Managing S&OP

A recent blogpost by Lora Cecere at Supply Chain Insights, identified reasons for companies failing to gain benefits from Sales & Operations Planning (S&OP). The main challenge is a lack of leadership to manage change in organisational culture. that recognises, plans and measures the business in an environment of flows within a complex, non-linear system.

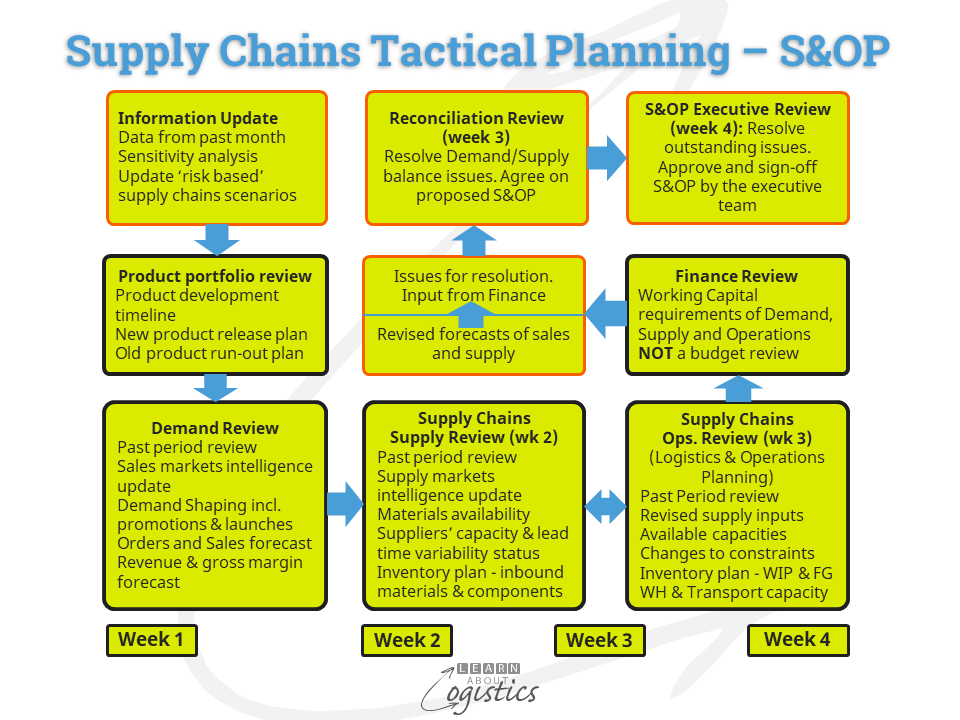

However, it is difficult for a senior manager to provide leadership for change when not understanding the process which they need to lead. Naturally, they expect their supply chain group executives and managers in Procurement, Operations Planning and Logistics to provide that knowledge, outlined in the diagram below. While S&OP is addressed in the APICS CPIM program, it is lacking within the curriculum at many university business schools.

Participants in S&OP

The Strategic Business Unit (SBU) manager, responsible for the P&L of a division, country, state/province etc., is a critical part of S&OP. It is they who lead the process and therefore need to be confident of what is involved, as implementation of S&OP will enable a change in the organisation culture towards more collaboration.

Participants in the S&OP process are:

- Sales’: the groups and departments on the demand side of an enterprise. Includes: Sales, Marketing, Product Development and Demand Planning

- ‘Operations’: the functions that work to supply products and services for sale. Includes Procurement, Operations Planning and Logistics (the supply chain group); Manufacturing/Production and Technical/Engineering

- Finance managers and executives attend the Reconciliation Review and S&OP Executive meetings. Prior to the meetings, Finance evaluates the proposed plans for effect on working capital, cash flow and profitability

- Managers and executives from the IT and HR/Personnel functions attend the Reconciliation Review and S&OP Executive meetings to provide inputs concerning resources availability over the S&OP period

Because S&OP is the tactical planning process for an organisation’s supply chains, the executive responsible for Supply Chains has responsibility for guiding the process. The Senior Planner in the SBU (who understands the planning process and knows how to structure and drive spreadsheets) is responsible for facilitating the review process and reconciling the completion of each review step.

