Corporate and Supply Chain Scenarios

The previous blogpost discussed Scenario Planning at the corporate level, with four scenarios having the most potential over the next five years. The referenced article provides possible actions at the strategic level, with a focus on economic, business and finance. Depending on the culture and structure of the organisation, there are two options for the Supply Chains group (Procurement, Operations Planning and Logistics):

- Based on the actions identified at the strategic level, specify in greater detail the potential actions at the tactical and operational levels

- Because supply chain scenarios reflect operational concerns, undertake Scenario Analysis (or thinking) and Planning for the next ten years.

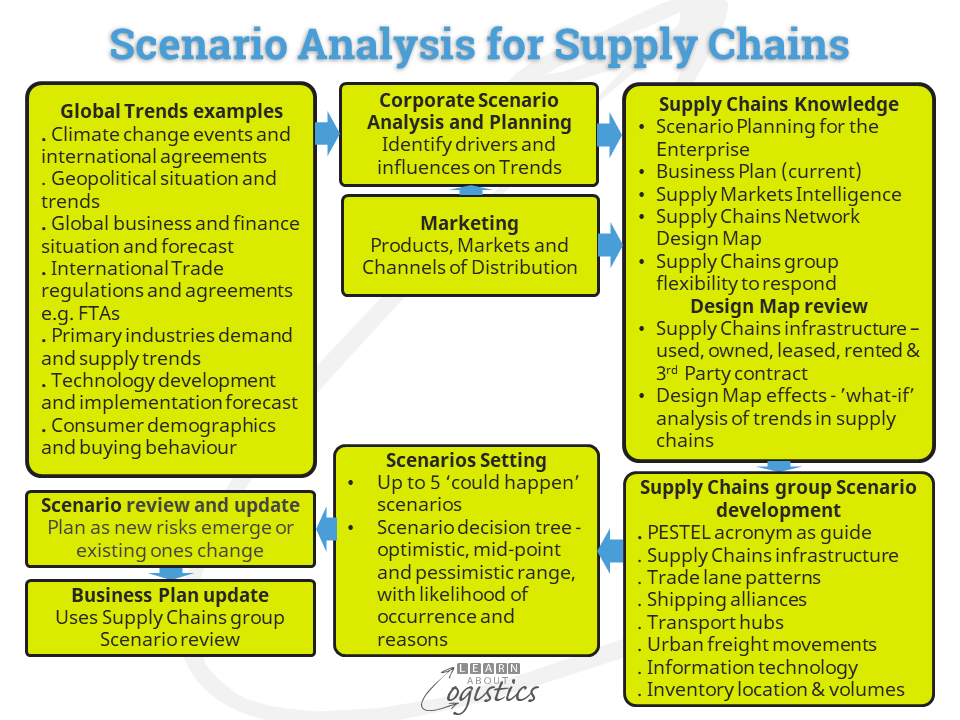

The Scenario process for supply chains is shown in the diagram.

Scenario Thinking or Analysis

Scenario Thinking is to be prepared. It involves gathering data and information, analysing possible disruptions, trends and triggers, describing possible scenarios, and enabling quick input to update responses to events.

This process requires a team consisting of people from each discipline within the Supply Chains group, plus others with wide experiences from across the business and ideally facilitated by a person from outside the business.

An important reference document used in the process is the Supply Chains Network Design Map, which describes each Node and Link through the organisation’s supply chains, together with supporting data. While the Map may not be complete in all details, it does require sufficient data and information of the Core supply chains, between Tier 1 customers, the organisation and Tier 1 suppliers. An addendum to the Map identifies the organisation’s main supply chain vulnerabilities, such as:

External resources

- logistics services providers (LSP) and contract manufacturers

- reliance on hub ports and logistics hubs for the movement and storage of items

- critical material items supply; concentration of suppliers; materials price fluctuations and trends

- capability to on-shore or near-shore production and implement reverse logistics

Internal capability

- capability to insource production and/or distribution elements;

- capability concerning supply chains technology: specify requirements, selection and implementation

- supply chains skills, location and availability

- organisation structure – domestic, regional and international

Information and data

- actual visibility through individual supply chains

- extent of data, information and knowledge sharing with external parties

Due to varying probabilities of infrastructure not being available following a major disruption, the Map ideally requires current information concerning the location of each inventory Node and transport Link through the organisation’s supply chains. This includes the location of infrastructure that is used, such as ports; also premises that are owned, leased and rented at customers, suppliers, logistics services, transport providers, contract manufacturers and the organisation’s facilities.

