Suitable solutions in Planning

Because an organisation’s relationships within its supply chains differ to those of other businesses, it is not advisable to promote a single solution for a situation in supply chains. However, there are various approaches that supply chain professionals should have that enables the most suitable solution to be identified.

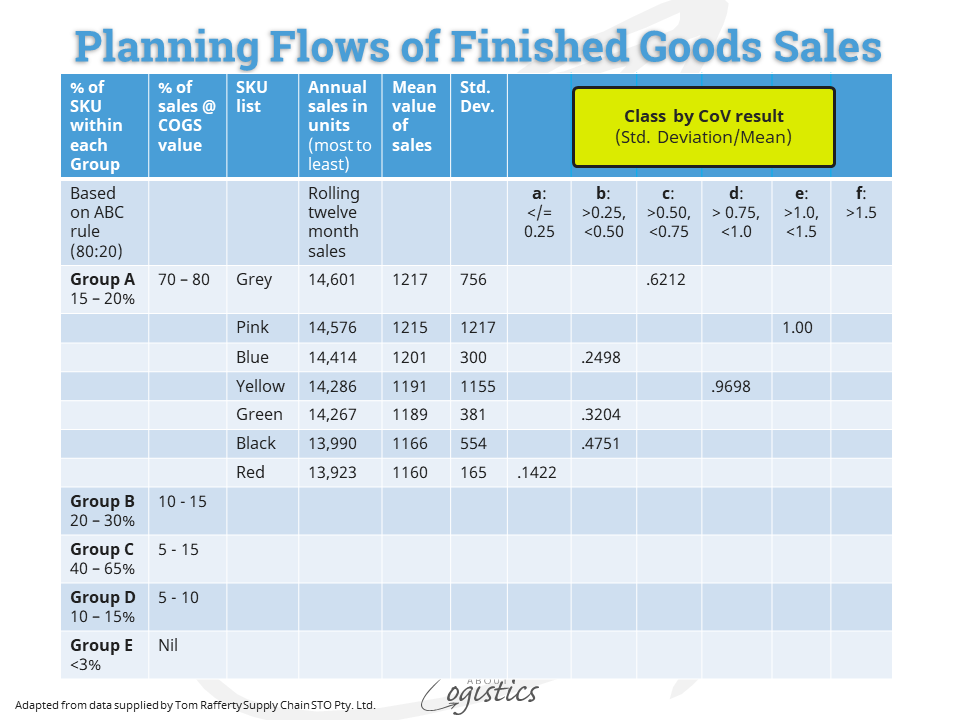

To provide some background to the selection of planning options, the previous blogpost discussed Demand Amplification (the Bullwhip effect) and its relation to different types of supply chains. Using the Coefficient of Variance (CoV) of sales provides a basis for allocating stock keeping units (SKUs) to a Class within its sales Group (A to F).

With SKUs in each Group allocated to their CoV Class, all SKUs in the same Class are collated for action. For example, in Group A (the Group containing 15-20 percent of SKUs and 70-80 percent of sales value), there will be Group/Class of Aa, Ab, Ac, Ad, Ae and Af. The same process occurs for Groups B to F.

All the Class ‘a’ to ‘f’ are now identified. Each Class represents an outbound supply chain. In addition, the CoV calculated supply chains can be modified or to make additional supply chains, due to product or customer requirements:

- Customers with specific requirements concerning their defined SKUs, for example vehicle assemblers, pharmaceutical companies or supermarket chains

- Finished goods produced for the enterprise in defined countries and locations and using the same modes of transport. These items can be consolidated into containers to reduce transport costs

- Volume to Weight and Value to Weight ratios of SKUs, as the ratios can influence the selection of distribution methods and transport modes

- Risks associated with the item: contamination; perishable; ageing (use by date); flammable/explosive; and theft

- SKUs that utilise a Constraint in the business, which restricts output and therefore potential sales. A Constraint can include specific equipment or access to materials, either obtained on a seasonal basis or deemed to be ‘critical’

