Technologies and Agile.

Going Agile is not an easy road. The Internet of Things (IoT) is often portraid as one of the technologies that will help to solve manufacturing and distribution problems; for example, a recent promotion for a conference stated that IoT will help provide Agility for businesses and increase the bottom-line (profit). But is this a true statement?

In a closed environment of a factory or warehouse, one of the challenges is managing equipment maintenance – too much and costs increase and not enough will cause unplanned downtime, which could affect affect sales (with cost increase to correct the problems). So, a reasonable objective to deliver maximum asset availability, is to aim for a maintenance, repair and overhaul (MRO) system that is integrated with the facility planning and scheduling system. The MRO system will include equipment performance measurement and analysis, service parts inventory management and maintenance planning and scheduling capability.

A critical element will be equipment performance, but that is not a new requirement. Many years ago, part of the routine for young engineers was to collect and analyse the previous day’s tapes, discs or printouts to identify when equipment would need to be serviced. What was missing was the tight integration with production planning and scheduling.

So, if all the current equipment data in a facility was interfaced through an IoT to a central analysis point, the analysis could well be improved, but unless the organisation has a viable Sales & Operations Planning process and network links between the MRO and operations planning systems, then the IoT would not help to provide Agility for a business and certainly not increase the bottom line.

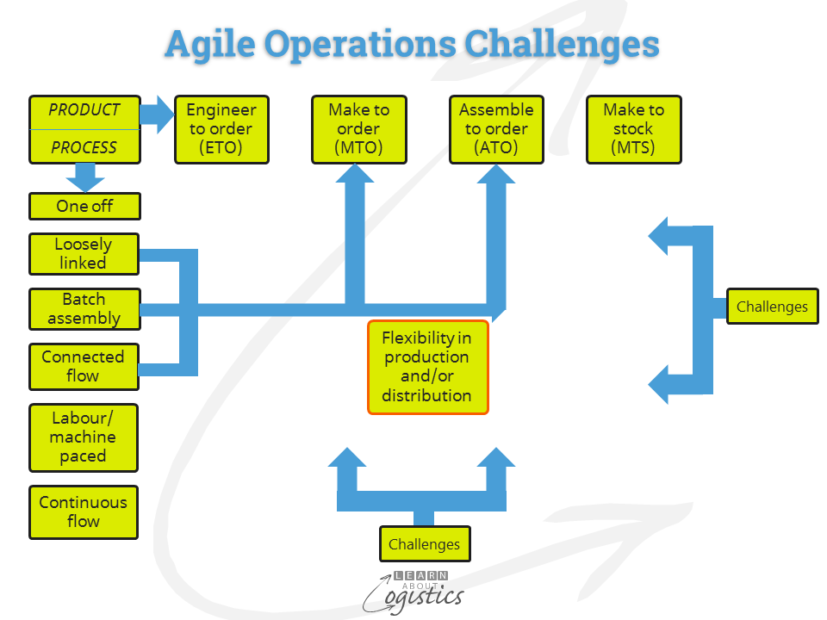

Last week’s blogpost discussed the position of Agile operations within the Product – Process mix of options to produce and distribute goods and services. The blog concluded with the observation that “Agile requires an ‘effective’ rather than ‘efficient’ focus, which will take time for acceptance by senior management and then for the implementation. As with many aspects of supply chains, Agile is easier said than done!” Before thinking about IoT in relation to Agile, there are more fundamental factors to consider.

Challenges when implementing Agile

The diagram indicates challenges for your organisation when producing Make to Order (MTO) and Assemble to Order (ATO) items, using loosely linked, batch assembly or connected flow processes. The previous blog identified some of the challenges at the planning level and this discussion considers challenges at the scheduling level.

Highlighting the difference between MTO and ATO products:

- Make to Order (MTO) is the adaptation of pre-designed products – providing a design and manufacture service for options to the base products. The base item could be produced in advance of orders, but this depends on:

- the variability of demand for the base item

- the inventory value of base items

- the range and complexity of options

- the expected (by customers) delivery lead time

- Assemble to order (ATO) is to assemble discrete or ‘mix and stir’ process (non-discrete) products to order; based on specific orders from either customers or the sales department for catalogue or recipe products. The business will make or buy materials, components, sub-assemblies, packaging and options to:

- Immediately assemble into finished goods and deliver, using ‘just in time’/lean flow manufacturing processes

- Assemble and deliver purchased or previously produced and stocked discrete sub-assemblies or ‘mix and stir’ ingredients. This is an example of ‘form postponement’ or ‘delayed configuration’

Product challenges:

- Emphasis by marketing and sales to increase the range of items sold and so appeal to all market segments. Also, products can be sold and delivered in any (or at least smaller) quantities

- Reduce the total investment in inventory. This is achieved through holding items at their lowest value added state, but requiring minimum time to complete manufacture and deliver

- Consideration of contracting (to a flexible schedule) for the production of sub-assemblies. This may incur intellectual property (IP) challenges for production

Outcomes from these actions will be an increase in the importance of Procurement and scheduling complexity. Both require more capable people, possible implementation of more focused IT applications and a greater recognition of risks (uncertainty) in the organisation.

Process challenges:

For scheduling production, there is the challenge of reducing changeover times from one item to another. In the 1990’s there was considerable promotion of the single minute exchange of dies (SMED) concept, which remains a valid objective when emphasising Agile. This can require a re-design of the operational layout

There is also the challenge of operations sequencing and asset utilisation. Will the business be Agile with all items, or a selected group? The sequencing must take account of priority rules; for example with painting and plastics extrusions there is colour sequencing from white, through the range, to black, then clean out and start again with white. These challenges can influence bottlenecks, therefore management of Constraints in the process must be a part of scheduling for Agile.

If the process includes ‘connected line flow’ operations, then mixed model line balancing is important, especially between assembly and final packing. Kanban control of materials and components is required. For process products, the emphasis is on flow control.

The process of materials and items moving through a supply chain has fairly standard data transaction points:

- link with transport schedules and book space on ships, trains or aircraft

- book road trucks or space on trucks

- track movement of goods on their transport modes

- payments

- arrange financing of shipments – import or export

- pay for received items

- pay freight invoices

- link to customs and customs brokers – pay import duties

- link to insurance companies – pay premiums

- register receipt of shipments

- track items in warehouse

- locate and count inventory

- notify suppliers concerning non-conformance and rectification of shipments

- plan, schedule and register order deliveries to customers

- receive notification of non-conformance of a delivery

- collect money from customers

With a move to Agile, your organisation will need to consider each transaction point and what must be done to reduce the time taken and increase responsiveness. This review could be done in conjunction with one or more 3PL’s and other Logistics Service Providers (LSPs) that your organisation contracts with, which increases the complexity and time.

In this list of challenges, IoT or other technologies are not mentioned. Although technologies that have been rigorously selected and correctly implemented can assist an Agile organisation, if the basics requirements of Agile have not been recognised and implemented, no amount of technology will improve the situation.