The supply chains structure.

The strategic requirements of your organisation’s supply chains are first, to gain an understanding of the supply markets that your supply chains rely on and second, use planning and scheduling systems that enable your supply chains to be responsive to your customers’ needs. How the organisation is structured to achieve these strategic requirements is an internal decision.

There is not a ‘best’ way to structure supply chains; your supply network is unlikely to be exactly the same as your competitors, because the businesses are different. How different is dependent on the:

- business structure

- own the core business functions with outsourcing of other functions

- horizontal integration – product variations provided to market segments and geographies

- vertical integration – a supply chain (or part of) that has a common owner

- virtual integration – network of companies to deliver a contract

- conglomerate – unrelated businesses with a financially driven head office

- industry – primary, secondary or tertiary

- type of product

- producer

- converter;

- fabricator;

- assembler

- consumer durables – fast moving consumer goods (FMCG)

- ‘use by date’ controlled – consumer packaged goods (CPG)

- finished product sales & distribution (can include final packaging and test)

- the internal ‘owner’ of products

- divisions, subsidiaries, strategic business units (SBU), geographic areas, product groups

- markets served and how the enterprise views its markets

- domestic – operates within a country

- multi-domestic – domestic business model used for all countries

- international – countries are subsidiaries of the head office

- global – one company image, with standard products and standard processes in all countries

- transnational – ‘think global, act local’ – effectively use global and local sourcing, manufacturing and distribution

- location of suppliers, manufacturing and distribution and the length (time) of their associated links

The structure of your supply chains is also influenced by:

- legal requirements concerning products and operations

- exercising of power and dependency within the buying and selling business relationships

- whether the business is privately owned or publically traded – typically there are different business objectives, even though products and services are similar

Supply Chain elements

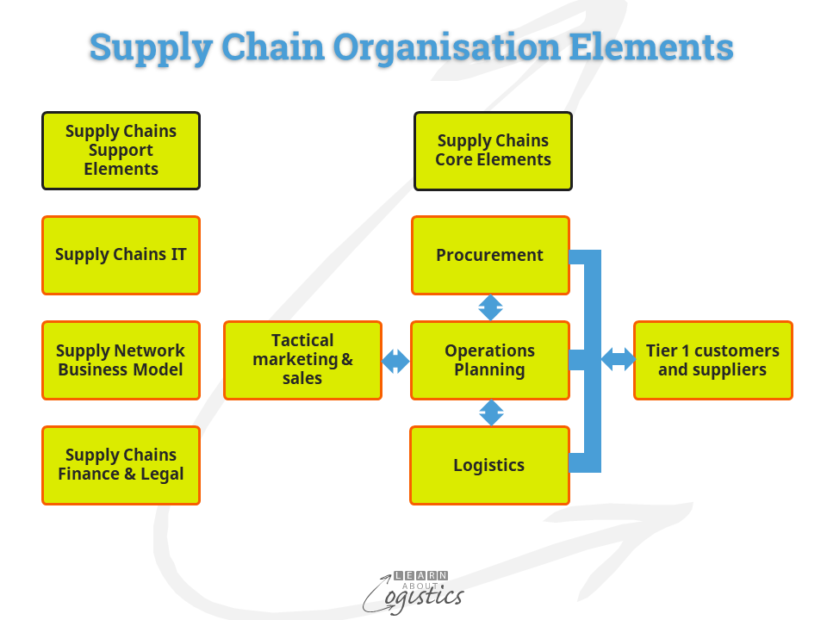

In their own way, each organisation should b trying to e incorporate the various elements of their supply chains into an ‘integrated’ system. The diagram shows the seven elements that provide an organisation’s supply chain capability; that is, to understand supply markets and improve the flow of products and services to customers.

The core elements and their functional processes that relate directly to suppliers, internal operations and customers are:

- Procurement

- Develop and manage the procurement policy

- Sourcing, Purchasing and Contracts for direct and indirect items and services and capital expenditure (Capex) items. Locate centrally or decentralised within divisions, strategic business units (SBU) and subsidiaries

- Procurement analysis (spend and supply markets by categories)

- Operations planning:

- Sales and Operations Planning (S&OP) process

- Master Schedule of manufacturing

- Planning materials and capacity to meet the Master Schedule

- Inventory management (policy, planning and control)

- Distribution plan

- Logistics:

- Schedule the movement and storage of inbound materials and items from suppliers and outbound products to customers

- Reverse logistics movement and storage

- Compliance with trade agreements and regulations for the import and export of materials and products

- Settlement of accounts receivable and accounts payable. This is incorporated in product delivery and materials receipts. It aligns the processes of ‘order and pay’ and ‘deliver and get paid’, with links to Supply Chain Finance and Legal for internal audit

- Tactical marketing and sales. Aligns the product promotion and sales activities with the capability to make and deliver

- Tactical marketing and sales activities, based on the available supply of products

- retail promotions within FMCG and CPG businesses

- Demand management process and input to the S&OP process

- Order management

- Tactical marketing and sales activities, based on the available supply of products

Three support elements assist the process flow concept of supply chains. The type and size of the business and the business model will determine the importance of these support elements. However, the activities exist to some extent within an organisation (or are contracted out) and their output should be recognised as a part of the supply chain process. Responsibilities of these elements are likely to include:

- Supply Network business model

- Consolidate the Supply Chains strategy from the strategies of core and support element individual elements. The number of individual strategies depends on the size and importance of each element

- Supply Chains management model – read about ‘resistance to change’ in the previous blog

- Supply Chains mapping

- Metrics evaluation and performance analysis

- Supply chain analysis

- Supply chain modelling and simulation projects

- Supply Chains IT

- Supply Chains commercial software applications

- Supply Network Analysis and Planning (SNAP) applications

- Supply Chains Communications Network integration

- Investigate, develop and implement viable Digital Supply Chains (DSC) technologies and solutions

- Supply Chains finance and legal

- Management of working capital and cash flow

- Approval of credit for customers and financing arrangements for selected suppliers

- Governance, Risk and Compliance

- governance requirements for dealing with external parties

- identification and management of risks within the supply chains

- compliance with international and domestic laws and international trade agreements concerning supply chains (link with Logistics compliance)

As noted, how the elements are structured and managed and where they fit into the organisation structure is a decision for management.

But, due to the criticality of supply chains performance for many businesses, responsibility for the four flows through supply chains – items, money, transactions and information and their associated processes should be given to a senior person, reporting to the most senior executive (the CEO or Division Manager). Working with the senior management group, this role can influence the business strategy to take advantage of value creation opportunities in the supply chains.

Ideally, the focus of the role should be on improving the flows and processes, rather than managing a function or department based supply chains structure. However, the reality within most organisations is that to obtain integration within supply chains without ‘ownership’ of functions requires a high level of co-operation, co-ordination and collaboration – factors that are typically not in abundance!

So, experience indicates that the tighter the links between each of the seven elements, then a higher likelihood exists of superior performance from your supply chains. This is due to the speed of response as, when required, some activities within teams are quickly combined to execute revised supply chain processes in response to changing markets.