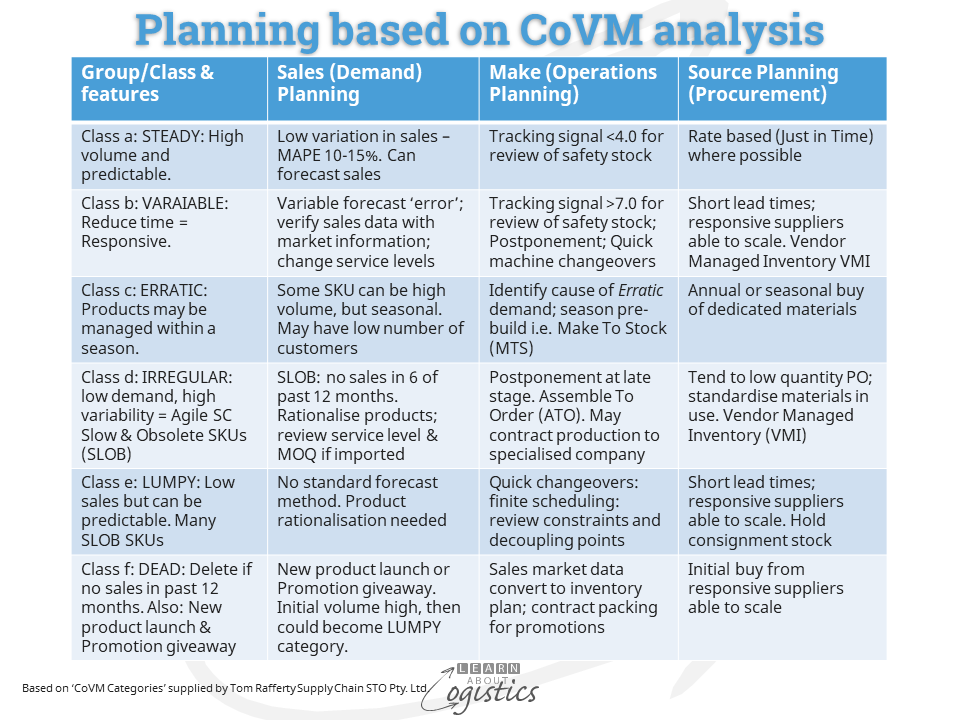

Each Class or supply chain has a management descriptor as shown in the left column of the diagram below.

- Class ‘a’ = Steady: Often represents 20-30% of total sales. The flow of orders is predictable and high volume

- Class ‘b’ = Variable: The objective in this supply chain is not to be efficient, but to reduce cycle times

- Class ‘c’ = Erratic: Typically, seasonal products managed within a season or pre-builds prior to a seasonal high demand e.g. confectionery

- Class ‘d’ = Irregular: Low demand with high variability of demand, such as fashion items and maintenance parts

- Class ‘e’ = Lumpy: Low demand but can be predictable. Many slow & obsolete (SLOB) SKUs

- Class ‘f’ = Dead: Delete SKUs from the sales catalogue if no sales in prior 12 months. Also includes new product launch and promotional giveaway, which following high volume at release can then become Class ‘e’ – Lumpy

Given these management descriptors and explanation, the style of managing the flows can be identified. For Class ‘a’, ‘b’ and ‘c’, the objective is to achieve the shortest customer order process cycle. This requires the business to minimise the time taken to transform data from user and supply markets into actions – that is to be Adaptable.

However, because Class ‘a’ is rated as Steady, with predictable and high volume orders, the aim of this supply chain is to be Efficient. For Class ‘b’ and ‘c’, the volume of orders is Variable or Erratic, therefore the aim is to be Responsive. The focus for the structure and Operations Planning of Steady, Variable and Erratic is Make to Stock (MTS).

For Class ‘d’, ‘e’ and ‘f’, the objective is to be Flexible and therefore able to quickly increase and reduce throughput in the supply chains. As these supply chains have Variable sales inputs, the aim is to reduce Variability through effective planning of Capacity. Depending on the business and its products, the focus for the structure and Operations Planning is either Engineer to Order (ETO), Make to Order (MTO) – the modification of pre-designed products, or Assemble to Order (ATO).

For each Operations Planning focus, the Procurement planning and Logistics operations will differ. This indicates that the ideal outcome for supply chains is not high efficiency, but to be most effective in serving the range of customers. That is to have a high probability of DIFOTA – delivery in full, on time, with accuracy, coupled with other Supply Chains group performance measures of: operating margin, inventory turns and Return on Invested Capital for supply chains (ROIC-SC).

Effective supply chains

The methodology described in this blogpost will not be implemented without the approval of senior management. To identify your organisation’s multiple supply chains, then structure the planning process so that supply chains become effective requires an understanding of the underpinnings to make to new approach successful:

- So that all connected with the supply chains are singing from the same page, bring the teams from Procurement, Operations Planning and Logistics together within a Supply Chains group

- A focus of the Supply Chains group must be on the accuracy of your organisation’s data. Without confidence in the data, the planning teams cannot produce plans in which management has confidence. Concurrently, review the value of using additional data elements that exist in the business, but are not used.

- Understand how the organisation’s supply chains function and interact through supplier and transport networks. Identify inventory buffer strategies and push/pull decoupling points. Build the Supply Chains Network Design Map. With the current state of knowledge, there will initially be many blank spaces and lack of detail, so the process is an ongoing project.

- Establish the process whereby Marketing and Sales, Finance and the Supply Chains group can build cross-function collaboration to align the business. The process is Sales & Operations Planning (S&OP). S&OP is a tactical process that helps an organisation make effective trade-offs between the Demand and Supply Plans. The output is an agreed Plan that positions internal and external resources (items, people, equipment and suppliers) to provide Availability of products for customers through the effective movement and storage of items.

Too many companies manage their supply chains based on an assumed single flow, using the attainment of efficiencies to guide the planning process. A company that has a focus on the performance of functions like distribution and production, through measuring individual metrics such as inventory or operational costs, cannot be an effective business.