S&OP Policy and other documents

SBUs and divisions should have a common approach to their S&OP. This includes a common definition for elements within demand, supply and planning. To ensure there is one approach to the process, the SBU manager must write the S&OP Policy document for all involved. This will:

- provide an overview of the process and its objectives. It emphasises that S&OP is NOT a strategic business plan; an operations review, or a budget review

- Identify the relationships of SBUs/Divisions within the enterprise and responsibility for availability of resources. For example: global planning authority with region responsibility; matrix organisation of local operations and region/global services) etc.

- identify the participants in the process and their responsibilities e.g. responsible; accountable; consulted or informed;

- explain the expected outcomes from each step through the S&OP cycle and

- provide the review meeting dates and times over the next 12 months

In the Policy document, it is essential that the SBU manager sets expectations. The initial implementation of S&OP will not achieve all that is possible; it will take time to be accepted, so expect at least a six month familiarity period.

Initially, S&OP is likely to rely on Excel spreadsheets, email, PowerPoint slides and data from your organisation’s ERP system. Their limitations must be explained and accepted, such as spreadsheets unable to do multiple ‘what-if’ scenarios and emails not designed for collaborative workflow and exception messaging.

S&OP is not a ‘software driven’ process, so overcome the misconception that specialist planning and analysis software is required for it to happen. As your organisation implements S&OP, the participants will progressively define the Supply Network Analysis and Planning (SNAP) software application requirements to answer ‘what if’ questions and build scenarios.

Structures within the Process

For ease of understanding the numbers, a standard unit of measure is used for both ‘Sales’ and ‘Operations’. This could be an equivalent to the ‘standard’ shipper (the carton size shipped to customers), tonnes, litres, pallets, hours etc.

Using ‘families’ of stock keeping units (SKUs) within S&OP provides consistency of communication across functions and entities. Because output governs what a business can sell, product ‘families’ are structured on each stock keeping unit (SKU) use of common resources. In some circumstances, ‘families’ may reflect the few brands or models that are supplied to major customers, such as when supplying to automotive assemblers. The number of ‘families’ varies between 5 and 15 (preferably in a range of between 6 and12).

Review meetings

The S&OP process cycle is typically monthly. However, to obtain consistency of input and output measurements, consider using 13 x 4 week periods per year. The S&OP process provides tactical planning over a future period of between month 3 and month18 or even month 24. The ‘freeze period’ is not considered in S&OP, where (say) the current and next month operational level plans are fixed and can only be changed with executive authorisation.

