Planning for Availability.

Providing Availability is what Logistics does. The role of Logistics is ‘the time related positioning of items and resources that provide Availability of goods and services for customers’. Availability is achieved through four planning (thinking and calculating) functions:

- Customer Service logistics – planning inventory, distribution, storage and transport

- Conversion logistics – planning product manufacturing or the final assembly, pack and test of component inputs to meet local requirements

- Support logistics – planning the post-sales support and service of products. Also the planning for life cycle support of an organisation’s internal infrastructure and capital equipment. In the military this is referred to as Integrated Logistics Support (ILS) and Logistics Systems Analysis (LSA)

- Reverse logistics – planning the re-purpose goods (including disposal) through the return of items

Scheduling activities to meet the Availability plan can be done by the Logistics team(s) responsible for physical (doing) activities.

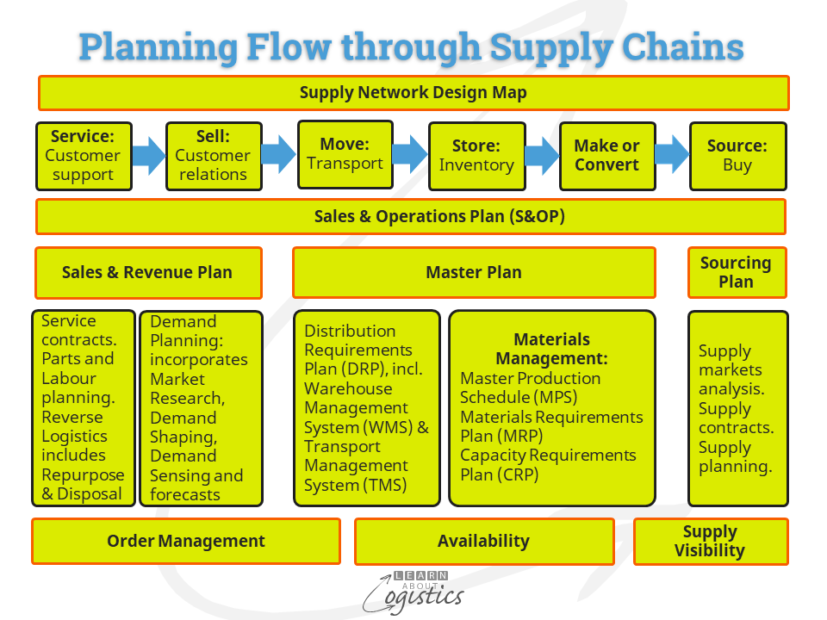

The diagram provides a view of planning activities through an organisation’s supply chains, although all of the associated IT applications may not be implemented, depending on the size and type of business. The diagram commences on the left side with the customer and moves through the Core supply chains to sourcing products, materials and services.

The diagram identifies the preferred structure of the Planning Flow. This is based on the Design Map of your Supply Network; from customers customers to suppliers suppliers. It provides the knowledge base for subsequent planning processes. As I often remark, the Sales and Operations Plan (S&OP) is the hub for planning an organisation’s activities, Output from the S&OP becomes input to three function planning processes; the Sales & Revenue Plan, the Sourcing Plan and the Master Plan. I view the Master Plan as the heart of the organisation, because its role is to plan the flow of individual items (SKUs) through the veins of an organisation’s processes.

The diagram indicates that the Master Plan incorporates (using generic terms) the Master Production Schedule (MPS), Materials Requirements Plan (MRP), Capacity Requirements Plan (CRP) and Distribution Requirements Plan (DRP). The Master Schedule provides inputs for the MRP, CRP and DRP plans and schedules.

The complexity and use of each application depends on how an organisation structures its business – in response to market signals (i.e. demand pull) or produce/import what it forecast to sell (i.e. product push). However, the more global an organisation’s supply base, with longer lead times and higher minimum order quantities, the less reliance there will be on pulling materials in a ‘Just in Time’ style through the supply chain processes.

Product-based operations are structured to address broad market segments: engineer to order (ETO); make to order (MTO); assemble to order (ATO) and make to stock (MTS). Each requires a different approach to structuring the bills of material (BOM) for products, which are used for calculating the dependent demand items to be made or purchased.

