AI deliverables

By mid-2023, there were at least 50 start-up companies in the US, rated by Forbes magazine as the most promising in development of AI technologies. There are also several promising AI start-ups in other countries. If there are promising start-ups, there must also be those that are less promising, so watch out for dubious ‘blue sky’ promises about AI in your business.

Large multinational branded goods companies and international providers of logistics services have access to resources that enable their own AI based systems to be built. Some will fail, with high costs, but these companies can afford the learning errors. For the majority of businesses, the risks are too high to ‘build your own’.

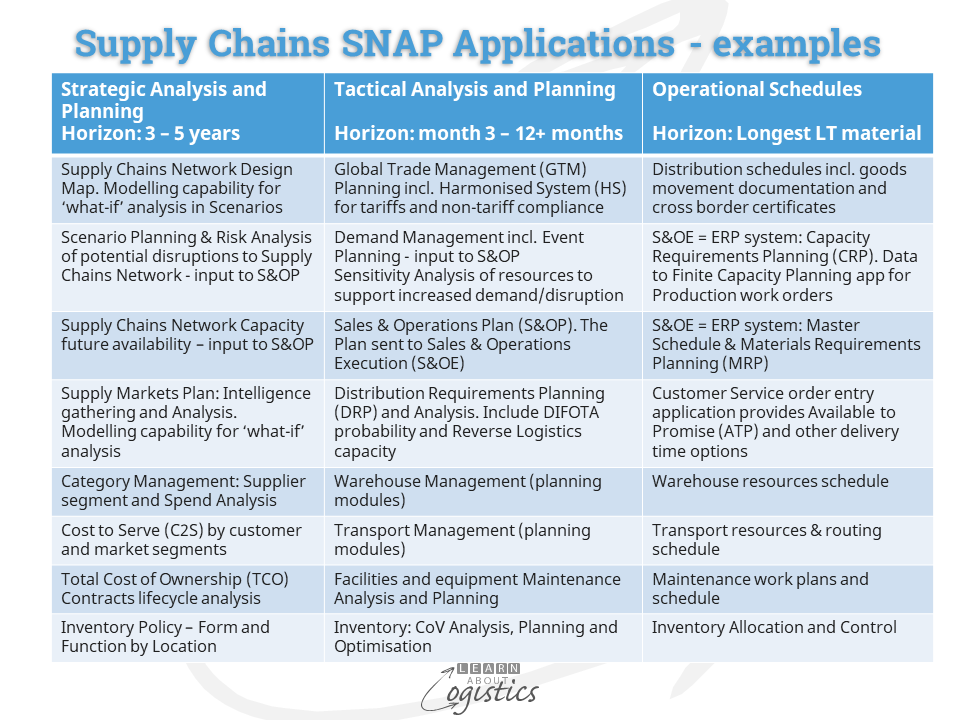

For many enterprises, it is more likely that an AI capability will be embedded in the Supply Network Analysis and Planning (SNAP) applications shown in the diagram. This is called Artificial ‘narrow’ or ‘domain’ intelligence, which requires a system to learn from a restricted range of data (typically internal). It differs from the much hyped Artificial ‘general’ intelligence, which uses all the data (including images and voice) that can be scraped from existing sources to learn.

The focus of AI in these application areas will most likely be on two capabilities:

Pattern Recognition – the analysis of data to detect patterns. This is a sub-set of Machine Learning (ML), which uses historical data to learn and teach a computer based algorithm the patterns experienced. The algorithm is then enabled to make predictions and recommendations (and maybe decisions).

Analytics provide insights about data that might not otherwise be detected and which enables more informed decisions to be made. There are three types of Analytics:

- Descriptive Analytics uses statistical techniques to summarize and describe a set of data, identifying trends and relationships

- Predictive Analytics use probability theories to determine what is likely to happen, based on patterns and trends revealed from analysing large sets of historical and/or real-time data

- Prescriptive Analytics use the results provided by predictive analytics to determine the best action plans for achieving a desired outcome

The Tactical planning level (Sales & Operations Planning) is where AI capabilities can initially best be used for supply chains, as it can be in a controlled and secure environment with relatively few participants:

- recommend plans for different time horizons. AI should not be expected to provide the perfect plan; instead it proposes options and provides evidence

- incorporates uncertainty (what-if) into simulations to help evaluate scenarios and identify risks

- recommend operational decisions with margins and risks. Reducing costs does not necessarily improve margins

- provide visibility that anticipates supply chain disruptions. An AI tool needs to know the demand, distribution and supply situations and the relevant constraints and capacities in each supply chain

Initially, it is preferable that the AI tools do not make decisions, which is the role of people. However, the planning team must be trained not to automatically accept what the system says – that is ‘autonomation’ bias.

Later, AI systems could also help to improve Operational level activities, such as: demand forecasting, transport and freight management, purchase orders and invoice control. Also in compliance and records handling. At the Execution level, machine maintenance planning and scheduling can be improved using AI systems.

When an AI enabled application is available

As always, the main challenge of selecting software applications is not technical. Instead, it is an understanding of your organisation’s business challenges and capabilities and how the application will address them. Do not assume that AI will solve the complexities in your organisation’s supply chains. If you cannot analyse the problem using supply chain principles, AI is unlikely to provide the solution.

When an applications software supplier announces an AI application, check the status of your organisation’s data. To train an algorithm in a machine learning AI system requires that data for learning must be identified, accessed, collected, processed, and evaluated in a structured sequence of steps. But before this step, answer the following questions:

- Does your company undertake an ongoing (say monthly) audit of the supply chains data? If there is an audit, does the report provide either an ‘excellent’ (98 percent) or ‘good’ (95 percent) rating? If not, the data cannot be used for training an AI enabled system – remember ‘garbage in, garbage out’.

- Is there a process to remove the RROT of redundant, repetitive, obsolete and trivial data?

- How will clean, accurate and timely input data be assured? This addresses missing, not considered, inaccurate and mismatched data from sources not controlled by Operations Planning?

- How will mistakes and bias in the algorithm be identified? This is because as AI updates the data and learns, the initial algorithm becomes difficult to recover, therefore humans are less able to identify the root cause of failures and bias in algorithms.

- How will the performance of an algorithm be measured over time as it uses the new data?

- Proponents of AI solutions emphasise decisions in real-time, but is that required? Re-planning and changing execution plans in real time creates nervousness across the physical operations. Sales & Operations Planning is currently at monthly or four week intervals and looks forward beyond the freeze period. Would real time S&OP be a benefit?

- The system may be required to process large volumes of data at short notice. Is the Supply Chains group able to fund large cloud computing facilities?

Without the answers to these questions, it is an unwise decision to proceed. But all is not lost; concurrent with the activities to evaluate AI based applications, you can work to simplify the planning of your organisation’s supply chains. Have as your ongoing emphasis, the business relationships, your people, workflows and processes, and then AI.

2 Comments on “AI built into future supply chain software applications”

As usual Roger, brilliant, insightful and extremely relevant for today’s operational environment.

Thankyou Ian for the positive feedback. It is good to know that a blogpost has relevance.