Challenges for global trade

The current uncertainties in global trade will challenge companies to review the effectiveness of their supply chains. If the uncertainties convert to real risks for businesses, then over time, there is the potential for a realignment of trade relationships and the emergence of different economic blocs.

For improved economic cooperation, these trade alliances could be structured for greater resilience based on: ethnicity and language (such as the Organisation of Turkic States in Central Asia), legal systems, political structures or colonial legacies.

But how would these changes affect the operations of supply chains within a business? The Aim of your organisation’s Supply Chains group (Procurement, Operations Planning and Logistics) is ‘…the time-related positioning of internal and external resources to provide Availability of products and services for customers…’. However, the Supply Chains Network of a business is a complex, adaptable system that is non-linear in design, with many ‘ifs and thens’ questions to be analysed.

There is also a lack of information and data generated through supply chains. This adds to the difficulty for an effective response to disruptions in supply chains and adapt to sudden changes in demand by customers, supply lead times and transport delays. Complex Supply Chain Networks cannot be ‘managed’ – there may even be difficulties in managing the immediate core supply chains between Tier 1 customers and Tier 1 suppliers.

Improve Operations Planning & Scheduling

In response to the challenges, commentators note that to improve achievement of the Aim, companies are considering an expansion of supplier numbers (even though building business relationships with more suppliers is difficult), and sourcing from suppliers that are geographically closer (currently called ‘nearshoring’ and ‘reshoring’).

However, the consulting firm McKinsey noted in a February 2025 article that there is “no overall trend toward diversification of supply” or that “nearshoring does not yet appear to be happening on a global scale”. Also, DHL has noted that global trade is moving over longer distances, with the average distance for traded goods at a record 5,000 km in 2024, while intra-regional trade declined to an all-time low of 51 percent.

What is not mentioned by commentators is the potential for improvement of internal Operations Planning and Scheduling systems and processes of an enterprise. For this to happen requires that first, skills are increased concerning the design and functioning of Sales & Operations Planning (S&OP) and Sales & Operations Execution (S&OE) and second, that knowledge is increased about your organisation’s Supply Chains Network. This is about the Flows of items, money, information and data through core supply chains and the activities at suppliers and logistics service providers in the extended supply chains and their wider network. Also, as supply chains are influenced by geopolitics that surround the Network, there must be an increased understanding of external influences, such as geopolitics and climate change.

