COP28 climate conference

The meeting in Dubai has concluded, and the limited outcomes are unlikely to make a substantial difference to the expected climate change for the planet. The current emphasis on Mitigation through decarbonising supply chains is insufficient. It will therefore also require Adaptation (or resilience), to protect citizens and organisations against an adverse climate.

However, because Climate Change has been a slowly emerging crisis, many parties have ‘kicked the can down the road’, to the next generation. As business surveys indicate, resilience as a strategic approach has yet to be broadly accepted and adopted. And this situation could continue until, like the 2008 global financial crisis and the Covid19 pandemic, there is a self-evident crisis that must be fixed at any price – it then may be too late.

Challenge for supply chains

Climate Change is cumulative. What was expected in 2030 has happened in 2023 and the 2050 target for ‘net zero’ emissions should occur in 2040 (or earlier). Uncertainty will therefore exist in the global economy, making it more difficult to know how suppliers, customers and consumers will respond to events. This will add to an unknown financial impact on economies and businesses, that will force change throughout the supply chains.

The current functioning of societies is built on the assumption of a stable climate. Therefore, to guard against major disruptions, significant investments must be taken by governments and businesses over a relatively short period, as socio-economic systems adapt to the ‘new normal’.

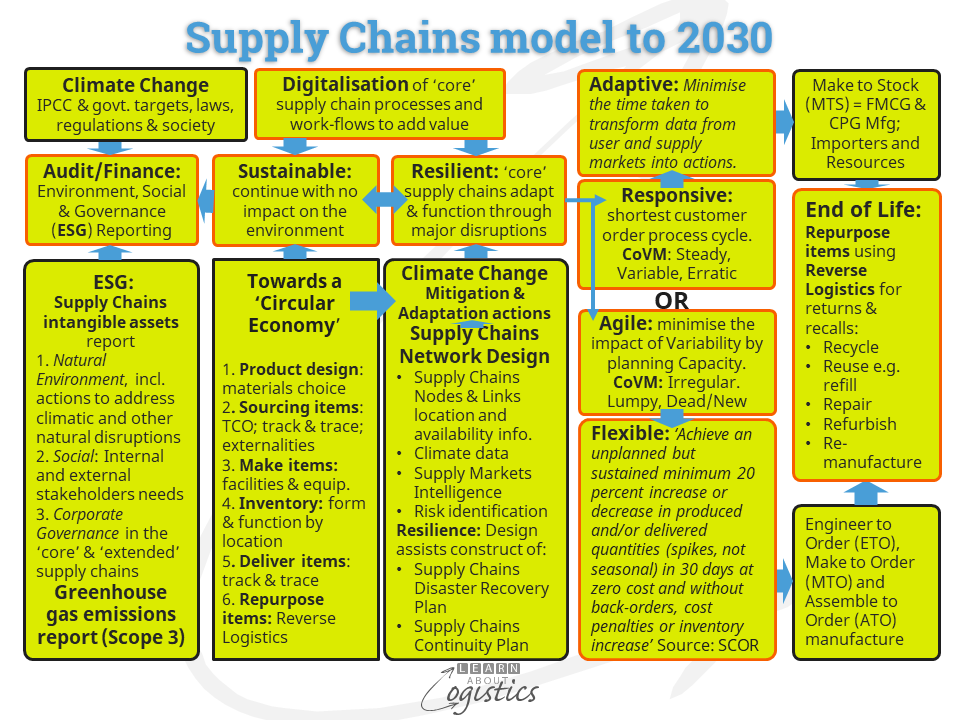

Also, Supply chain professionals must consider macroeconomic factors, such as the influence of country specific risks and structural change within industries, in the design of their organisation’s supply chains. This will result in an increased focus on risk analysis and the gathering of relevant intelligence, to structure a range of possible outcomes and contingency plans. The LAL Supply Chains model for the remainder of this decade is shown in the updated diagram.

