Supply Chains of your business

A reader has asked which of the many elements of supply chains should be emphasised as companies take steps to change the objective of supply chains from ‘cost down’ to ‘value add’, in an era of disruptions?

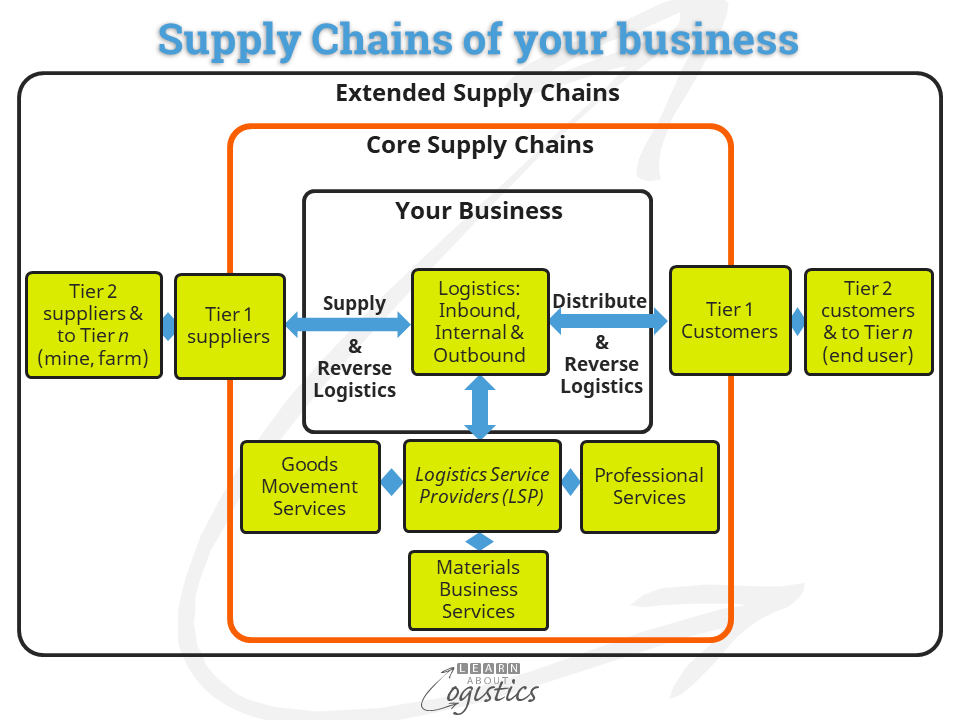

While each business will select its own list of short-term ‘to do’ actions to achieve improvements, there should be an overarching recognition that an organisation operates within its Supply Chains Network; it is influenced in its strategies and tactics by the activities of all parties within its Network. The diagram illustrates Supply Chains.

A Supply Chains Network has each supply chain reflecting its ‘flow’ of items, money, information and data, both inbound and outbound from a business. Each of the about five to nine supply chains of a business has the ‘core’ supply chains comprising the business and its tier 1 suppliers and customers. The ‘extended’ supply chains comprise the interactions between tier 1 suppliers and customers with level 2 and so on. However, as each of the suppliers and customers interact with their other suppliers and customers, these business relationships are often unknown to the focal business.

The opposite ‘flow’ to supply chains is the demand chains, spanning from market research through to product design, sales channels development and the demand plan. Together, the supply chains and demand plans make Value Chains.

Areas to emphasise in your Supply Chain Network

Given the outline diagram above, together with lessons learnt over the past years of disruptions, Learn About Logistics considers that four areas should be emphasised as a prerequisite, when implementing actions for improvements to your supply chains.

The first prerequisite is the recognition that Supply Chains cannot be ‘managed’. This is because a Supply Chains Network is a ‘Complex Adaptable System’. Each Node and Link in the Network of a business responds to a major unplanned event in its own way, which makes for complexity. The more nodes and links, the more complex the system. When a major unplanned event occurs, nodes and links respond to protect their business, but the Network will eventually adapt without any central directive and return to some form of equilibrium (as is now happening with regard to the ocean container trade with a slowing of supply from China). Attaining equilibrium takes time and can cause further disruptions, which can be interlinked, generating more complexity. Logisticians need to understand their organisation’s Supply Chains Network.

The most secure part of the Network should be the ‘Core’ supply chains. The business relationship can be respectively managed by Procurement and Sales, such that your organisation knows and can respond to the drivers and concerns of these critical parties.

For the ‘extended’ supply chains, your business needs to understand its Supply Chains Network, including the source and availability of critical materials and specialised intermediate items. Using Supply Chains Mapping, Logisticians can see the structure of their organisation’s Supply Chains Network and this provides the basis for how best to respond to unplanned events.

The second prerequisite is recognising the role of Logistics to provide Availability of items for internal and external customers; other tasks are there to support the role. Availability requires that Inventory is available to decouple demand and supply, or to provide a buffer. The definition of inventory is ‘items purchased and made by a business, but not yet sold’. This can incur substantial holding costs that affect working capital, so Inventory Management is also important from a financial viewpoint. Inventory Management comprises policy, planning, performance and the quantitative analysis required to optimise inventory and is a critical element when responding to unplanned events. The role of inventory is discussed in an earlier blogpost.

The third prerequisite is Sales & Operations Planning (S&OP), which is the ‘heart’ or ‘hub’ of a business. It is a structured planning process by which your business has a tactical forum for cross-department collaboration. The objective is to improve the balance between customer market demands, company resources and the supply of materials and services. Depending on the planning needs of the business, flexible operations plans can be provided for up to the next 24 months. In addition to the use of S&OP in shipper organisations, the main elements of S&OP, the demand plan and the capacity plan, can be used throughout supply chains, such as at bulk loading terminals and shipping container parks.

The fourth prerequisite is that people will remain vital to the success of all supply chains. The emphasis should be that ‘People add value; technologies reduce costs’. Logisticians need to be confident in their knowledge of the principles surrounding supply chains and must understand (but not necessarily operate) the various technologies on offer. This enables them to consider the potential limitations of technologies, so that mistakes are not made at higher speeds!

For example, Artificial Intelligence (including Machine Learning) appears to be the most mentioned technology, even though it is not the most implemented. Toby Walsh, Professor of Artificial Intelligence at the University of New South Wales (UNSW) in Australia has recently written with reference to AI “Move slow and for god’s sake be careful”. He notes that AI remains in the experimentation phase, therefore the development of algorithms can have unintended consequences that could be difficult to unravel. This is because, as AI updates and learns, the initial algorithm is difficult to recover, therefore humans are less able to identify the root cause of failures and bias in algorithms. Toby Walsh also says that people in an organisation should challenge the fallacy that computers never lie and ask how AI used in their business makes decisions. He says that even when humans remain as the ultimate arbiters for decisions, they are more likely to accept the machines’ recommendations, due to ‘autonomation bias’.

With the four prerequisites in place, the supply chain group are in a position to ‘value add’ through exploiting the attributes of time and place, which can provide competitiveness for the business. The attributes are: quality of the supply chain process (and is resilient and adaptable); flexibility (responsive and agile); dependability (reliable and aligned with customer and supplier needs), speed and cost.