Improving your Supply Chains.

Although articles tell us of new challenges and exciting technologies for supply chains, I find that actual challenges and steps to solutions have yet to dramatically change.

I was recently cleaning a computer disc of past PowerPoint presentations. One slide from 2000 listed the discussion points concerning Supply Chain challenges for a Logistics Masters student workshop. The list highlighted to me that challenges for supply chain professionals at shippers and 3PL services businesses have remained remarkably consistent over the past 18 years, except for an additional emphasis on ‘new’ technologies and eCommerce with ‘last mile’ delivery.

A measure of success is how much better the challenges are understood and addressed now than in 2000. For all businesses, the challenges in supply chains are being increasingly influenced by external factors; the most prominent being: geopolitics, environmental concerns, international trade agreements and technology developments. These additional factors are for supply chain professionals to understand and act upon.

Your approach to improvements cannot be ad-hoc. It requires a logical step by step approach, beginning with the fundamental factor in all materials based supply chains, which is Inventory. This is the factor that underpins the effectiveness of all elements in Logistics; without it, efforts to improve Logistics Management are likely to be ineffective. Inventory Management has three elements: Inventory Policy, Inventory Planning and Inventory Control. To improve your Logistics, start at the base, which is Inventory Control and within this is Inventory Record accuracy.

Inventory Record accuracy

The accuracy of inventory items in the raw and packaging material store, production ‘work in progress’ store and of stock keeping units (SKUs) in the warehouse is obtained through counting. Just as the teller in a bank counts your money when it is received and again counts the money (usually more than once) when giving you cash, so the store and warehouse is your organisation’s bank and inventory is the money.

To maintain inventory accuracy, control must be done on a daily basis. As the use of radio frequency identification devices (RFID), attached at the pallet or shipper level, become more common, the counting regime will change. RFID provides the capability for a facility count or spot count of a storage location, whenever required. However, for those organisations that have yet to implement RFID applications, the core control technique is cycle counting.

The basis of Cycle Counting is that, in addition to counting items as they are received and dispatched, selected items held in inventory will be counted each day. The logical basis for selecting items is to base it on the segmentation of inventory. Segmentation of finished goods is typically called the ‘ABC classification’. However, an earlier blog discussed an extended classification of A to F, based on the variability of sales by each SKU.

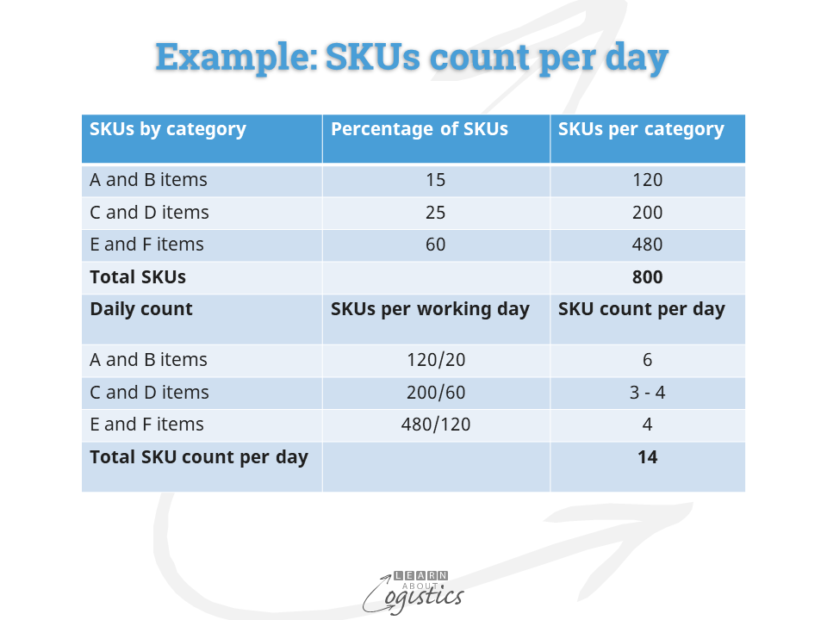

In principle, all A and B items should be counted every month, C and D items within three months and E and F items within six months. Therefore, only a few items will be counted each day, because the Pareto principle (80/20 rule) tells us there will be few items in the A and B categories and many in the E and F categories. An example warehouse could have the following situation:

The SKUs for counting is randomly selected (inventory modules within ERP systems can usually do this or use Excel). The daily count should be undertaken by a senior supervisor, so that inventory accuracy is seen as an integral part of their job,. They receive the list of items to count on arrival at work and while counting, items are not picked or moved.

On completion of the cycle count, the actual and computed totals are compared and if there is a difference for an item, a recount is done. If the second count also shows a difference, the responsible manager makes a decision whether to authorise another count or report the difference to the finance department, for a decision concerning an adjustment to the accounts.

Enhancing the discipline of inventory record accuracy, an additional inventory count of an item is required when:

- the computed total for an SKU is at its re-order point

- the inventory level for an SKU shows zero in the IT system

- goods are required to be put away at a location and it is found that another SKU is stored at the location

- goods are required to be moved from a location and that location is found to be empty

- the number of movement transactions for an SKU within the period exceeds a specific number – a high number of transactions can hide cumulative errors

If inventory segmentation has not been done, then implementation of the inventory record accuracy process will take additional time. The steps required for the process are:

- Inventory record accuracy is incorporated within the performance management system – this requires the senior supply chain executive to sell the concept for senior management recognition and approval

- Allocate responsibility for meeting inventory record accuracy performance targets

- Education program implemented for the stores/warehouse team(s). Influence employees about the need for inventory accuracy and their role in helping the facility meet its performance targets

- Teams review and improve:

- Inventory location plan to optimise storage space

- Item movement transaction process

- Inventory rotation procedures

- Operating manual

- Training in stock count and error correction process

Inventory Record accuracy may be considered a ‘boring’ activity, but it is a vital element of your supply chains. Accurate inventory records are a basic input for Inventory Planning and development of the Logistics strategy, which is a pillar of the Supply Chains strategy.