Why Resilient Supply Chains?

Based on articles in the media, Resilience is now an expected capability across different industries. But what does being resilient mean and does the need apply equally across all businesses? And what steps should be taken to become resilient?

Globalisation came to the fore about thirty years ago, when many businesses in developed countries were intent on achieving low unit costs for products. This, combined with an attractive political and financial situation helped the establishment of off-shore production and supply chains for materials and intermediate goods.

The resultant supply chains became complex and less adaptable to increasing disruptions. Research in the early 2000s concerning the effects of disruptions for US businesses, identified that about every four to five years, many companies would face a crisis, including a major disruption to the business of 10 days and longer. Of the companies that experience a crisis, about 45 percent would never fully recover. With major disruptions increasing to about every 3.5 years and extending to a month or longer, there is an increasing urgency for businesses to recognise and act on the need to become more resilient

Supply chains adapt to new circumstances over time. However, in the short term, individual businesses within the chain need to respond to emerging results from a disruption without a clear understanding of the reasons for actions taken by all other organisations in the supply chain.

The LAL definition of resilient supply chain is ‘the ‘core’ supply chain (a business and its tier 1 suppliers and customers) continues to function when exposed to major market, industry or supplier disruptions and adapts to the changes to assure continuity’.

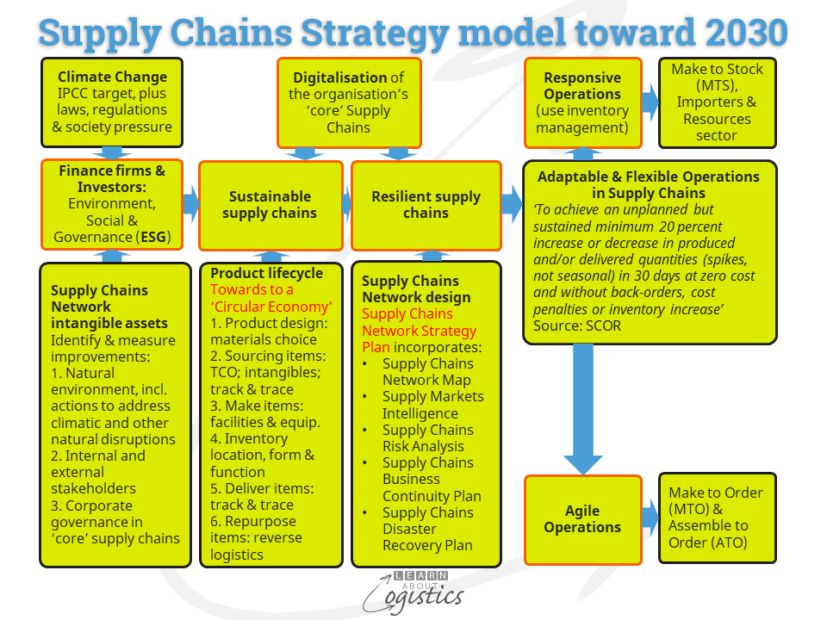

The diagram shows that Sustainable supply chains are derived from ESG reporting requirements. Resilient supply chains are the response of the supply chain group to the need for a business to survive and prosper in the face of major disruptions.

Vulnerabilities in supply chains

A major challenge for supply chain professionals is experiencing uncertainty about suitable responses to a disruption. Prior to the disruptions is the need to identify vulnerabilities in your organisation’s supply chains. Vulnerabilities are the specific factors that make a business more likely to experience major disruptions – they exist in both the supply and demand sides of supply chains. The broad headings and some examples of Vulnerabilities are:

- Geopolitical:

- Political tensions lead to imposition of import and export bans,

- tariff and non-tariff regulations;

- quantity quotas

- Environmental: Exposure to extreme weather events and health events (i.e. pandemics)

- Economic:

- An event that disrupts global supply chains (e.g. 2008 global financial crisis, 2020 COVID pandemic);

- Trade disputes between countries made worse for an organisation by the number of supplier tiers in the chain and intermediate items that cross many borders;;

- Most suppliers within a tier are located within a small geographical area (e.g. consumer electronics);

- A supply chain that relies on a single upstream supplier for a critical input item;

- A ‘unique dependency’ on a supplier

- Infrastructure:

- Dependent on IT services (e.g. potential for cyberattack);

- Electricity supply capabilities;

- Limited number of ports;

- Depends on a transport link in the chain that cannot be easily substituted (i.e. alternate sources of supply are readily available)

- Social: Labour availability (can be affected by environmental factors); human rights observance

Vulnerabilities are potential exposure to major disruptions in a supply market that is likely to affect all buyers accessing that market. They should be identified separately from the ongoing operational uncertainties (risks) in your supply chains.

Steps towards a Supply Chains Network Strategy Plan

To construct a Strategy Plan for Resilient supply chains, requires a structured approach to understand your organisation’s Supply Chains Network. This is an ongoing building of knowledge, so do not expect to have a completed ‘solution’ at the first pass.

The diagram above illustrates that building the information base incorporates a number of action documents that help to change Uncertainties into structured Risks – the five documents will be discussed in a future blogpost.

The Supply Chains Network Map provides a visual structure concerning the flows of items, money, data and information between the nodes (for suppliers) and links (for 3PLs and transport suppliers) along each supply chain. To develop resilient supply chains, the Map is used to translate unit volume and flow data into ‘what-if’ scenarios and analysis concerning the effects and possible protections on the gross margin.

Using the ‘work in progress’ information in the Supply Chains Network Map enables the second stage. This is to identify and quantify known and unknown risks in the supply chains. The objective is to establish a balance between the identified risks and the protections implemented to mitigate risks.

A factor about the identification, analysis and management of risks is that it is a process conducted by people who carry a wide range of biases concerning aspects of supply chains. These can influence the perception of risks:

- Incorrect assumptions about events and risks by people in the supply chain group can result in a misallocation of resources. This can be important for events that have a low likelihood of occurring, but with high consequences if it does

- Supply Chain Networks, as Complex Adaptable Systems exhibit ‘emergent’ responses and outcomes to events by suppliers and customers in a chain The risks to your organisation can be caused by events that could be considered as highly unlikely and therefore are not understood

- To reduce the complexity of analysis, each risk is usually identified and analysed independently of other risks. However, there can be interactions between parties in supply chains which may influence outcomes, but these are not recognised within the supply chains group

- The presumption of risk analysis is that current processes are the ‘normal’. However, potential disruptions can be a signal to make changes and improvements in the supply chains

With the Risk Analysis completed, the results can be applied to Scenario Planning, discussed in an earlier blogpost The analysis and discussions concerning the scenarios provides the inputs for notes about possible actions taken to address disruptions. These are not prescriptive documents; Resilience is the ability to adapt, using the capabilities of people in the organisation – highly prescriptive ‘solutions’ act against this.

As organisations become larger, they tend to be less adaptable, therefore less resilient. The larger and more complex your supply chains, the bigger challenge to generate a recognition that resilience is a need for the future. But climate change and its challenges will not go away, so it is organisations that will have to change.