Achieving the perfect order.

An empty shelf at a supermarket results in dissatisfied consumers, less sales by the retailer and if the item is not available at the retailer’s warehouse, then questions of the supplier, For logistics, the overriding requirement of your customers is that each of their orders is a ‘perfect order’.

A perfect order means:

- the initial customer order has not been modified because:

- sufficient inventory is not available

- particular SKUs are not available

- deliveries cannot be made when required by the customer

- delivery of the order is ‘in full’

- receipt of the order by the customer is ‘on time’ and

- all documents (electronic or physical) are accurate

The capability of your business to provide a perfect order is the measure called DIFOTA – ‘delivery in full, on time with accuracy’. And all the requirements of a perfect order are the responsibility of Logistics.

How should we measure the achievement towards providing the perfect order? The measure of perfect customer orders received and completed is called the Fill Rate (complete orders/total orders). Some businesses use the Backorder Rate (BOR), which measures the percentage of unfilled orders/total orders.

The measure of ‘delivery in full, receipt on time and accuracy of documents’ is called DIFOTA. It is not a measure of operational performance for the previous shift, yesterday or last week. Instead, it is concerned with the probability of your business achieving a perfect order at the time of calculating the measurement. Depending on the business, it could be a weekly or monthly update.

Yesterday might have been a great day, with every order picked and delivered without a problem; however the probability of that happening every day maybe decreasing. If you are not aware of this situation, it could come as a surprise when bad days occur more often than good days – and it is surely someone’s fault!

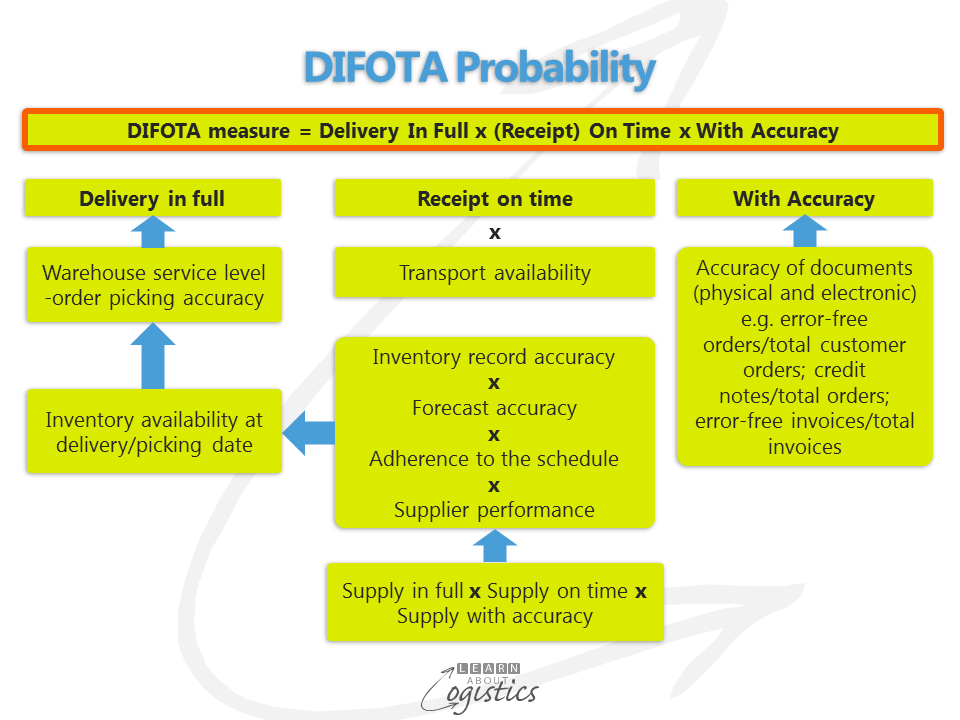

Instead, through using DIFOTA, the trend in potential performance is evident, so that action can be taken to correct areas of weakness. As I note in my book A Framework for Supply Chains, you can structure DIFOTA similar to the diagram:

Calculating DIFOTA

The DIFOTA probability is calculated through multiplying the three performance measures (in full, on time and accuracy). For example, if each is calculated at 95 percent, then by multiplying the three, the DIFOTA probability is 86 percent. This means that approximately one delivery in seven is likely to have a problem – and that is with a very good result! Your business will be about average with a DIFOTA of 50 percent and do not be surprised with results of less than 30 percent.

To achieve a high DIFOTA depends on the performance of the subsidiary factors in each column, so working through an example:

Delivery – In Full

- Inventory availability: The product lines, or SKUs, which are immediately available to fulfil the customer order divided by the total lines ordered = 80%

- Inventory availability is calculated by multiplying together the four factors of: inventory record accuracy, forecast accuracy, adhering to the schedule and supplier performance

- Supplier performance is calculated from the DIFOTA measure for each supplier

- Warehouse service level: If the order has 10 SKUs totalling 100 units and 9 SKUs totalling 95 units are dispatched, the line fill = 90%; unit fill = 95% and order fill = 0%. Service level = 85.5%

In Full performance: 80% x 85.5% = 68.4%

Receipt – On Time

- For 100 orders, 90 are delivered on time = 90%

- Transport availability: If 10 trucks are required (own fleet or 3PL) and 9 are available = 90%

On Time performance: 90% x 90% = 81%

Accuracy of documents

- Order entry: The number of error-free orders divided by the total number of customer orders = 97%

- Customer claims: The number of credit notes issued to customers (based on wrong delivery address, wrong quantities, wrong time etc.) divided by the total number of orders = 97%

- Invoice accuracy: The number of error-free invoices divided by the total number of invoices = 98%

Accuracy of documents performance: 97% x 97% x 98% = 92.2%

The measure of DIFOTA is: In full 68.4% x On time 81% x Accuracy 92.2% = 51 percent, which is a typical measure for a logistics operation in the consumer packaged goods (CPG) and fast moving consumer goods (FMCG) sectors.

What measures should you be aiming for in the quest to achieve perfect orders?

- Delivery in full = 99 percent, with inventory availability at 95+ percent

- Receipt on time = 99 percent

- Accuracy of documents = 99 percent, with order entry at 99 percent and invoice accuracy at 99 percent

Your DIFOTA objective should be greater than 91 percent.

DIFOTA is the measure in which each step in the process of handling a customer order has an affect on the overall probability measure. Each of the measures that affect DIFOTA are therefore linked and improvements should be addressed within an overall ‘one plan’ approach, rather than the more typical piecemeal ‘department efficiency’ approach of many businesses.

DIFOTA, together with the ‘cost to serve’ calculation, is a prime measure of logistics performance in fulfilling its objective to provide availability of products for customers. Improving DIFOTA means that your business is providing superior customer service against competitors. This provides a competitive advantage, because service (and services) are more difficult for competitors to copy.