In each planning period, the Master Plan takes the agreed S&OP plan as its primary input. The aim of the Master Schedule is that planned outputs will balance the order requirements from customers and sales and provide a level of stability for importing, manufacturing and distribution. Planned safety inventory is used to compensate for the occasions when actual demand exceeds the capability to produce products or acquire imports.

An ‘unstable’ Master Schedule exists when there is inadequate safety inventory and the enterprise is changing short-term schedules to meet customer orders. The cause is often an inadequate forecasting system and a failure to measure and act on the ‘forecast error’. To achieve a more stable Master Schedule, the planning horizon can be divided into agreed ‘freedom to change’ periods – the closer to the present time, the more restrictive are the rules concerning changes to schedules. Of course, the rules must be enforced and not open to dispute by marketing directors!

Providing Availability

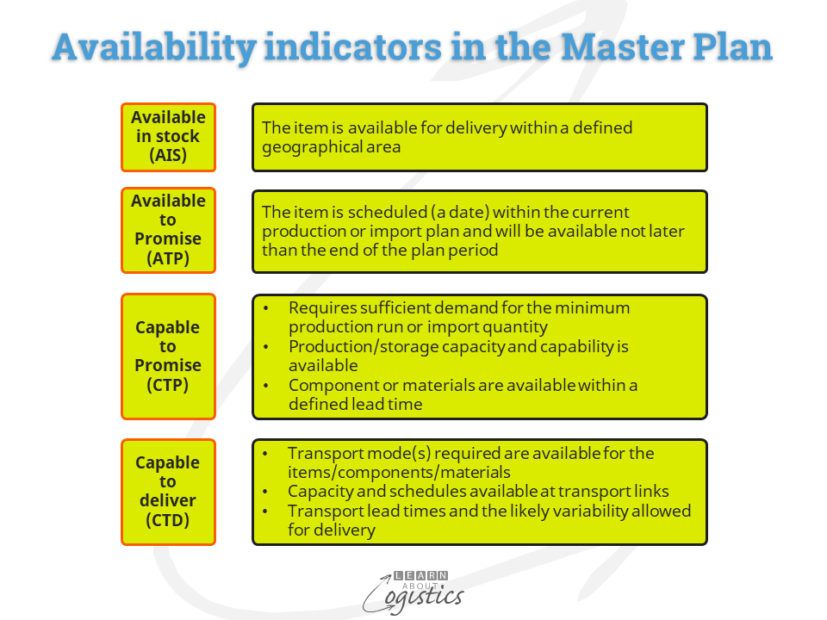

Providing Availability does not mean that all products are available all the time. Instead, an organisation has a planning capability to identify the status of items for the Order Management department. Logistics needs to report the Availability of product groups or stock keeping units (SKU) that are within each of the categories shown in the diagram below:

The objective of planning is to enhance the organisation’s view of real demand for its products and services, to improve response and therefore provide a higher level of Availability. Because the organisation structure for the majority of enterprises is function based and not aligned to flows through the business, responsibility for the three planning processes can be divided. Also, the architecture of the associated applications may not provide inter-operability of data and information between the plans. If so, achieving the three outputs of Order Management, providing Availability and having Visibility of supply, becomes more difficult.

This situation has existed for all the time I have been associated with supply chains, so is unlikely to dramatically change in the next five to ten years, even with technology developments. Improvements in planning supply chains will occur, but most likely in areas within an organisation’s control (that is, not dependent on co-operation with other parties in the supply chains). Given the pressures of shorter lead times and quicker deliveries, the focus for improvement should be to enhancing the ‘demand pull’ planning capabilities that enable improved response to market signals. The four areas for improvement are suggested as:

- Sales & Operations Planning

- Inventory positioning in the supply chains

- Decoupling points between product push and demand pull in product and materials flow and

- Demand shaping to improve customer and/or consumer demand

Planning is a critical function within Logistics. While the execution schedules can be performed as part of a Logistics Service Provider (LSP) contracted service, planning should remain as intellectual property within your organisation.