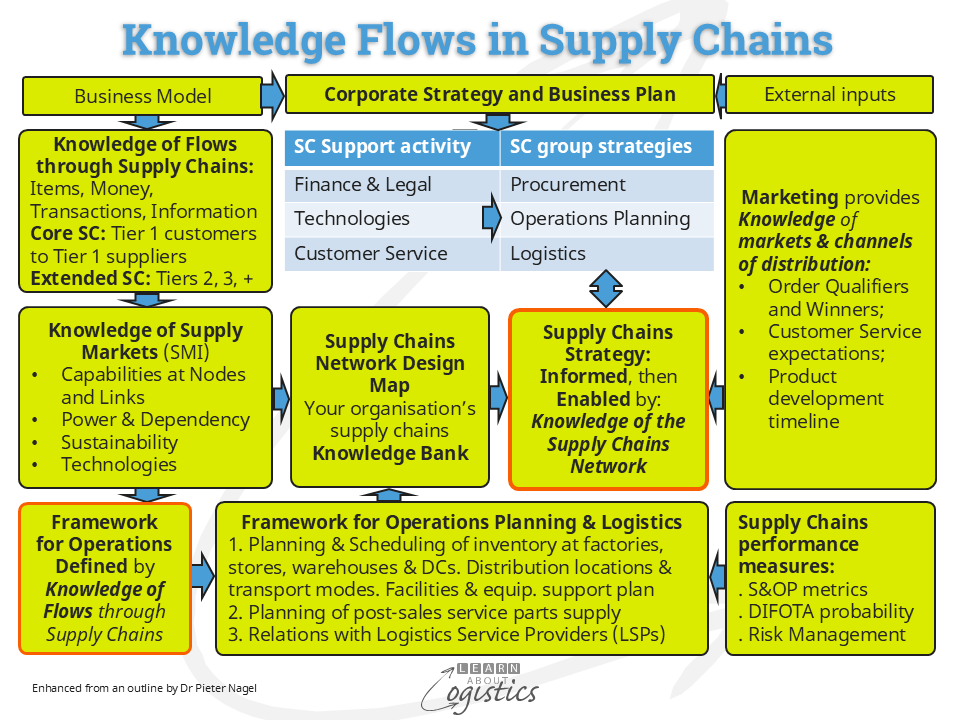

To be effective, the knowledge gained needs to be formalised for use as an input into the Operations Planning process and ideally, the Business Plan. The diagram below illustrates how knowledge of your organisation’s supply chains and their wider network provides essential input that enables the Supply Chains strategy and defines the framework for Operations.

Build Knowledge for Supply Chains

The Supply Chains strategy is informed and then enabled by knowledge of your organisation’s wider Supply Chains Network. This comprises the Core and Extended supply chains from the customer’s customers to the supplier’s suppliers. As shown in the diagram, knowledge is obtained to build:

- Strategies of functions in the Supply Chains group (Procurement, Operations Planning and Logistics). These contain input from the corporate strategy and business plan, plus the supply chain support functions of finance and legal, technologies and customer service

- Customer markets and channels of distribution, identifying order qualifiers and winners, customer service expectations and the product development timeline

- Supply Chains Network Design Map – your organisations Knowledge Bank. The Design Map contains current knowledge about the supply chains and their environment. It is informed by knowledge of flows through the supply chains of items, money, information and transactions, plus Supply Markets Intelligence (SMI)

External knowledge that must be learned at a ‘competent’ level by supply chain professionals addresses:

- Geopolitical situations and their potential effects on international trade and the organisation’s supply chains

- Policies of national governments in customer and supplier countries that may affect or influence decisions concerning the organisation’s supply chains

- Concentration of supply and potential risks at the sources and then through intermediate stages of production

- Availability of materials and intermediate goods and the influence of critical materials (however defined) on the organisation’s supply chains

- Futures markets and their influence on the pricing of the organisation’s raw materials (even if not directly supplied)

- Global demand and supply (and cost) variability for types of transport and other supply chain services

- Climate Change risk analysis and adaptation action to reduce vulnerability and identify the likelihood of storm damage, floods, fires and water shortages at customer and supplier locations

Also, the knowledge required to meet requirements from government agencies for data concerning supply chains, which could increase substantially in the future. These demands may address particular aspects related to supply chains – the environment and natural capacity depletion; stakeholder needs and expectations and governance through the supply chains.

The diagram above indicates that the framework for Operations Planning and Logistics is defined by the knowledge of Flows through the supply chains. These enable the identification of planning horizons and freeze periods, scheduling constraints, distribution locations and transport modes. In addition is the knowledge required for building business relationships with Logistics Services Provider (LSP) businesses.

Building internal and external business relationships enhances the level of trust both internally and at least with Tier 1 customers and suppliers. From co-operation, to co-ordination, then collaboration, which requires working towards a common goal and building on shared opinions, expertise and knowledge to enhance thinking about planning supply chains. This is required because only about 20 percent of the scope for a change to an organisation’s supply chains is within the direct control of the Supply Chains group or its Logistics function. The remaining 80 percent requires collaboration to share information, expertise and knowledge with parties in the supply chains.

However, learning and building knowledge is not a feature within Supply Chain Networks. So, to enhance the value of building knowledge, supply chain professionals need a performance measure for learning. Included in the measurement is the extent to which, after knowledge has been acquired, transferred or adopted, there is a willingness to share and disseminate the knowledge within the Supply Chains group and within the organisation on a ‘need to know’ basis.