News to affect supply chains.

Three articles this week provided input into a picture of supply chains in the future. One article discussed the recently agreed (but not ratified) Trans-Pacific Partnership (TPP), a trade facilitation pact between 12 countries of the Pacific rim. The second talked about the benefits of incorporating the Internet of Things (IoT) into supply chains. The third asked why world trade had decreased by about 10 percent over recent years when there was not a global economic downturn.

There is some linkage between these articles; for example, trade facilitation requires visibility and the IoT will provide tools to this. But how long before this happens? The TPP is intended to free-up trade in goods and services, through the reduction in tariffs and quotas on imports. However, four factors question the impact of the TPP on supply chains (if it is eventually ratified by all countries):

- The changes to tariffs and quotas will not occur upon ratification of the agreement, but over a period extending 10 – 15 years

- Non-tariff restrictions are not eliminated and countries are increasingly using these, rather than tariffs, as protection for their domestic industry

- Although the publicity has been about the effects on manufactures and agriculture, the TPP agreement recognises the increasing importance of services, including information technology services, all of which are nearly borderless in their operations. This could be one of the reasons for the reduction in international trade

- A substantial portion of global trade is between related parties. These international businesses are able to adjust materials, components and finished product items and volumes to suit the clauses in international trade agreements that are in effect at the time of planning future sales of the end product

Instead of getting excited or despondent about trade agreements and other events, logisticians should continue to build an understanding of their supply network to build-in sufficient resilience and responsiveness for the future.

Thoughts about your supply chain organisation

Supply chains within your network operate as flows of items, money and information. To understand and work with these flows, your internal organisation needs to reflect the effect of the flows on the inbound, internally and outbound operations of your business.

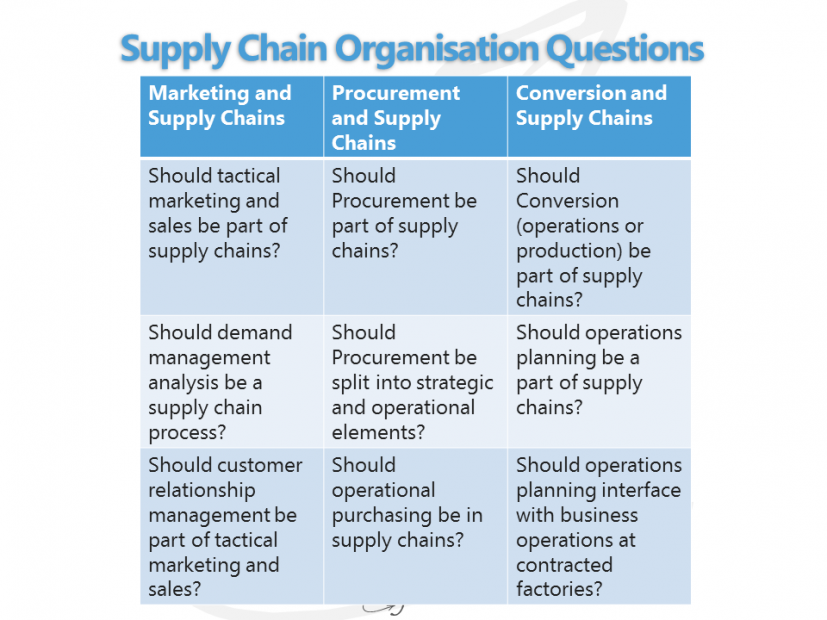

This leads to some questions about what capabilities (in addition to Logistics) should or should not be within a supply chains function. Examples of questions are:

After these (and other) core questions have been answered, come the additional questions. These concern business elements that could be within your supply chains:

- If operations planning (but not scheduling) is part of supply chains, will the senior planner drive the Sales & Operations Planning (S&OP) process. This will require supply chain analysts to turn data into information

- Two measures of supply chains performance are working capital and cash flow; supporting these measures are the approval of credit for customers and possible financing arrangements for suppliers. Should there be a supply chain finance capability?

- When relating to external parties there are legal and governance requirements. Risk identification is gaining importance in supply chains, as are identifying and managing compliance with international and domestic laws and regulations. Should there be a supply chain legal capability?

- Supply chains are IT centric and this will increase. Applications software and communications integration and interfacing; mobile computing and sensors on equipment for ‘in transit’ visibility (the Internet of Things), are all part of supply chains. Should there be a supply chain IT capability?

If any are answered in the affirmative, should the capabilities be a part of the supply chain function, or just have a dotted line (matrix management) reporting to supply chain? Operating within the context of supply chains does not imply that the person responsible for supply chains must take executive responsibility for all elements. The important factor is that the senior supply chain person must be responsible for the performance of the three flows through the supply chains. This means the potential to optimise the overall result (through not optimising individual functions) and therefore have influence in improving the corporate or business strategy.

The supply chain organisation structure for your organisation can vary, depending on the enterprise, industry and cultural setting. However, as business and industries move into changing situations noted at the start of this blog, senior management should match the supply chain organisation to the following questions:

- What decisions are critical within the supply network?

- Where in the supply chain organisation should these decisions be made?

- Do the people that are expected to make the decisions have sufficient authority?

- Have the decision makers in supply chains received the appropriate training to make good decisions quickly?

Your supply network will never become ‘integrated’, as it comprises independent organisations with their own policy and objectives. Therefore, the aim should be to understand the supply markets that your organisation relies on and have the ‘core’ supply chains responsive to your customers needs, through planning and systems.