How vulnerable are they? What is the expected Time to Recover (TTR) if critical inventory Nodes or transport Links become unavailable? What are the alternatives available? Then consider:

- the inventory form and function required at location Nodes, to addresses needs of the business when supplies are limited

- IT and communication potential failures and risk of cyber security attack through the organisation’s supply chains

Trends in global supply chains

With the Supply Chains Map as the reference document, the team considers the forces that are or will drive systemic changes that are likely to transform or strongly influence supply chains, noting that:

- Global trends and influences through supply chains are both independent and inter-dependent

- Given current uncertainty, challenge assumptions and consider unthinkable disruptions – they only need to be plausible, because being ‘realistic’ depends on an individual’s opinions

- Consider events that are beyond your organisation’s control and influence

The time horizon to consider must be sufficiently long to avoid just doing a risk analysis of the present, but sufficiently short for scenarios to have relevance. About 10 years into the future appears to be sufficient. Because supply chains cut across many domains, as a guide use an acronym such as PESTEL -(geo)-Political, Economic, Social, Technology, Environment and Legal. Relevant supply chain trends to consider are:

- Changing trade lanes e.g. Growth of the land-bridge between China and Europe and India-Europe. Disruptions at ‘choke-points’ in trade lanes e.g. current disruption in Panama Canal

- Climate Change and potential significant damage to port and hinterland infrastructure

- Hub ports and increasing size of transport units

- Shipping alliances remain or dissolve

- Urban freight movement restrictions

- Inventory location and volume decisions – ‘just in case’ inventory caused by disruptive events (especially at tier 2 suppliers and below). Cost-effective technologies encourage local production of some items; result in reduced inventory, warehouse and transport

- Information technology – direct booking and ‘track & trace’ capability reduces need for facilitators through supply chains

When considering risks in an organisation’s Supply Chains Network Design Map, questions typically focus on risks aligned to Availability and Vulnerability. However, Complexity and Inter-relationships within supply chains also require consideration:

- Where among the Nodes and Links of the Network is Power exercised (through ownership, control or influence) and risks associated with Dependency between businesses. These may affect the response to a disruption (such as allocation of scarce materials).

- Cascading risks: impact of a disruption along and across the supply chains – disruption is unlikely to end at a defined place or link in a chain

- Contingent risks: events within a supplier’s business that could affect a supply chain e.g.

- fire at a material supplier or cargo theft from a 3PL

- concentration of assets along supply chains, such as at Hub Ports and Logistics Hubs

- licences to operate a commercial business that are issued (and can be withdrawn) by a national government

- Interdependent risks: events (e.g. shortage of a raw material) in one industry or company may affect demand and supply factors in other industry sector suppliers to your business, operating at Tiers 2, 3 or 4

- Emergent risks: developments that may change demand and supply in an industry sector, which supplies items into your organisation’s supply chains

Scenario Planning

Based on outputs from the ‘thinking’ process, the critical uncertainties can be identified – those that are potentially important and also very uncertain, which provide four or five supply chain key themes or scenarios. ‘What-if’ options are considered, such as: change inputs and outputs; expand, contract or postpone operations; terminate a project or operational direction; phase an implementation to conserve resources. Scenarios can also be compared using decision tree diagrams with options from optimistic to mid-point to pessimistic at each fork in the tree and applying the discounted cash flow (DCF) technique.

A scoping document is then developed that identifies possible mitigation actions for the current supply chains, such as: alternative suppliers and transport options and changing inventory policy. However, when a major event occurs, the critical factor is the capability of the Supply Chains group to respond.