Considering future investments

Disruption and changes in supply chains have become a feature that could lead to different strategies and operational tactics. But, how will these changes influence your direction in the selection and implementation of technologies, tools and techniques (3Ts)?

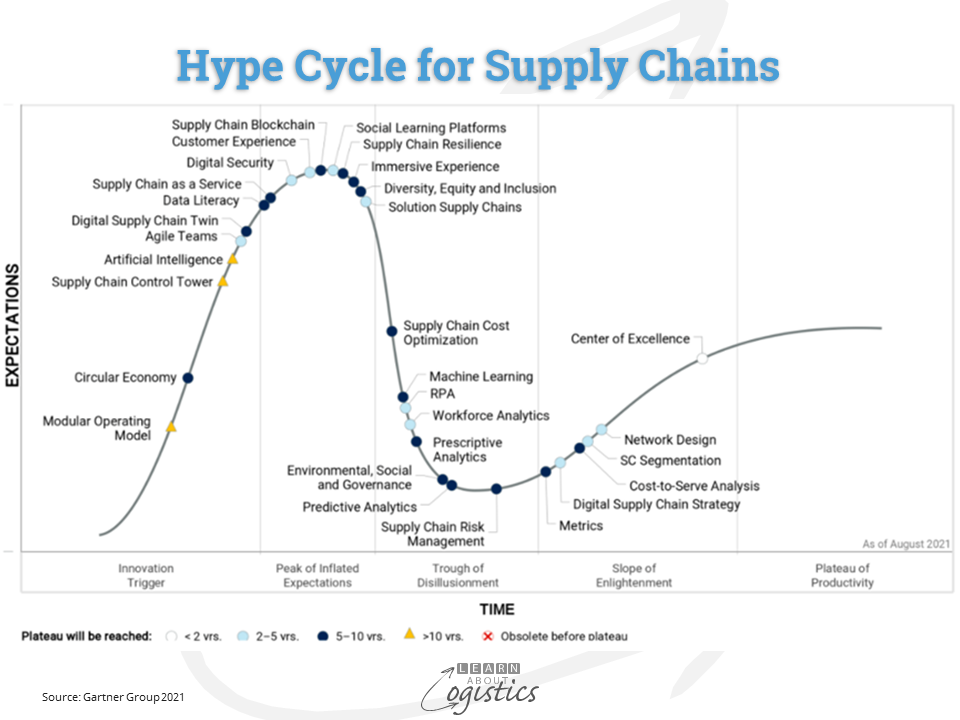

The Hype Cycle, published by the research firm Gartner, provides positioning concerning the announced (and sometimes available) 3Ts that could be used by an organisation’s supply chains group and, if applicable, networked with suppliers and customers. The Hype Cycle’s role is to assist supply chain professionals when allocating their capital expenditure budget towards the more likely ‘winners’.

The diagram provides the most recent Hype Cycle for supply chains. It is but one reference to use and is both a set of assumptions and forecasts, containing all the risks that entails.

The stages through the Hype Cycle are:

- Trigger: an announcement that generates attention in the media, including future scenarios for the technology (always positive)

- Peak of inflated expectation: unrealistic expectations with more implementation failures than successes, some receiving negative media attention

- Trough of disillusionment when too many ‘proof of concept’ projects result in few long-term achievements

- Slope of enlightenment: the remaining users persevere to understand the practical applications of the technology and its implementation challenges

- Plateau of productivity: the technology becomes stable and the benefits are accepted and used within a user community. No longer considered as ‘new’

In supply chains, the approach to technology, tools and techniques will differ by type of user:

- Logistics Service Providers (LSPs) and eCommerce businesses: have logistics as their core business. They are more likely to invest in ‘new’ technologies that are relevant to improving customer experiences and process efficiency

- Shippers: supply chain functions must compete for investment funds against other functions. Structuring a positive ROI and gaining internal support for proposals concerning ‘new’ technologies and software applications for supply chains can be challenging.

Know what you are considering

Of the 30 technologies, tools and techniques identified, three require some explanation:

Modular operating model: An operating model defines how value will be created and delivered to target customers. A Modular Operating Model provides operational design responsiveness to strategy and customer changes, by defining standard building blocks and how to dynamically combine them.

Solution supply chains = Supply Chain Planning Solutions: A platform that allows a business to manage, link, align, collaborate and share planning data across its extended supply chains.

RPA: Robotic Process Automation

For the remaining, an additional challenge is having clarity in your organisation about what each means for the business and the scope, timeline and effort required to implement. The majority of capital expenditure (capex) proposals in supply chains are concerned with IT systems and physical equipment. Tools and techniques that require investment in organisation change and people, through restructure, hiring and training tend not to receive the same attention. This needs to change, as technologies build a closer interface with people.