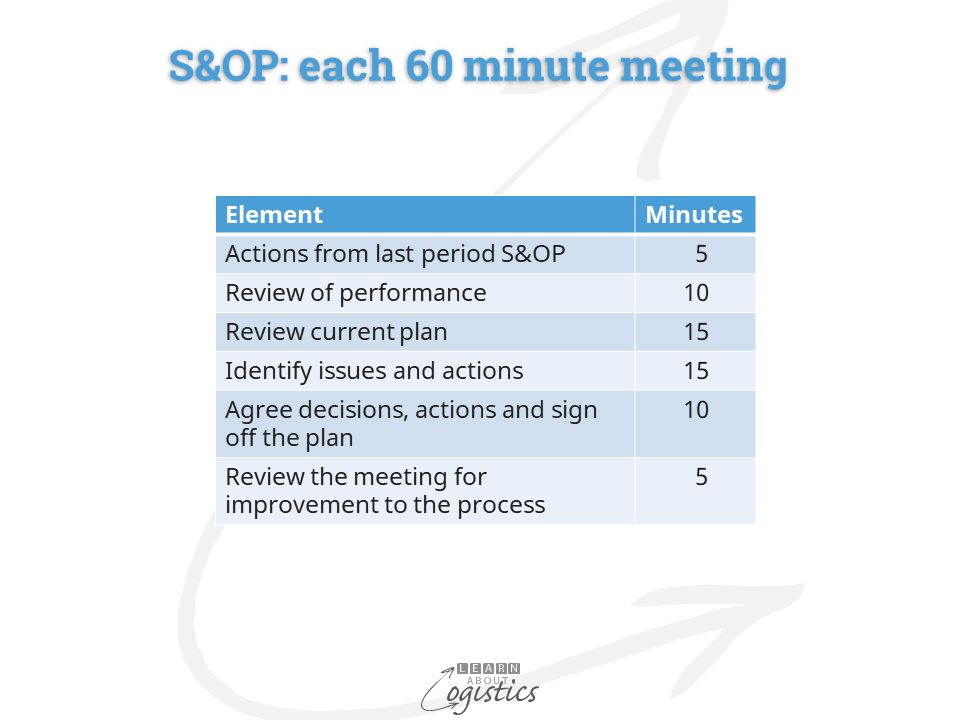

Each review meeting in the period will last one hour, although it may take the first three meetings with a strong chairman for participants to understand this rule. The structure of each meeting is to spend minimal time on reviewing the past, to allow discussion about the future. An outline meeting structure is:

The first diagram above is a guide which illustrates that prior to the S&OP Executive meeting, there is a progressive review process across Sales and Operations. The process commences with the Information Update that was discussed in the previous blogpost.

At the Demand Review, sales forecasts for each product family are provided for monthly intervals at months 3 to 6; quarterly for months 7 to 12 and half yearly for year 2, summarised by market segment/territory. Sales forecasts should be a ‘weighted forecast’ – provide a probability for the optimistic and pessimistic forecasts to arrive at a usable forecast. Actual sales can then have an expected variance of (say) +/- 5 percent error from the weighted forecast.

The Operations Review requires each SKU identified in the Bill of Materials (BOM) to ‘roll-up’ from the ERP system to their S&OP ‘family’. When reviewing Availability, consider the three elements – lead times, capacity and inventory as interconnected. Inventory is defined by form and function for each ‘family’ at nodes in the supply network.

At the Reconciliation review and S&OP Executive meetings, the chairperson needs to ensure that a balance is maintained between the inputs by ‘Sales’ and ‘Operations’ and other functions (especially Finance), as they learn how collaboration happens.

The Reconciliation Review is attended by a direct report to each of the S&OP Executive team members. The Reconciliation Review allows for plans, trade-offs and issues from each of the review meetings to be modified, accepted and packaged for the S&OP Executive meeting. It includes comments from Finance concerning revenues, working capital and cash flow, based on the period’s Sales and Operations review meetings.

The S&OP Executive meeting is for the senior management team to attend, as a part of each executive’s performance measure. If the Profit & Loss (P&L) responsible manager is unable to chair the meeting, it is rescheduled. No substitutes are allowed, as it can become a habit and the S&OP implementation will fail through a lack of commitment.

As the focus and needs of functions differ, the chairperson must ensure a balance between the opinions of executives. The objective is for the executive team to approve an achievable S&OP; taking collective responsibility to rectify major variances against the plan. This reduces the ‘finger pointing’ and recriminations when supply chain activities are planned in silos.

S&OP for supply chains

The updated S&OP by each ‘family’ is an input to the Supply & Operation Execution (S&OE) process. This commences with the approved S&OP for the longest lead time of purchased materials converted to SKUs for the Master Schedule (or similar term) in the ERP system. The Master Schedule is the driver for plans concerning inbound supplied items, production and delivery plans and schedules.

To reduce uncertainty and improve visibility in supply chains, the ideal situation is for your organisation’s Master Schedule to become an input to the S&OP process at Tier 1 suppliers – those suppliers then do the same for their suppliers. And that makes for a successful S&OP implementation!