Implement Adaptation

Actions under Mitigation are to eliminate carbon emissions through the ‘core’ supply chains and assist in their reduction through the ‘extended’ supply chains. Adaptation actions are to allow an organisation’s Operations to adapt to the impact of climate change that has occurred and to prepare against the expectations of future change. The pre-requisites identified by consultants McKinsey for implementing Adaptation actions are:

- Risk management approach: build an understanding of existing risks and how they are expected to evolve. Set climate risk preferences and tolerances, aided by data and information needed to support decision-making

- Technical and behaviour adaptation: identify and implement technical and behaviour solutions

- Economic and societal adjustments: identify and acquire the finance required to deploy Adaptation solutions. Recognise and price climate change risks. Structure support for employees, individuals and communities most vulnerable to the risks

- Governance, institutional support, and commitment: develop awareness and policies that enable employee and community support for adaptation to climate change

To build Adaptation into its supply chains strategy, a business needs to rethink the physical operations model: where they operate, their supply footprint, the materials they source and the suppliers. The primary consideration through an organisation’s supply chains will be the physical risk to buildings and production, warehouse and transport operations. These are owned or leased by the organisation, 3PLs and other logistics services businesses, contract manufacturers and suppliers. Information concerning these assets and climate data for each location is held in the Supply Chains Network Design, (see model) to inform decisions about supply and Adaptation actions. Investments in Adaptation can include:

- relocating buildings to areas with a lower risk profile

- fortifying current physical assets e.g. raising electrical equipment above potential flood depth

- installing solar technologies to generate sufficient power for Logistics Operations

- using low energy technologies to improve working conditions and/or to protect products

- changes to working hours in cooler times of the day for employees and contractors that may require decisions about personal transport arrangements

- planting trees around buildings to provide shade

- monitoring climate hazards (heat, rain and wind) and deploying emergency equipment

- buying decisions concerning location

- inventory decisions concerning products; seasonal inventory and form & function of inventory by location

- distribution decisions about delivery hours to customer locations and the additional costs of night deliveries

In addition, is the potential trade-off concerning investment in Adaptation against the building insurance cover provided. In some locations, insurance companies are declining to provide cover due to high risk, such as buildings constructed on a floodplain.

Risk Assessment

As information is gathered, a ‘risk assessment’ is done. The physical risks are translated (initially as a rough estimate) into ‘business value at risk’ across a set of expected scenarios. In addition to the value of direct damage to buildings and other assets, will be the potential value lost by businesses, communities and the natural environment through and across the supply chains.

Because a business cannot guard against all eventualities, the ‘risk tolerance’ for each type of risk must be identified. The Supply Chains group must identify and justify the acceptable level of risk by type over an identified timeframe. For example, as a climate emergency unfolds, authorities too often say that it is a ‘one in one hundred year’ event. This statement should read as a ‘one percent chance of the event occurring every year’. What would be the reaction if the risk level was increased to a ten percent chance of the event occurring every year?

The risk tolerance will guide your organisation’s willingness to invest in Adaptation. Given the need to invest in climate mitigation, building and equipment upgrades and maintenance, executives must decide where, when and to what financial level Adaptation actions should occur.

Adaptation Plan

The selection and implementation plan for Adaptation will have a long timeline, as building works, equipment purchases and technology installation can each have long lead times. The Plan will identify the extent of Climate Change that is expected and the risk preferences by type of climate risk. Responsibility for Adaptation decisions, expenditure and implementation are also identified.

While your organisation can decide to ‘kick the can down the road’, there will come a time when action in the supply chains is required. One of the outcomes from COP28 is that nearly 130 countries have agreed that by 2030 they will triple renewable energy generation capacity and double energy efficiency across their economies. Over the next six years all these countries will be bidding for the same materials and skills, so it is preferable for your business to get in early and adapt to the future that will happen.

Dear Reader. It is summer holiday time in Australia. The LAL blogposts will return on Monday January 15, 2024. We hope that reading the blogposts has sparked some ideas for improving your supply chains. Have a good and safe 2024.