Inputs to your Business Plan.

There is not a ‘best’ way to design your Supply Chains and plan Logistics operations. It depends on multiple elements, including the business model, approach to markets and geographical locations, industry type, products and processes. But, you can use the ‘One Plan’ approach for a structured way to identify the Supply Chain objectives, structure and operations in your enterprise.

In the post ‘Use external inputs to your Business Plan with care’, the challenges of incorporating external data into your Business Plan were discussed. The other key input to the Business Plan is the Business Model. For a shipper or brand company this is the why and how description of your organisation for achieving its overall goal and business objectives.

Your organisation’s view of its markets

Developing a Business Model is outside the scope of this post, but Supply Chain professionals should identify elements in your organisation’s model that could affect the behaviour of Supply Chains:

How the enterprise views its markets, because businesses in the same industry with similar products will function differently:

- Domestic only – operates within a local or country based market

- Multi-domestic – the domestic business model is duplicated in other countries

- International – all countries are treated as subsidiaries of the head office, with policies and plans centrally generated; however, products and operations may differ in individual countries

- Global – one company image, with standard product lines and processes. A few owned or outsourced manufacturing facilities serve all markets

- Multinational – the brand image is important, but the approach is ‘think global, act local’. Balance global and local sourcing, manufacturing and distribution

Overlay the approach to markets with how responsibility for sales and profit is structured:

- Divisions or sales companies, each having their own sales teams. These could compete with other divisions in the same organisation

- Geographic areas in which region or area managers are responsible for all that happens within their allocated geographic zone

- Production group, whereby products within a group are manufactured in designated locations and sold to the sales group at an internal transfer price

The market elements identified above will influence how your organisation will respond to pressures on the core Supply Chains (inbound, internal and outbound). To gain an overall view of how the organisation interacts with the outside world requires mapping the Supply Network.

Supply Network mapping

The Supply Network contains your core and extended Supply Chains (the extended are nodes and links outside level 1 customers and suppliers). Mapping provides a visual structure of the business interactions, identifying:

- Customer demand patterns through each Supply Chain

- Where value is occurring through each Supply Chain, enabling rationalisation of redundant nodes and links in the Supply Network

- Weak links in each Supply Chain, together with benefits and costs of alternatives

Supply Network mapping requires the collection of extensive information and data, including:

- Details concerning the nodes and links in each Supply Chain, including the degree of ownership or control and capacity utilisation

- At each node, the intended form and function of inventory:

- Form: raw and packaging materials, semi-finished sub-assemblies, finished products

- Function: cycle inventory, seasonal build, safety stock, Vendor Managed Inventory (VMI), postponement and custom build products

- The flows (direction and volumes) of items, money and information through each Supply Chain

Using this information enables Supply Chain professionals to:

- Provide achievable sustainability objectives for the organisation

- Design customer segments by Supply Chain service requirements

- Identify planning decoupling points and

- Identify potential risks, constraints and the amount of possible variability within each Supply Chain

This enables the data concerning items and volumes to be translated into ‘what-if’ profitability analysis, for use in the Business Plan.

Industry types in Supply Chains

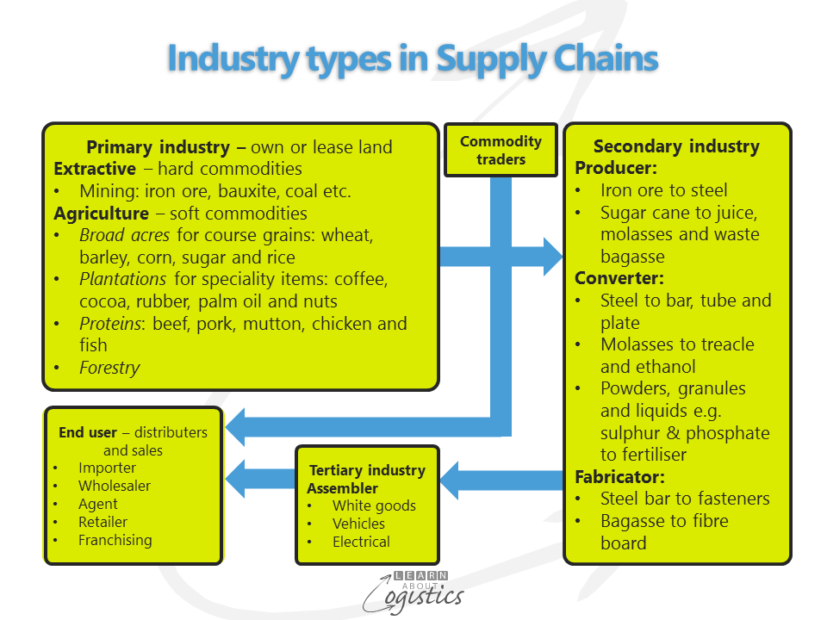

An additional input to your organisation’s Business Model is the industry type(s) in which the organisation is engaged, identifying the resulting influences and pressures throughout the Supply Network. Examples of industry types are:

Even in primary industries there are inbound supply chains, such as equipment, fuel, seed and fertiliser. Also, the effectiveness of their outbound Supply Chains is influenced by the availability and capacity of transport modes to move bulk materials, especially at harvest time and when there is high international demand for minerals.

Discrete and bulk items require very different handling, storage and transport; some businesses may handle bulk materials as inputs and discrete products as outputs. An example is inbound bulk granulated sugar, cocoa and glucose mixed and finished as discrete confectionery products.

Bulk products (liquid, gas, powder or granules) have flexible characteristics:

- size of the product is the batch quantity

- form of the product is the container holding the item

- the measure can vary, dependent on factors such as potency and specific gravity (SG)

Conversely, the identifiers for discrete products are:

- Solid to touch

- Have their own form

- Uniform in shape

- Measured as ‘each’

The Business Model is a key input to the Business Plan, which is the first stage of the One Plan approach. As the global influence of Supply Chains is so pervasive, businesses should review the model (annually?) and if need be, adapt the Business Model to take advantage of changes in Supply Chains.