A new ‘buzz’.

Over the last eighteen months, the term ‘consumer-centric network’ has been used by some commentators and consultancies. So, what is new, because whenever there is competition for sales of an item or service, the customers’ needs should be taken into account.

The explanation is that in current value and supply chains, the consumer is positioned at the downstream end of the chains. In value chains, the end users are supposed to start the process and for supply chains, the customer/consumer is supposed to receive the order in full and on time (that is Availability).

However, the commentators say these chains are built on relatively static relationships between organisations and are designed around each organisation’s internal processes. They are usually supported by information systems and data storage which are in silos.

Over the past five years, articles have promoted collaboration (often without accepting that co-operation comes first), through connecting information between organisations based on standards, shared processes and data. However, the argument states that any co-operation and collaboration between organisations is linear through a supply chain; mostly between large retailers with buying power, larger (often MNC) manufacturers and their tier-one suppliers.

Outside-in vs. Inside-out

The ‘new’ scenario says that a consumer-centric network is different. The description of the new model is that it is designed from the ‘outside-in’, whereas the current supply chain structure has a linear ‘inside-out’ approach.

The new networks will be designed around consumers being at the centre, with multiple buying and delivery channels linked to sourcing, manufacturing and distribution. There will be interfaces between consumers and suppliers, such as interactive dialogue (help desk), product updates and sales.

The networks will be connected through hubs provided by business services; all parties can use the network whenever and wherever they wish to gain information, buy products and services and pay money.

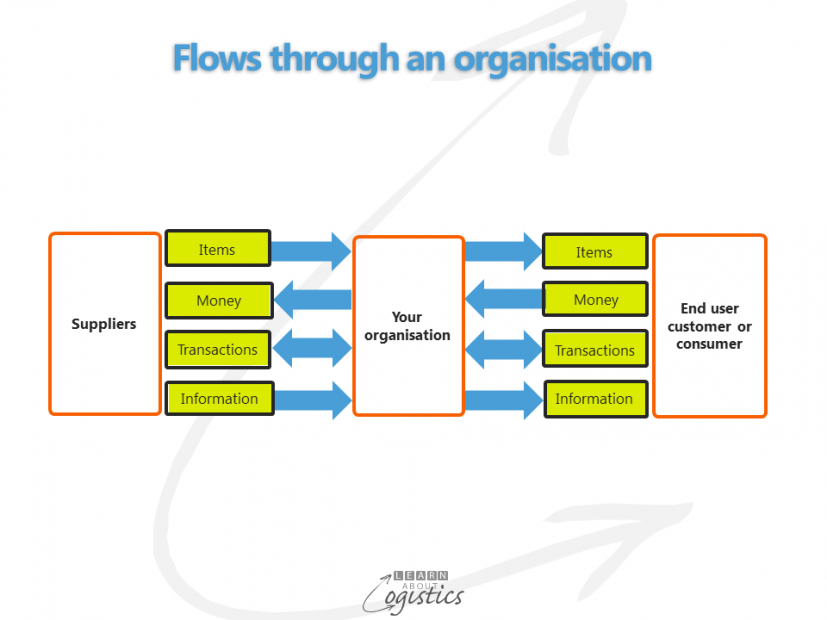

As shown in the flow diagram, the network enables business transactions (transaction flow), financial movements (money flow) and deliver the items required (physical flow). In addition is the information flow to provide relevant information. It is thought that ease of access to flows in a network will help to improve relationships between retailers, brand manufacturers, logistics service providers, suppliers, governmental bodies and NGOs.

The interconnected networks cannot be managed like the current value and supply chains that are industry-driven. Instead, simultaneous activities occurring at different tiers of the network will utilise new technologies (mobile, wearable) and use protocols to maintain order (similar to road rules for road networks).

A bit too futuristic

Although the commentators write their articles as though the new networks are here and working, we know that is not true. The time between an idea and its implementation on a wide scale can be decades, especially if many individual organisations, each with their own objectives, must be involved.

That said; do not dismiss the idea as fanciful; use it as a guide to direction. With technology improvements (and organisation acceptance), the concept may take ten or fifteen years to become a part of daily life for people, although early adopters will embrace it earlier. The question is, what does your organisation need to do (and when) to get on the road for consumer-centric networks?

The first step, of course, is to have every person in your organisation speaking the same language. What is a supply chain, or a supply network? What is a value chain and how does it differ from a supply chain and where does Logistics come into the picture?

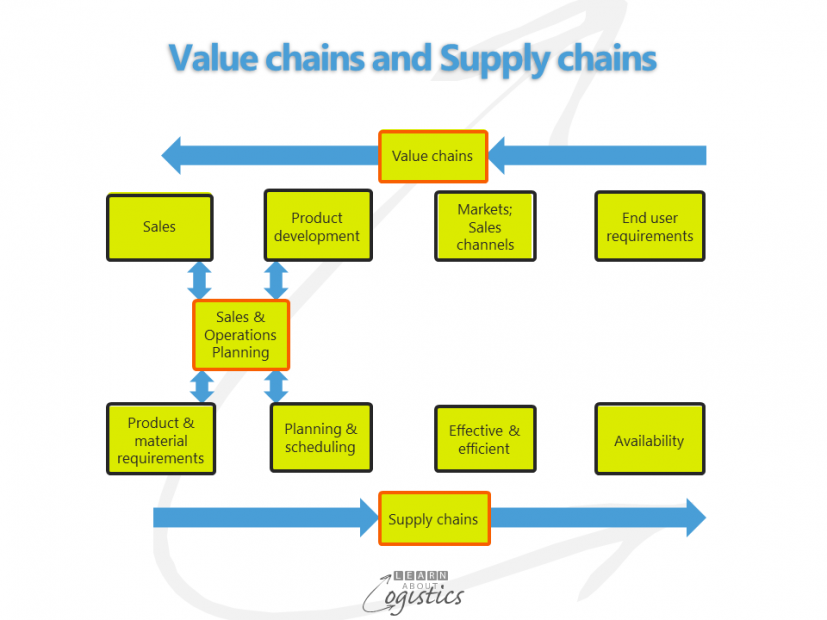

The diagram shows a value chain and a supply chain. A value chain “creates value in the eyes of the customer” and therefore commences with the customer/consumer. A supply chain commences with the product and material requirements (the need) that enables Availability of the item for the customer. Many chains make a network, which your organisation has, although it may not be recognised.

The link between the two chains is the Sales & Operations Planning (S&OP) process; without it your organisation has a medium term problem. The driver of the S&OP process is the supply chain group, comprising Procurement, Material conversion/production and Logistics. Without each function ‘singing from the same music score’ your organisation also has a medium term problem.

Why will there be a problem? It is because your organisation cannot start to become ‘customer/consumer centric’ (different from being sales focussed), without being Dependable; that is, keeping promises. Being Dependable is reflected in the probability of meeting future contract obligations with customers and the performance measure is DIFOTA – ‘delivery in full, on time, with accuracy of all processes’. The more that systems and processes within your organisation are flexible but robust, changes in the wider environment, such as capacity constraints and weather can be overcome without affecting Availability for customers.

So here are the first four steps along the road to becomming ‘end user centric’:

- A common language about chains and networks

- Implement S&OP

- The core supply chain group has one head

- DIFOTA is the measure of future customer service capability