Using planning software

A speaker at a recent presentation stated that when the implementation of Supply Chains Tactical planning software began at their company, record accuracy was estimated at about 70 percent. Because there was not an implementation checklist and audit process, where the 30 percent of data that was incorrect remained unknown.

Similar stories have been told since software for Operations planning and scheduling was first developed. As many executives still consider that installation and implementation are the same thing, they allow for a minimal implementation budget. And then they are surprised when the implementation fails.

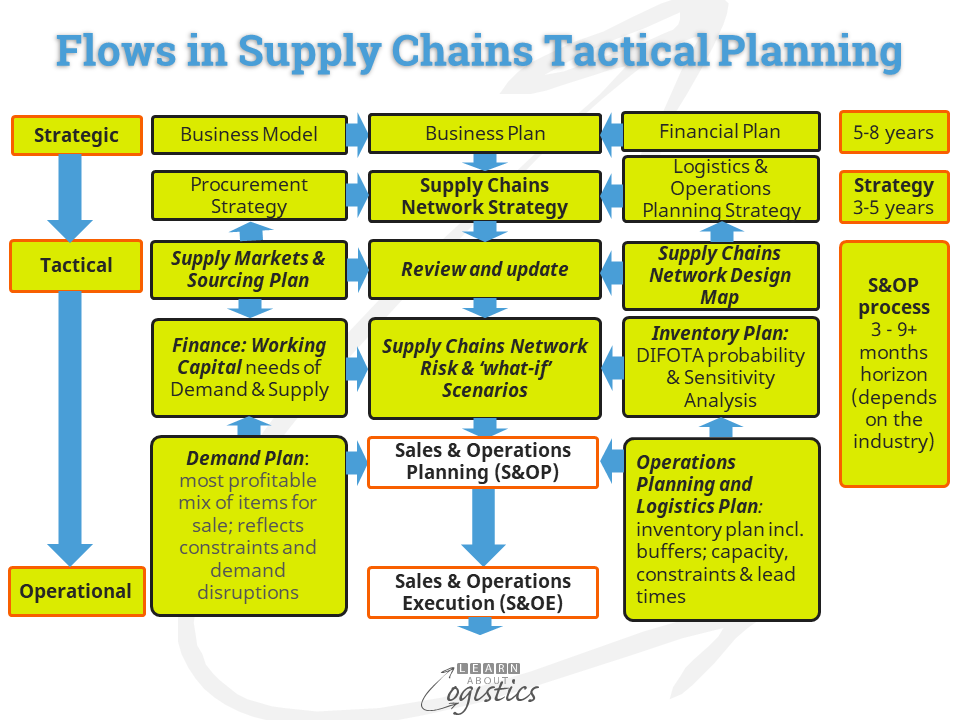

Operational level software for transactional planning and scheduling has been available for many years from MRP, to MRP2 and then ERP systems. Tactical level planning in the form of Sales & Operations Planning (S&OP) principles has existed for more than 30 years.

The diagram illustrates the flows through the planning process. Although not a ‘software driven’ process, a S&OP software application can assist the process. The main elements of data and information that are inputs to the Sales & Operations Plan (S&OP) are in italics. Each element can be enhanced through using computer generated models, with added ‘what-if’ and Scenario Analysis capabilities. But the same implementation challenges remain.

Implementing Tactical planning software

Consultancies and research firms have commented over the years about their experience with implementations of Operational level applications. The low level of success (however that is measured), the low level of real benefits that are achieved and that software is rarely to blame.

With S&OP applications, it would be surprising if more than ten percent of operational businesses have a formal S&OP process that is not just an incorrectly named budget review exercise. Therefore, for many businesses an opportunity exists to implement a rigorous Tactical planning process and when the process is ‘bedded-down’, then implement software applications to help improve the process.

The difference between Operational planning and scheduling applications and Tactical planning applications is that in the former a definitive answer is expected following calculations. In the latter, the answer is what you want it to be, following discussions and computer simulations. Therefore, implementing a Tactical planning S&OP application has specific requirements to be addressed.

