Supply Chain strategy objectives.

A Supply Chain strategy is a rare document within organisations. In the previous blog-post Developing your ‘connected’ Supply Chains strategy, it was noted that views in some organisations are that elements of Supply Chains are only cost driven and those elements are often a part of other functions. Therefore, few companies have a strategic plan for their Supply Network – a critical part of the business.

However, if a Supply Chain strategy document is required, then a Logistics executive is likely to be ‘volunteered’ to do the work. Part of the discussion in the blog identified the difference between functional strategic plans for running the business and a separate strategy for changing elements of the business (or the total business). The first task is therefore to review the functional strategic plans for running the business. The plans that contain information concerning the organisation’s supply chains will provide the current supply chain model (how things are done), process improvements and cost reductions to be implemented over the next two to three years. This information enables construction of a strategy document for running the supply chains of the business.

The next stage is developing the strategy for changing the supply chains, to better address the challenges facing the business. Before getting into methodologies, applications and technologies, identify the broad objectives that the strategy exercise hopes to achieve. Examples for achieving a ‘connected’ Supply Network are to:

- Establish a common understanding in the organisation concerning the meaning, structure and role of supply chains and networks and their value in improving the customer experience with the organisation

- Identify the desired visibility requirements (for items, money, transaction data and information) through the core and extended supply chains

- Establish the extent of cross-function alignment (co-operation, co-ordination and collaboration) required in the organisation

- Use ‘one version of the truth’ by employees, customers and suppliers. Identify the processes for access to and use of data and information through the organisation’s core supply chains

Start with Logistics

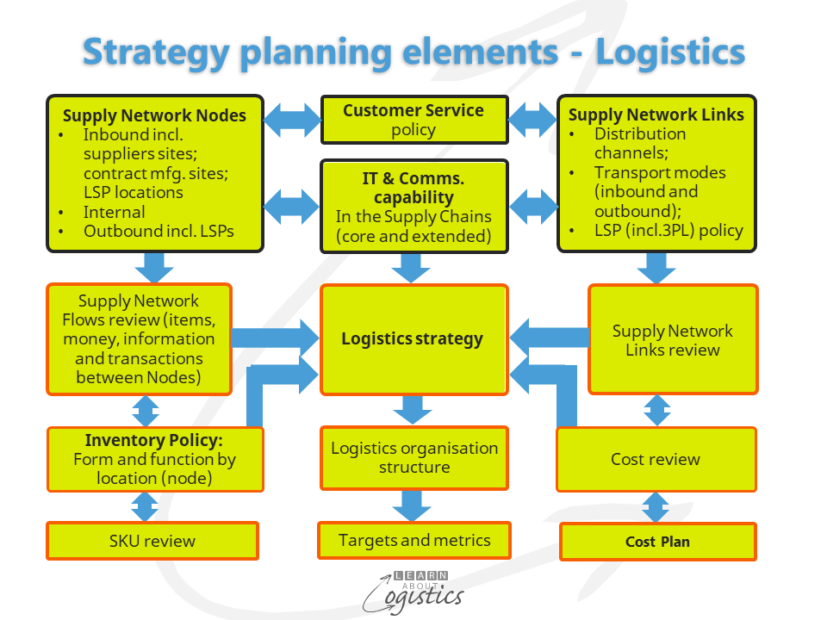

The diagram below identifies the elements of a Logistics Strategy. As you consider each element and the inputs required, note the connections required with other functions.

The need for additional inputs requires the Logistics executive to liaise with multiple functions. This illustrates the learning that successful supply chains require people to work across functions:

- Customer Service policy is established by Marketing

- Supply Network Nodes and Links requires input from Procurement concerning suppliers and their capabilities and Marketing/Sales concerning customers and their needs

- IT and Communications capabilities is established by corporate IT

- SKU review and Inventory policy could (or should) be undertaken by Operations Planning

- Cost Plan and Review requires assistance from Finance and Accounting

Two areas that provide a challenge in the cross-function discussions are a cost driven focus and IT systems. To those who consider that elements of supply chains are only cost driven, guide the discussion away from cost to increasing value for customers and consumers. To those who consider that the business is already ‘integrated’ because an ERP system has been installed (but too often not correctly implemented), illustrate how an ERP system provides a corporate record of transactions (it is the backbone system), The ERP backbone should be supported by specialist Supply Network Analysis and Planning (SNAP) applications that access the base data from the backbone, complete their tasks and send the solution back to the ERP backbone for action and consolidation.

Prior to visiting other functions, document and analyse the data and information that Logistics can access concerning: Nodes, Links and Flows of supply chains that make up the Supply Network. This will commence building the Supply Network Map, which provides a repository for information about how the organisation’s Supply Network actually works. Examples of the information required are:

- Details of core suppliers and customers and their respective operational location

- Segment customers to improve customer service (and to assist calculating the ‘Cost to Serve’)

- Ownership, control and influence by parties at critical nodes and links

- Customer demand patterns by product group

- Contractual responsibilities to satisfy customer demands and meet supply needs

- Contractual responsibilities at critical Nodes

- The direction and volume of materials flowing through each Node in each Supply Chain

- Inventory at each node

- Form: raw, semi-finished (components, assemblies), finished products

- Function: cycle inventory, seasonal and promotions stock build, safety stock, Vendor Managed Inventory (VMI), customised products, postponement

- Variables – factors that can change the physical or financial values at a node

- Identify for Planning the Order Penetration Points – where orders meet the plan (Planning is driven by either forecasts or demands)

- Inventory at each node

- Estimates of Value Added to an item at each Node

- At each Node and Link identify the Sustainability Objectives and Supply Chain Risks (uncertainties) – complexity, variability and constraints. Include Risks within the organisation, where problems (and therefore poor perception) may occur; typically around the:

- Ease of buying items from your organisation

- Process for Tier 1 and other suppliers to sell products and services to your organisation

- Warehouse and Transport (3PL) suppliers planning and scheduling

- Internal decision process to change supply chain processes

Building a Supply Network Map provides a customer-centric view of each supply chain through addressing customers’ demand patterns. Unfortunately, a business with the most efficient supply chains (that is the lowest total cost per pack unit e.g. case or shipper) is unlikely to be the most effective. The objective in supply chains is to improve customer service. So, while cost reduction is expected, the focus must be on balancing customer service targets, inventory turns and the Supply Network Return on Invested Capital (ROIC).