Sales & Operations Planning developments

Even as ‘collaboration’ software is implemented, gaining power within organisation structures will continue. The increased importance of Supply Chains in the eyes of senior executives could result in the discipline become a target for takeover by Finance. And developments happening in Sales & Operations Planning (S&OP) lend support to the possibility.

The research firm Gartner recently identified the potential for what they call xP&A, where ‘x’ represents ‘connected and continuous’ Planning and Analytics. The firm considers this development will enable Finance to lead software based company planning and performance management; in particular S&OP. Gartner also notes that to support ‘mission critical’ decision making, Financial Planning & Analysis (FP&A) activities will include xP&A by 2024.

Whether that forecast is achieved does not matter, it is the intent that should be of concern to Supply Chain professionals. In many organisations, one part of supply chains – the department titled Procurement or Purchasing or Supply already reports to Finance. If S&OP becomes the responsibility of Finance, then the other two parts of supply chains – Operations Planning and Logistics will also report to Finance.

In addition, some consulting organisations are using the term Integrated Business Planning (IBP) in place of S&OP. This action has probably be done to enable the sale of consulting assignments at senior management level. However, by changing the name of the concept, it adds to any claims by Finance that they should be responsible for this ‘business process’.

For companies selling commercial software, a major step to a sale is gaining the support of Finance. Although S&OP as a concept has existed for the past 40 years years, its implementation has been slow, due in part to the misconception that specialist planning and analysis software is required. That software is now being progressively introduced and the easiest way to gain a sale is to demonstrate that the application has a direct benefit for Finance.

As an example, the website of an S&OP software supplier states “…financial performance for the previous month is consolidated to provide inputs for analysing the current month’s S&OP cycle. Finance owns this process and it can include different categories or views, including product, geography, customer and channel. Actual costs are compared with budgets and forecasts to analyse forecast accuracy over a rolling time frame”.

The previous paragraph goes against much that has been written and spoken about the S&OP process. Supply Chain professionals must make it clear in their organisation that S&OP is NOT a strategic business plan; an operations review, or a budget review. As it is a planning process, S&OP process must not be constrained by the current budget; however, outputs from S&OP can be used as an input for updates to the budget.

The S&OP process has value

The value of S&OP to your business is as a structured tactical process for planning supply chains over the medium term (typically in the range of 18-24 months), based on inputs concerned with demand and supply. S&OP is not a software driven process, although it will gain in its capability from the use of specialist software that assists with answering ‘what if’ questions and building scenarios. To really make S&OP effective in an organisation requires a concentration on the aspects of people and process. Those involved in the S&OP process are:

- ‘Sales’, which includes the groups and departments on the demand side of an enterprise. This includes: sales, marketing, product development and demand planning

- ‘Operations’, which includes the functions that work to supply products and services for sale. They include: Procurement, Operations Planning and Logistics (the supply chain group); production/operations and technical/engineering

- Facilitating the total S&OP process is a role for the senior (or Master) planner who is typically located within Operations Planning

The S&OP Review process

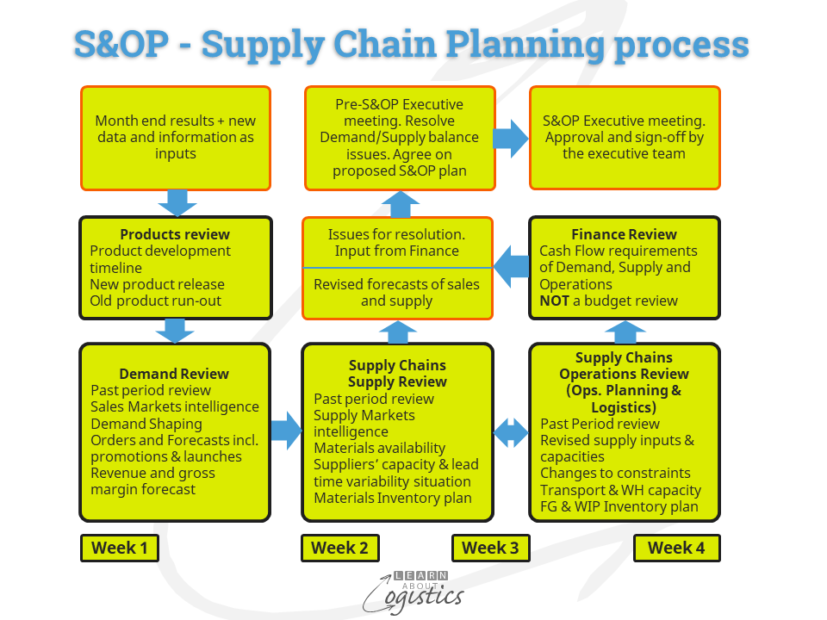

The diagram illustrates that prior to the monthly S&OP Executive meeting, there is a progressive review process across a number of aspects within sales and operations. However, this diagram is a guide which can be modified to suit the requirements of individual businesses.

As S&OP is an inclusive planning process, the IT and HR/Personnel functions are also involved in the final meetings of the process (Pre-S&OP Executive and S&OP Executive).

The Pre-S&OP Executive meeting is attended by the direct reports to the executive team members. Its role is to resolve issues from each of the review meetings. This meeting allows for plans, trade-offs and issues to be modified, accepted and packaged for the S&OP Executive meeting. It includes inputs from Finance concerning the review of revenues, gross margins and cash flow, using inputs from the prior review meetings.

The chairperson for the S&OP Executive meeting is the Profit & Loss (P&L) responsible manager (a division, country, site etc.). The objective is to have the executive group agree on an achievable plan. As the focus and needs of individual functions differ, the chairperson must ensure a balance between opinions, perceived power and status of the disciplines.

The senior management team attends the S&OP Executive meeting, with attendance and participation a part of each manager’s performance measure. If the P&L responsible manager is unable to chair the meeting, it is rescheduled. No substitutes are allowed, as it can become a habit and the S&OP implementation will fail through a lack of commitment.

At the S&OP Executive meeting, the management team ‘signs-off’ for the updated S&OP; so taking responsibility to collectively rectify major variances against the plan. This reduces the ‘finger pointing’ and recriminations so prevalent within businesses where supply chain activities are planned in silos.

Given the heightened importance of supply chains due to disruptions caused by the pandemic, it is time for supply chain professionals to propose and sell the value of implementing the S&OP process in their organisation. But, promotion of the concept must emphasise that the objective is to improve the tactical planning process for the organisation’s supply network.