Supply Chain models

While it is commendable when complexity is removed from an organisation’s supply chains operations and its core supply chains, consideration must be given to the supply chains model that the business and Supply Chain group (Procurement, Operations Planning and Logistics) operate within. Working to remove complexity from an incorrect model is not a good use of resources.

What is a supply chains model? It identifies the main factors that illustrate how a system of physical items, data and information flow. These enable the Supply Chains group (and therefore the enterprise) to provide Availability of products and service for customers, that will experience ‘delivery in full, on time, with accuracy’ (DIFOTA).

Many attempts have been made to develop supply chain models, but the majority do not consider all the flows, only the aspects of delivery from a business to its customers. A rethink of what a supply chains model should look like is required that aligns with thinking about the role of products in society, the scope of a supply chains organisation and the need to reduce the impact of climate change.

A new model

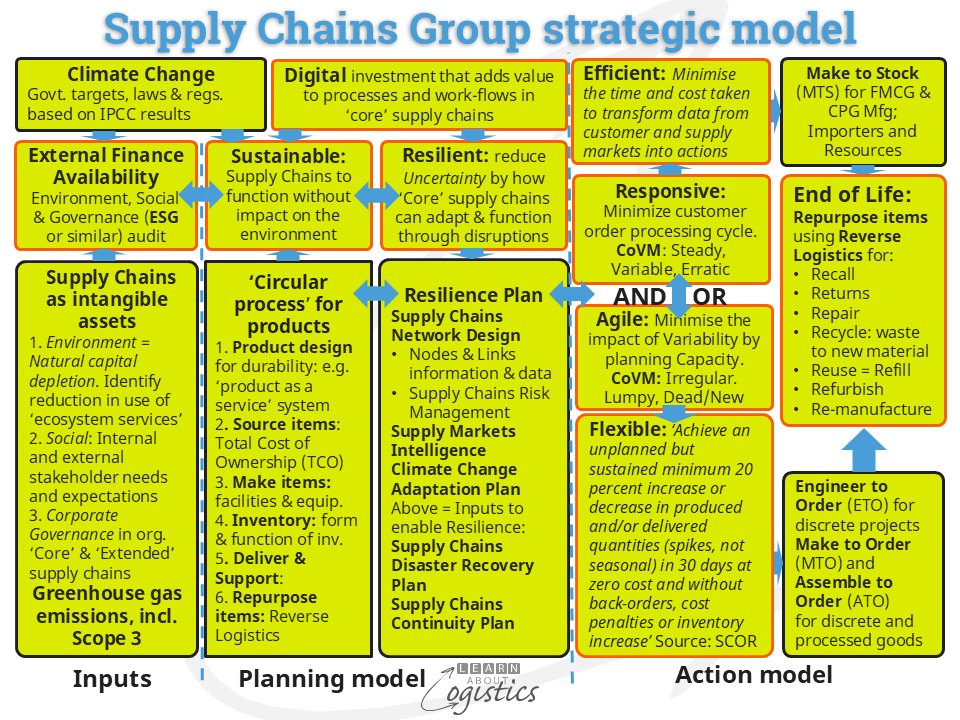

Learn About Logistics has developed a model that incorporates these additional aspects, as shown in the diagram below. The model is designed to define thinking and decisions at the strategic level. Each of the three sections can be expanded to identify the decisions required at the tactical and operational levels. Each level can be modified to suit your organisation’s requirements, so the model for your business can be different from the model used by competitors in the same industry.

To drive change and champion successes using this model will take time and require support from the senior management team. The model should be applicable until the end of the decade, by when the impact of climate change will be such that an updated model is required.

Sections in the model

The Learn About Logistics diagram identifies three sections in the model:

Section 1 Action model: are the factors required for the Supply Chains group to provide Availability of goods and services for customers and how DIFOTA will be achieved. A business can supply customers from either an inventory of finished goods or customers contact the business with a question similar to “how much will my order cost and when will I get it”? The first requires a business to be Responsive in supplying the order, through having a short order processing cycle. The second requires a business to be Agile through planning capacity.

Responsive and Agile style operations contain different outbound supply chains (the CoVM), so businesses that engage in both should separate them when past the initial materials processing stage. Also in this section are the options available at the end of a product’s life to enable a ‘circular economy’.

Supply chains will be defined by how they respond to various types of disruption and consequences that are unknown. Reacting to each disruption through central planning and control will become less of an option. Instead, a more decentralised and flexible response mechanism is required. Core supply chains, operational locations and workplaces should be enabled for decentralised planning and scheduling. This must include access to current data and information and risk and scenario analysis.

Section 2 Planning model: considers the requirements for continuance of an organisation’s supply chain operations, given disruptions caused by geopolitics, climate change and nature. Continuance requires enterprises working towards being a part of the ‘circular economy’ – meeting people’s needs by designing out waste from the process of product design, make and deliver (including return).

Being Sustainable and Resilient are corporate wide requirements, assisted by Digitalisation, each of which contain critical roles for the Supply Chains group.

Digital is the investment to convert work processes into digital flows through supply chains, which require interoperability (but not integration) between applications.

The Supply Chains Resilience Plan is based on risk avoidance and prevention and applied to ‘core’ supply chains (a business and its tier 1 suppliers and customers) to assure continuity of operations when exposed to major market, industry or supplier disruptions. Major disruptions can be be multiple and cumulative, therefore consideration must be given to the potential scope and possible interconnections of disruptions.

The Resilience Plan is used to construct the Supply Chains Disaster Recovery Plan and Supply Chains Continuity Plan. These identify the capability and processes required for the immediate response and short-term actions to recover from and then continue supply chain operations, following a major disruption.

The diagram identifies the Supply Chains Network Design (also called the Supply Chains Map) as the depositary of all information, including a risk analysis, that concerns inventory Nodes and transport Links of inbound and outbound supply chains in the network. The Map is the basis for constructing the strategy plan of each discipline in the Supply Chains group – Procurement, Operations Planning and Logistics.

Section 3 Inputs: availability of corporate finance, including trade finance, working capital and insurance will become increasingly dependent on compliance audits against ESG (environment, social and governance) laws and regulations, or equivalents that may be introduced. Supply chain professionals must consider the Adaptation required (monitor, identify, address and remedy) to address changing climate risks in their organisation’s core and extended supply chains.

Legislation will influence the supply chain relationship between large and medium size international businesses and their Tier 1 suppliers. For example, the recently introduced Corporate Sustainability Due Diligence Directive (CSDDD) by the European Union (EU) requires companies (including non-EU businesses with operations in the EU) to identify risks in their global supply chains. The CSDDD means that Tier 1 supplier contracts will need to contain clauses relating to compliance with the applicable legislation. In turn, the Tier 1 suppliers are likely to require their tier 1 suppliers to comply, or risk losing the contract.

Developing a supply chains model that reflects the needs of your business is a good initiative for member disciplines of the Supply Chains group, whether or not the group is formally structured. It provides the basis for the rational development of strategies that interface with the Business Plan.