Value in a business

The Aim of a business is (or should be) to provide value for customers and end users. Value is the benefits a product (or service) offers its users and the level of satisfaction for the money spent. The challenge is to build value against competitive offerings and to identify and implement an improved value proposition.

To provide value, the Marketing and Sales group and Supply Chains group (Procurement, Operations Planning and Logistics) have defined Aims. For Marketing it is to identify end-user needs and to satisfy them with products and services that create value and generate demand. The Aim of the Supply Chains group is to provide Availability of the enterprise’s products and services to satisfy customers’ needs.

From the Aim, the Objective for a business is to maximise the Value Added or Added Value – the net amount that customers are willing to pay for products above the total cost of purchased items and services. The Value Added identifies the contribution that each product provides to pay for the operating and overhead costs of the business.

Flows and Chains in a business

In too many businesses, there is internal competition between functional groups, with each group or department measured by its efficiency; but without reference to how effective the business is in providing Availability of products for customers. These are an ‘over the wall’ businesses. Only when Marketing has completed the product design and launch document are details thrown ‘over the wall’ for Procurement, Operations Planning (which maybe within Production) and Logistics, typically working as separate departments, to work out how to source, make and deliver the requirements. And, possibly to a tight timetable.

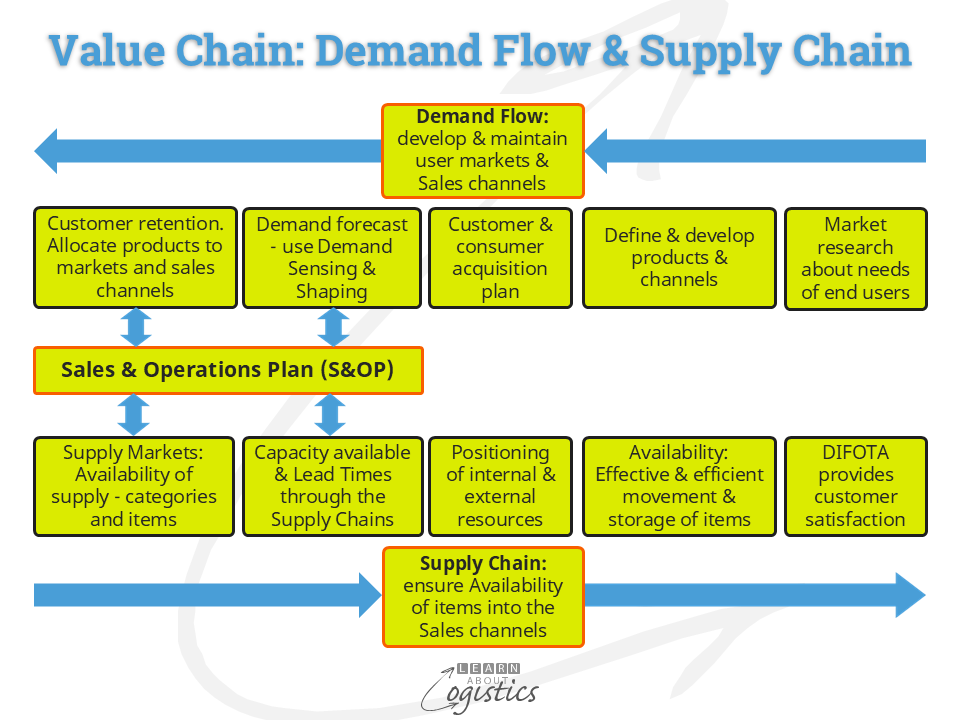

This is obviously not the preferable approach. Instead, the objectives and capabilities within demand and supply should be be jointly evaluated. Then provide a plan over the tactical horizon that is agreed by all affected parties in the business. The diagram below illustrates a Demand Flow and Supply Chain for a product of an enterprise. The flows and chains are complementary, so both must receive equal attention – each is reliant on the other for corporate profit margins to be improved. Together they provide the Value Chain of the business and their connection is through the Sales & Operations Planning (S&OP) process.

A Demand Flow is defined by the market segment in which the product group competes, which can be the sales channel or industry type. Demand flows from market research to product idea to the finished product and customer support, together with defined sales channels and associated sales campaigns.

The Supply Chains group become involved at the time of product development, when product and channel requirements are translated into supply chain capabilities. The outcome is an agreement between Marketing and the Supply Chains group concerning the product range, supply quantities and timing into each market.

With release of the product(s), there is a need to gather external data concerning the user market and product sales (Demand Sensing) and to undertake Demand Shaping through the new (or revised) product launch, promotional pricing, advertising and providing customer incentives in the sales channels.

Inbound supply chains are defined by material type, processes or constraints. Outbound supply chains have their own requirements, including inventory of product lines managed according to their pattern of demand, for example:

- Consumer packaged goods (CPG), identified by ‘use by’ dates. Includes short shelf-life and cool handling (chilled and frozen) products;

- Fast moving consumer goods (FMCG) are durable products, including electronics, household products and apparel;

- Asset intensive products usually moved in bulk loads (e.g. oil & chemicals, metals processing, pulp & paper) and

- Engineered products, including automotive and other transport, aerospace and medical

For clarity, the diagram does not show the many independent but interdependent inbound and outbound chains, which becomes the process for a business to serve its suppliers and customers. In reality, the supply chains of a business are a complex system of multiple inventory Nodes and transport Links, resulting in some businesses unable to identify all their supply chains.

Sales & Operations Planning

To be effective, Demand Flows and Supply Chains come together through the integrative planning process of Sales and Operations Planning (S&OP), which is the ‘hub’ of a business. It provides a structured planning process by which your business has a forum at the tactical level for cross-department collaboration that improves Availability of products for customers.

The objective is to achieve a balance between customer market demands, company resources and the supply of materials and services. However, as an organisation’s supply chains are a complex, non-linear system, the flows between customer’s customers and supplier’s suppliers cannot be managed, only understood through acquired knowledge. This allows a major task of the Supply Chains group to reduce the risks associated with complexity, variability and constraints in the supply chains.

Within the S&OP process, the planning elements of Supply Chains: cost, supply, lead times, service level, inventory, capacity and flexibility must be viewed holistically, because as one element changes it may affect the others. Therefore, these elements must be the responsibility of one group, with Procurement, Operations Planning and Logistics brought together as the unified Supply Chains group.

Operations Planning is the facilitator for departments from throughout the business to become aligned on the agreed Plan. At the conclusion of each period’s S&OP process, Marketing (and Sales), the Supply Chain group and Finance (plus others departments that ‘need to know’) agree on the outcomes required to provide Availability of products over the medium term. The metric for Availability is Delivery in full, on time, with Accuracy (DIFOTA).

People and Planning

The value that is added within your organisation’s Value Chain is the willingness of groups and departments to co-operate across functions. Relying on technology will not overcome deficiencies in co-operation and co-ordination between competing groups. Co-operation leads to the need for shared data, which requires the internal co-ordination of data and information. Shared data facilitates collaboration between functions, building relationships and formulating joint policies, which provides the basis for an effective S&OP process.

People will remain vital to the success of all supply chains, but Logisticians need to be confident in their knowledge of the principles surrounding the planning and scheduling of supply chain operations. The emphasis must be on business focussed outcomes, where ‘People add value; technologies reduce costs’; but avoid poorly defined terms like ‘digital transformation’ and ‘artificial intelligence’ within the supply chain context.