Steps in developing the strategy.

Positioning Supply Chains to be a strategic part of an organisation will take a number of years. A strategy document addressing change in Supply Chains will therefore be a guideline that requires an organisation wide agreement concerning ‘what is to be achieved’?

The extended timeline is because if too many projects about ‘new ways of doing things’ are underway at the same time, there will be competition for resources with the need to manage the current strategy. In addition, each critical step requires changes to the organisation and executive responsibilities, which must first be accepted, then implemented.

The objective for supply chains is to provide Availability of goods and services, to improve the service experience of external and internal customers. How this is achieved is “to meet Availability objectives by reducing uncertainty and increasing strategic advantage, through understanding the range of external complexity, variability and constraints that may affect the organisation and reducing the internal complexities caused by the conflicting objectives of corporate functions” Giancarlo Chiodini, Director of Logistics at Benetton

A previous blog identified seven elements for supply chains. As discussed, it is unlikely that the seven are part of one supply chain function, so initially the Supply Chains strategy should be developed by a team of professionals from individual elements within the Core Supply Chains:

- Procurement – management of external supplier and internal management relationships to meet the supply needs of the organisation and to achieve the lowest Total Cost of Ownership (TCO) for items

- Logistics – provide Availability of products and services for customers

- Operations Planning – balance demand and supply for items, using inventory management, market information and IT applications

The team will have a copy of the current operational strategy for each of the three elements; together they provide an outline of current flows and processes. To see where new ideas and concepts can be incorporated, identify the Moments of Truth. A Moment of Truth is defined as when “a person forms their perception of an organisation in a short amount of time (the moment of truth) and decisions are then made whether to proceed (or continue) with a buy or sell transaction”. In your organisation’s Supply Chains, the Moments of Truth will occur at points through the core and extended supply chains which are specific to your enterprise. However, perceptions about the effectiveness of an organisation are most likely to occur around:

- Ease of buying items and taking delivery from your organisation

- Process for Tier 1 and other suppliers to sell products and services to your organisation

- Suppliers, including Warehouse and Transport (3PL) organisation’s planning, ordering and scheduling your orders, receipts and deliveries

- Internal decision processes to change supply chain processes when requested by customers and suppliers

For each ‘Moment of Truth’ the Supply Chains strategy team will ask:

- What do we want to achieve?

- What opportunities are there for change? and

- What is the likelihood of getting the outcome?

Supply Chains Aim and Objectives

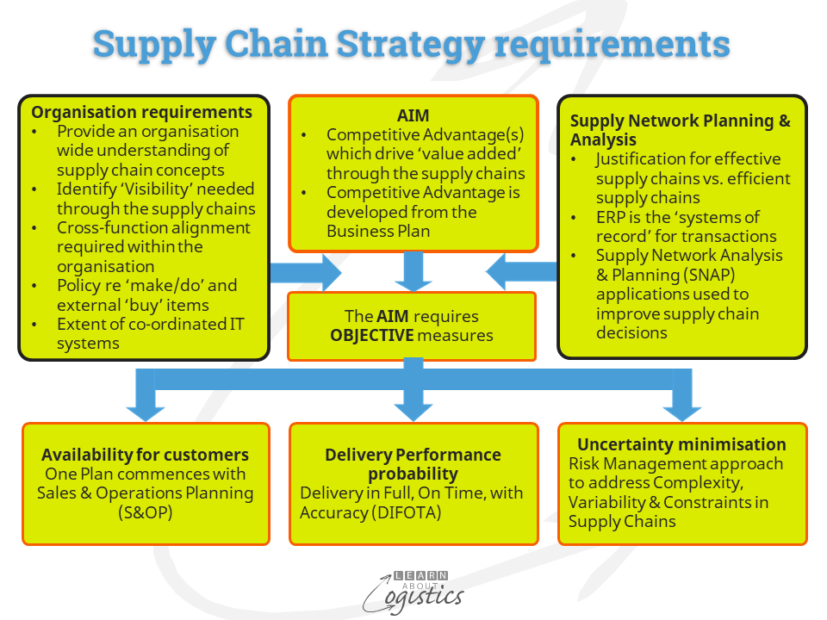

Questions about ‘what do we want to achieve?’ will revolve around the Supply Chains Aim and Objectives, as illustrated in the diagram:

Because supply chains are customer focused, the Aim should address what drives value in the eyes of customers of your organisation. The Objectives to achieve the Aim are based on three established principles of supply chains:

- Achieve a defined measure of Availability for customers. This requires a structured planning process that provides input to schedules. The planning process (One Plan) begins with Sales & Operations Planning (S&OP), which plans inventory to improve the balance between customer market demands, organisation resources and supply markets for materials and services

- Measure the probability of achieving a required delivery performance. The tool used is Delivery If Full, On Time, with Accuracy (DIFOTA)

- Improve Availability capability. This is achieved, in part, by reducing Uncertainty – complexity, variability and constraints in the Supply Chains. To reduce Uncertainty requires a structured Risk Management program

To be effective, each of these Objectives requires additional tools, techniques, data and process steps; these will be discussed in later blogs.

However, within each organisation, the policies, personalities and culture will mean that the observed Moments of Truth must be ranked according to the likelihood of achieving the required outcomes. Taking the highest ranked opportunities, the strategy team can identify the concepts, techniques and approach that provide the best return. They may also be able to identify the: investments in IT applications, people and training required, process steps and changes to current IT applications.

To arrive at this point it is also recommended that agreement is reached at senior levels of the organisation (Organisation requirements in the diagram) to:

- Establish a common understanding in the organisation concerning the meaning, structure and role of supply chains and their value in improving the customer experience with the organisation

- Identify the desired visibility requirements (for items, money, transaction data and information) through the core and extended supply chains

- Establish the extent of cross-function alignment (co-operation, co-ordination and collaboration) required and accepted in the organisation

- Identify the self-sufficiency of the organisation – the extent of ‘make or do’ internally vs. ‘buy’, a reliance on suppliers, including logistics service providers

- Structure IT systems and applications to provide ‘one version of the truth’ for employees, customers and suppliers

Without this agreement, the strategy team will encounter ‘roadblocks’ when implementing the strategy. The team will also need to overcome two misunderstandings that are likely to exist among managers:

- An ‘efficient’ supply chain is not the most ‘effective’. If the main driver is reducing costs, then it becomes very difficult to have a portfolio of metrics that balances growth of the business; customer service objectives and inventory positioning and turns against financial objectives

- Accessing an ERP (Enterprise Resources Planning) system is not ‘integrated supply chains’ in action. ERP systems can provide a record of transactions; however, their operational functionality is limited by the attributes designed in by the provider (which is why you should go through a detailed evaluation process before buying)

- Supply Network Analysis and Planning (SNAP) applications that integrate or interface with the ERP system are more likely to assist supply network decisions. However the selection and implementation requires a higher level of capability by supply chain personnel

The number of aspects to be considered when developing a strategy for new ways of achieving the supply chain objectives means that extreme care is required. Given the level of scepticism about anything new, there is likely to only be one opportunity to develop and present the strategy for approval. So get it right.