Pre-implementation steps

Recognition of the ‘champion’: It is preferred that this person is a manager with a reputation for promoting planning based on S&OP. They are able to set expectations of the total cost, time and effort and potential benefits. As the implementation progresses, they maintain the enthusiasm and help to overcome inter-function disagreements

Appointment of the project leader: This is a full-time role for the duration of the implementation. Preferably it is an internal appointment of a person who is knowledgeable of the business and processes, but who is capable of challenging people and asking questions

Centre of Excellence or Department implementation: Under the Centre of Excellence model, people join a modelling team and develop the model for 6-8 weeks. They then return to their location with the base model and the knowledge to correctly enter data and manipulate the model. The decision required is to what extent will operations planners and analysts (Demand, Procurement, Logistics) be trained to build models or modellers trained in supply chains.

Requirements definition: Written as a business document describe the type of business (engineer to order, make to order, assemble to order or make to stock) and how it generates orders from customers and plans future deliveries and production or imports. Describe the business relationships with customers and suppliers.

Calculate and justify the time and cost to implement: Include the internal and external resources required. The costs of consultants’ fees, training, learning time, replacement staff, testing, data accuracy improvement and documentation. Also, the Post-implementation investment required for education and training of internal promotions and new hires.

Software application selection process: Identify the steps and timing through the selection process. Based on the requirements, identify the criteria for placing a software supplier on the list for consideration and the ‘must haves’ to be on the shortlist. Align software applications with the business processes.

Affected managers agree on the need for Tactical planning: A role for the ‘champion’. Overcoming resistance to change requires selling to functional managers the case for change. To provide ownership of the new application and processes, involve managers and team leaders that will work with the changed processes.

Senior management commitment: This is an important role for the ‘champion’. What does ‘commitment’ require of senior managers? On completion of the above list, the proposal is presented to senior management for approval.

Implementation checklist

Project design and milestones: Do not try to compress the implementation schedule; provide sufficient time for documentation and the examination and redefining of the planning process.

Adequate resources for implementation: Do not try to cut costs by having staff work unpaid overtime on the implementation. A signed commitment is required from managers for the time release of their staff members, according to the implementation plan.

Education and training timetable: As the corporate culture will be impacted by changes in the planning process, consider this as an opportunity for a learning upgrade across all levels in the organisation. Use ‘what’s in it for me and my team’ at all levels

Data accuracy expectations: The data accuracy target must be set, plus how and when it will be achieved. The following components are required for data accuracy in Supply Chains Tactical planning:

- Data capture – software to collect and consolidate data. An example is purchase order (PO) and accounts payable (A/P) spend data, which can be located in multiple IT systems, business units and geographies

- Data warehouse tools for manipulating the downloaded data

- Normalisation – cleaning the downloaded data to eliminate discrepancies

- Classification – code items based on a uniform schema to ensure commonality for the same items. Could use the United Nations Standard Products and Services Code (UNSPSC) or other code structure

- Reporting tool to consolidate and organise data

Point 3 (Normalisation) – for example, discrepancies that are important for Procurement are:

- Suppliers can trade under multiple divisions and businesses, although ultimately owned or controlled by one entity that must be identified

- A supplier’s name can be entered differently in the buying organisation’s accounts payable files. For example, Ford Motor Company and Ford Australia

- Dates to be standardised, as they can be written dd/mm/yyyy, or mm/dd/yyyy, or yyyy/mm/dd

- City names can be written differently e.g New York, or NY, or NY NY

- Multiple general ledger and cost centre names

- Categories and standard industry (SIC) codes may be used in one part of the organisation, but not others

- Descriptions of the product or service can vary, depending on the user

Measure success of the implementation: using selected measurements; include Milestone ‘on time and on budget’ achievement.

Project communications process: Requires a planned communication program. Announce the reason for the Tactical planning initiative and tell all in the organisation of progress on a regular basis. Have modellers, managers and prospective users provide input concerning how they are likely to be impacted by changes in policies, processes and procedures.

The implementation must be led by users – preferably the Supply Chains group and supported by IT. To allow for the unexpected, build time contingency into the implementation plan and do not give it away just to meet an arbitrary implementation date.