links – which connect Nodes by transport mode movements of products or materials

For an enterprise, each supply chain consists of two parts:

- Core supply chain: incorporates the flows of materials, money, transactions and information concerning materials or products between Tier 1 suppliers, through the enterprise and out to Tier 1 customers. The movements and storage in Core supply chains can be planned and scheduled

- Extended supply chain: Identifies the flows upstream and downstream from Tier 2 supplies and Tier 2 customers. Extended supply chains are unlikely to be planned and scheduled by the enterprise, but should be researched and analysed to gain an understanding

Although supply chains cannot be managed, the three main functions within the Supply Chains Group – Procurement, Operations Planning and Logistics are managed. The Aim of the group is to provide Availability of products and associated services that satisfy the needs of customers and end users.

Availability is the objective of the three functions: To satisfy customer needs by providing Availability of items, through the time-related positioning of internal and external resources, that meet customer and end user needs at the lowest total cost. Availability is required across multiple areas:

- Supply availability: agreed and contracted supply quantities and timing (Procurement)

- Operational availability (Operations Planning)

- Infrastructure availability: maintainability and supportability of facilities and equipment (Operations Planning with Operations Support services)

- Physical availability: place, time and quantity (Logistics) and

- After sales support availability for products (if required) (Logistics)

The overall probability of being Available is measured as In Full, On Time with Accuracy (DIFOTA). This measure is influenced and affected by Uncertainty in both sales and supply markets; at customers; internally; at contractors and at suppliers. Availability is used within the Sales & Operations Plan (S&OP) process, facilitated by Operations Planning.

Mapping for potential risks

The vehicle for understanding your organisation’s supply chains is the Supply Chains Design Map. This identifies factors such as:

- At Nodes: the location and details of customers and capacity and responsiveness in the network of suppliers; the geographic concentration of suppliers,

- At Links: the location and services provided by logistics services providers (LSP); lead times of Links between Nodes; potential wait times and bottlenecks at border controls; regulations for trade lanes

A risk at Nodes and Links of a Supply Chains Network is that entities will exercise Power or Dependency. Both can influence the effective flows of items, money, data and information.

Power is exercised within a supply chain by an organisation that owns, controls or influences selected products and materials or Links. Using Power provides opportunities to gain additional benefits or impose penalties on a supply chain, such as the response to a disruption through the allocation of scarce materials.

Dependency is when a business has a high level of dependency on a supply chain, a customer or supplier for income or purchases. This puts it at a disadvantage and therefore open to pressure when negotiating sales or purchasing contracts with parties in the supply chain.

This blogpost provides an indication of areas for review to improve the workings of supply chains and the effectiveness of functions within the Supply Chains Group. These initiatives and actions are managed within the business, so there is a higher likelihood of achieving success, than attempting to implement new technologies within this year of uncertainty.