MTO and ATO

Providing Availability of products for customers is governed by the management of inventory, capacity and lead times. Of the three, operational capacity within a business is the resource least influenced by external events and decisions.

As discussed in the previous blogpost, Make to Order (MTO) includes production operations that transform materials, and Assemble to Order (ATO) is to assemble pre-specified and produced items. Both are governed by ‘delayed configuration’ or ‘Postponement’, with the final configuration of an order delayed until a firm order is received.

Management of capacity is the focus when configuring Operations as MTO. This enables flexibility in your organisation’s Operations through aligning production capacities with constraints and the capability of core supply chains to be more Agile. ATO has a dual focus on capacity and inbound inventory, with its benefits of:

- Value of inventory is less, as inventory is held upstream in an unfinished form

- Quick response to changes in demand for finished products, as inventory is held at the part, component or material level

- Inventory held at a generic parts level is more easily balanced with actual orders and

- Forecasting at the generic parts level has less volatility than at a product SKU level

Structure of Operations

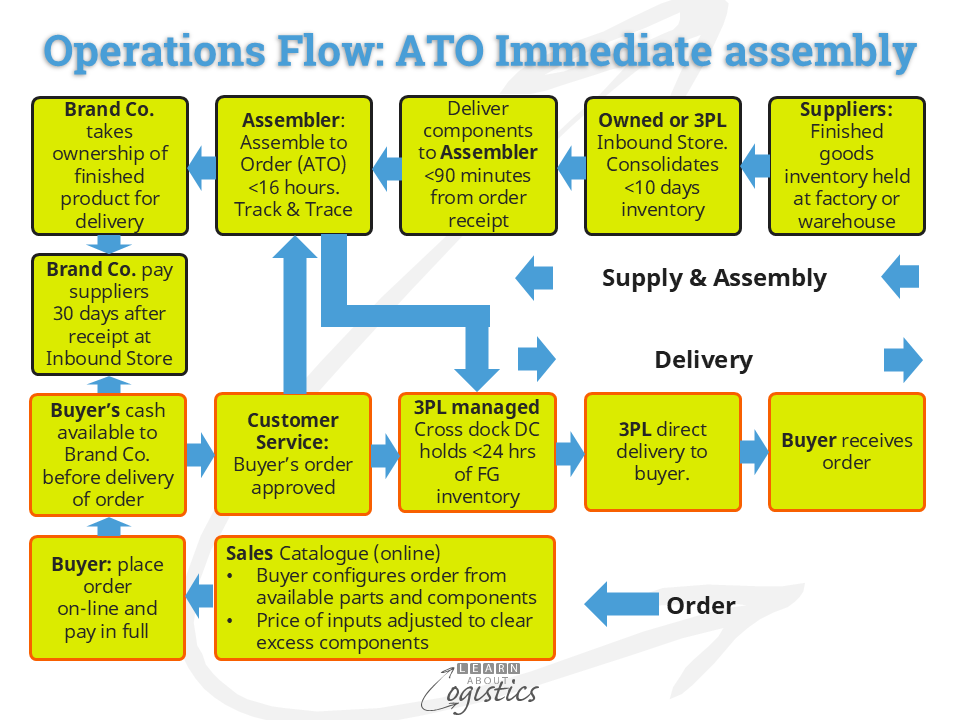

Under MTO or ATO the Operations structure will differ, based on the main driver of the business, examples being: the majority of Operations is Outsourced to contract producers; control the channels of distribution and protect Intellectual Property (IP). Another example is shown in the diagram below, which illustrates the Operations flow for an ATO of discrete parts, where the driver is to minimises working capital – customer orders are cashed before suppliers are paid:

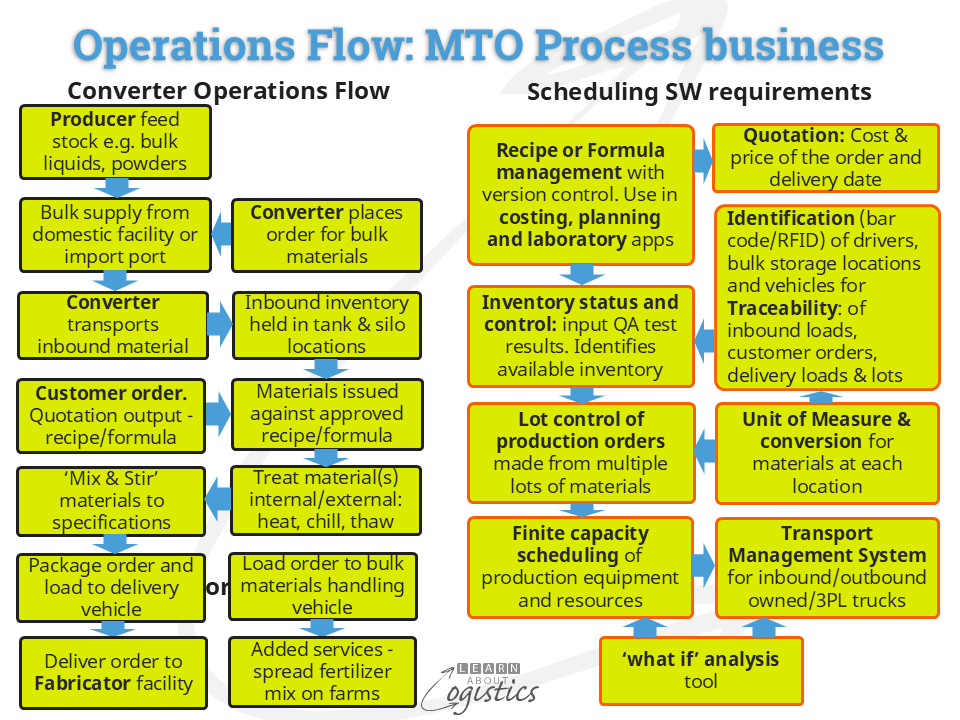

The second diagram illustrates the Operations flow of a MTO Converter business that receives customer orders for ‘mix and stir’ products, which are processed from purchased materials. An additional service is to load specialist bulk handling vehicles to deliver customers’ orders e.g. liquid or air pumping to customers’ tanks or silos or spreading fertilizer on farms:

For MTO products produced from discrete materials and components, there are two types of business:

- MTO Job Shops that service the short-term needs of customers for specialist machine work in cutting, drilling, coating etc. Emergency and rush orders could be up to one third of production capacity. MTO includes businesses that provide Maintenance, Repair and Overhaul (MRO) services, which can include on-site installation with MRO services.

- MTO Equipment Manufacturers sell products that are typically ‘low volume and complex’, manufactured to a customer specification. A customer specifies the ‘one-off’ parts to be produced and incorporated into the finished products, plus the brand and model of options available for the base machine. Each machine is different, being assembled and tested on completion of the production process. More complex products come under the Engineer to Order (ETO) operations structure.

Operations Scheduling will change

Being closer to the customer requires changes to the business relationship. As each order will be different, there must be the capability to quickly answer the customers’ question “How much will the order cost and when can I have it? This is even though specifications and information from customers can be late and not complete, but meeting the delivery date is expected. Pricing must be dynamic, identifying the latest total cost of inbound supplies, and allowing for changing freight rates, government taxes and port charges.

Customers can (and will) want to change their order at any time concerning quantities, staging of delivery amounts and their timing. Also, some jobs have processes or tasks undertaken by sub-contractors. In these situations, the quoted lead times become variable and can affect the production schedule at short notice.

The scheduling application must have finite scheduling capability (FCS) and be flexible to account for quality issues and yields that vary, depending on the precision and tolerances required. Using FCS enables operations to be planned as resources are available (such as specialist machines and skilled labour) and materials are allocated as required for an operational activity.

At process based Converters, the requirements in a scheduling application are:

- Formula and recipe management with separate formula for use in costing, planning and laboratory that include version control and unit of measure conversion for purchased, stored and issued quantities.

- Lot Control to enable traceability of materials and processes when orders do not perform against specifications. It is implemented for customer orders to account for partial deliveries, and for production and supplier orders. This enables order pricing, storage and delivery charges to be identified and calculated. Lot Control Inventory locations per lot are established and deleted as part of business operations, with a history file maintained and accessible.

- Track and Trace capability is required of inbound loads, customer orders and deliveries. Identify drivers, trucks, bulk storage facilities and delivery lots and loads (bar-code or RFID tag) to enable track and trace of lots for QA purposes and accurate payment to contract drivers.

- Transport management is an important cost element for either an owned or contracted fleet. A ‘mix and stir’ process business is usually responsible for the transport of bulk ‘feed stock’ materials into their facility and the delivery of orders to customers’ specific location(s) i.e. farms, factories or warehouses.

Under MTO and ATO, the measurement of Delivery in Full, on Time, with Accuracy (DIFOTA) is a lagging indicator of being Effective. To improve DIFOTA, Supply Chain professional professionals must understand the interactions and inter-dependencies, so that the most impact is gained from the fewest changes.

A critical change is implementing Sales & Operations Planning (S&OP) as the tactical planning process. It is at this level that underlying customer demand and weighted forecasts of possible orders are evaluated; based on geopolitical events, supply chain disruptions, economic changes and customer requirements for product customisation. The S&OP process must therefore incorporate supply markets intelligence concerning critical inputs, including complex and ‘difficult to replace’ parts, together with the organisation’s resilience capability and possible responses under scenarios.

Uncertainty is the common factor for businesses when considering how geopolitical events may impact operations in the next ten years. Some organisations will decide that the best response is to wait for less uncertainty. However, the current disruptions could be the start of a geopolitical re-alignment, with more uncertainty; so, for businesses it is better to invest in flexibility to become a more Agile business, even when it is Make to Stock.