An example

Centre of Excellence in the Slope of Enlightenment is estimated to reach the Plateau of Productivity in less than two years. Consider this together with Digital Supply Chain Twin, that will soon enter the Peak of Inflated Expectations and take 5-10 years to reach its Plateau of Productivity and Supply Chain Control Tower, which is at the Trigger stage, with more than 10 years to reach the Plateau of Productivity. These can be considered as a continuum of change, with an implementation timeline of more than ten years.

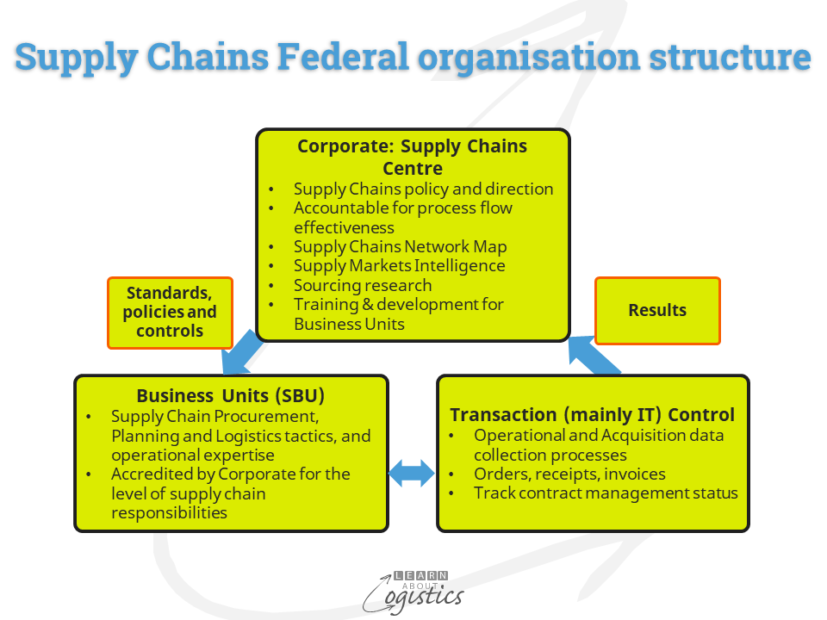

In the early 1990s, the concept of Centre of Excellence was promoted by PMMS, the UK based Procurement consultancy. The organisation structure for Procurement was called the CLAN (Centre Led Action Network) and promoted to organisations with multiple SBUs (strategic business units) or divisions.

The concept was later expanded to address supply chains and included Operations Planning and Logistics. It could also include supply chain finance and supply chain legal. However, it is not an exercise in empire building; PMMS identified that for a Procurement centre, a team of 3-4 knowledgeable people were required.

As shown in the diagram, the structure was federal in design, with the ‘doing’ at the SBU level. The centre provides the strategy and establishes standards, together with policies and controls. It leads strategies for change with the SBUs and provides access to resources – technology, information and training.

The majority of tasks when establishing a federal organisation structure for supply chains is about people and implementing change – maybe that is why the concept has taken 30 years to be accepted (and then not by all). However, the federal structure is the first step, the next is what Gartner calls Digitalisation – “the use of digital technologies to change a business model and provide new revenue and value-producing opportunities“.

This leads along the implementation continuum to Digital Supply Chain Twin. According to Gartner, this is “…a dynamic, real-time and time-phased representation of the various associations between the data objects that ultimately make up how a physical supply chain operates”. That is a long-winded way of saying that it is modelling using direct and indirect inputs. A digital supply chain twin enables the quicker evaluation of scenarios that describe the changing but interconnected relationships between service levels, inventories, capacities and cost./

Using a digital supply chain twin tool positions the centre supply chain group to act as the ‘Supply Chain Control Tower’ for the organisation’s supply chains network. The multiple sources of data and information can be updated from throughout the network and therefore quickly improve tactics to achieve the strategic plan and services provided by multiple logistics service providers (LSPs).

For the centre to operate as a control tower, the business will require superior people skills, in addition to IT tools with outputs that are trusted across the organisation. This is likely why Gartner is estimating that the control tower capability will be more than 10 years before acceptance by industrial organisations.

This discussion illustrates that supply chain professionals need to consider all 30 technologies, tools and techniques (plus others, such as wearable IT) to identify linkages and therefore a continuum of implementations. The total concept needs to be ‘sold’ at all levels within the business and planned for the likely changes to IT and people’s knowledge base.